Vibrating Conveyor

Showing all 21 results

- Conveyor, Industrial Machinery, Vibrating Conveyor

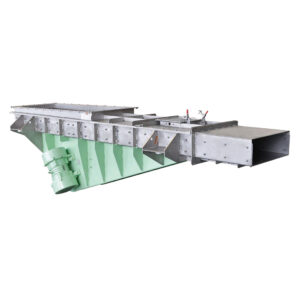

Balanced conveyor MVCB – SINFONIA TECHNOLOGY CO. LTD.

Conveyor, Industrial Machinery, Vibrating ConveyorBalanced conveyor MVCB – SINFONIA TECHNOLOGY CO. LTD.

0 out of 5(0)Simple vibration pollution prevention type.

The balanced conveyor is a vibration-prevention type that utilizes an exceedingly simple mechanism to prevent vibration from being transmitted to the mounting foundation. Vibration reaction forces are reduced by effectively balancing the trough and counterweight, and the entire unit is supported by anti-vibration springs, significantly reducing vibration transmitted to the foundation.

SKU: n/a - Conveyor, Industrial Machinery, Rubber Belt Conveyor, Vibrating Conveyor

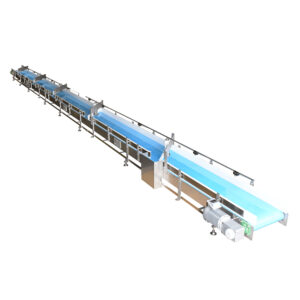

BELT CONVEYOR – Sugiyama Heavy Industrial

Conveyor, Industrial Machinery, Rubber Belt Conveyor, Vibrating ConveyorBELT CONVEYOR – Sugiyama Heavy Industrial

0 out of 5(0)Capable of transferring large quantities of material over long distances without applying external force to the material. The bottom of the belt is V-shaped to prevent material spillage during conveyance, and the belt with cleats can handle inclined conveyance.

Ideal for processing of horizontal conveying with small to large capacity. Its simple structure and low cost make it an attractive option. Various belt shapes, such as side skirt type, V type, pipe type, and with cleats, can be selected according to the material to be conveyed.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

BM conveyor – SINFONIA TECHNOLOGY CO. LTD.

0 out of 5(0)Fully balanced type with high efficiency.

The BM conveyor is a conveyor that utilizes a completely balanced binder system.

The center points of the two upper and lower troughs, connected by springs, are supported on a fixed frame, and the upper and lower troughs are vibrated by the rotary motion of the motor and the resonant motion of the springs.SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

DENSE-OUT® Vibratory AIR Separator – Action Vibratory Equipment

Conveyor, Industrial Machinery, Vibrating ConveyorDENSE-OUT® Vibratory AIR Separator – Action Vibratory Equipment

0 out of 5(0)Shake & Sort With AIR!

The DENSE-OUT® is a dry classification tool that utilizes vibration to stratify and air to separate bulk materials, primarily based on differences in density. This tool helps to produce cleaner and more valuable products. Single, double, or triple air knife models are available to meet your separation needs.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

Electromagnetic Vibrating Conveyor Multi Electromagnetic Conveyor – URAS TECHNO CO. LTD.

Conveyor, Industrial Machinery, Vibrating ConveyorElectromagnetic Vibrating Conveyor Multi Electromagnetic Conveyor – URAS TECHNO CO. LTD.

0 out of 5(0)The Uras Multi Electromagnetic Conveyor is able to convey materials across long distances without transmitting vibration to the work floor.

The Multi Electromagnetic Conveyor utilizes electromagnets as a source of linear vibration to transport materials. Its design is incredibly simple, consisting of only a trough, frame, and balancer. Conveyors are available in lengths of 3, 4, or 5 meters, and multiple units can be combined for a maximum length of 30 meters. Smooth starting and stopping ensures minimal transmission of vibration to the ground, making the Electromagnetic Multi-Conveyor highly conducive to a safe work environment.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

Flat Spring Conveyor FSL Models – Action Vibratory Equipment

Conveyor, Industrial Machinery, Vibrating ConveyorFlat Spring Conveyor FSL Models – Action Vibratory Equipment

0 out of 5(0)They provide a rugged and economical answer to many bulk material conveying and processing jobs.

All FS conveyors incorporate the natural frequency principle, controlled vibration, positive eccentric drive, and standardized sectional construction.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

MV conveyors MVC – SINFONIA TECHNOLOGY CO. LTD.

0 out of 5(0)Low-cost type with simple and robust construction.

The MV conveyor is a straightforward conveyor in which a trough supported by springs is vibrated by the rotary motion of an electric motor. Due to its uncomplicated and sturdy structure, it is especially suitable for special applications such as drying and cooling during transportation.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

Rubber-spring conveyor HRC – SINFONIA TECHNOLOGY CO. LTD.

Conveyor, Industrial Machinery, Vibrating ConveyorRubber-spring conveyor HRC – SINFONIA TECHNOLOGY CO. LTD.

0 out of 5(0)Variable vibration angle and low floor type.

The rubber spring conveyor is a low-floor type conveyor that enables the vibration angle of the trough, which was previously hard to adjust, to be adjusted freely according to the material to be transported and the purpose of transport. The source of vibration is a motor-driven circular vibration of an unbalanced weight, which is amplified through a resonating rubber spring with a variable vibration angle to vibrate the entire trough evenly and stably.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

RV conveyors RVF – SINFONIA TECHNOLOGY CO. LTD.

0 out of 5(0)Forced vibration type suitable for adhesive materials.

RV conveyors are vibratory conveyors with a vibration motor (RV motor) affixed to the trough as the source of vibration. The vibration motor produces vibration through the rotational motion of unbalanced weights attached to the rotary shaft of the electric motor, which directly imparts vibration to the trough.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

Shaking conveyor SHK – SANEI Co.Ltd.

0 out of 5(0)Maintenance is minimal, production is maximum.

One of the essential tasks in metal processing is to discard scrap from lathes, presses, and other processing machines. We have designed a conveyor to make this task more efficient.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

Shaking Stainless Steel Conveyor – Ishii manufacturing Co.Ltd.

Conveyor, Industrial Machinery, Vibrating ConveyorShaking Stainless Steel Conveyor – Ishii manufacturing Co.Ltd.

0 out of 5(0)This makes it easy to dry and hygienic by inhibiting the growth of bacteria.

The utilization of a single material, food-grade belt, and the utilization of resin alone, without fibers, prevents the absorption of moisture and oil.

SKU: n/a - Conveyor, Industrial Machinery, Spiral Conveyor, Vibrating Conveyor

Spiral elevator RVES – SINFONIA TECHNOLOGY CO. LTD.

Conveyor, Industrial Machinery, Spiral Conveyor, Vibrating ConveyorSpiral elevator RVES – SINFONIA TECHNOLOGY CO. LTD.

0 out of 5(0)Vertical transport type with the smallest footprint.

The spiral elevator combines a drive unit with a vertical spiral trough and utilizes vibration to transport all kinds of powder and granular materials vertically, while simultaneously cooling and drying them. The same principle can also be applied to downward conveying.

SKU: n/a - Conveyor, Industrial Machinery, Spiral Conveyor, Vibrating Conveyor

Spiral Elevator Vibro Lift – URAS TECHNO CO. LTD.

Conveyor, Industrial Machinery, Spiral Conveyor, Vibrating ConveyorSpiral Elevator Vibro Lift – URAS TECHNO CO. LTD.

0 out of 5(0)The Vibro Lift has a small footprint and is useful for cooling materials while conveying vertically.

The “Vibro Lift” utilizes two Uras Vibrators to generate a rotational vibration which transports materials upwards through a helical trough. It occupies minimal space and is easy to clean. The expansive surface area of the trough makes it suitable for cooling, heating, drying, or cleaning materials. An optional water jacket beneath the trough makes it an ideal tool for cooling.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

SUB-PAN FREE® – Action Vibratory Equipment

0 out of 5(0)A Common Sense Solution

The SUB-PAN FREE™ TAPER-SLOT® Vibratory Screen is the ideal choice for sticky applications, eliminating material accumulation, wear, and sub-pan upkeep. Without a sub-pan, the screened fractions are discharged directly into a bunker or onto a take-away belt below.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

TAPER-SLOT® Vibratory Screen – Action Vibratory Equipment

Conveyor, Industrial Machinery, Vibrating ConveyorTAPER-SLOT® Vibratory Screen – Action Vibratory Equipment

0 out of 5(0)Battleship Tough Vibratory Finger Screen

The innovative long-stroke TAPER-SLOT® Vibratory Screen is designed to excel in challenging applications that conventional vibratory screens cannot handle. It is ideally suited for non-uniform and difficult-to-screen bulk materials. The combination of long-stroke vibratory action and screen design provides a smooth, continuous material flow and efficient separations.

For stickier applications, including C&D materials, you can now select a SUB-PAN FREE® long-stroke TAPER-SLOT® Screen with classified fractions discharging directly into a bunker or onto a take-away conveyor. The SUB-PAN FREE® option is the ideal choice for sticky applications, eliminating material build-up, wear, and related sub-pan maintenance tasks.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

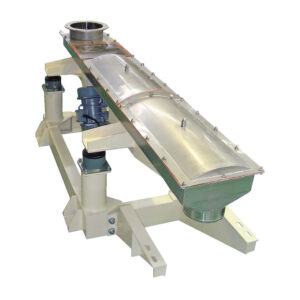

Trough Vibrating Conveyor Vibro Conveyor – URAS TECHNO CO. LTD.

Conveyor, Industrial Machinery, Vibrating ConveyorTrough Vibrating Conveyor Vibro Conveyor – URAS TECHNO CO. LTD.

0 out of 5(0)The Uras Vibrating Conveyors are low-maintainance, provide complete discharge of materials, and prevent spilling and contamination.

The Vibro Conveyor efficiently moves powders and granular materials by applying linear vibration to a trough. The CD Series conveyors use two Uras Vibrators to generate forced vibration, while the CPR Series and CBR Series conveyors use an electric motor driving a crankshaft to create resonant vibration. The trough completely discharges the material that is fed into it, making it easy to clean and maintain. Additionally, a completely closed trough is available as an option, which prevents the spilling and contamination of materials. Furthermore, the Vibro Conveyor can handle materials of any size and temperature.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

VIBRA-SNAP® Flip-Flow Screen – Action Vibratory Equipment

Conveyor, Industrial Machinery, Vibrating ConveyorVIBRA-SNAP® Flip-Flow Screen – Action Vibratory Equipment

0 out of 5(0)Uncompromised Flip-Flow Screening for Extreme Materials

The VIBRA-SNAP® Flip-Flow Screen is an effective alternative to conventional rigid deck screeners for the efficient processing of difficult materials. It is ideally suited for screening moist, sticky, fibrous, wet, and bulk materials with a high percentage of fines or near-size particles. Flexible polyurethane screens tension and relax to generate high material accelerations via ACTION’s patented polyurethane screen mat geometry and connection system. Single- and multi-deck options are available.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

VIBRATION CONVEYOR – Sugiyama Heavy Industrial

0 out of 5(0)Vibration motor vibrates the trough, and the object is transported in synchronized motion by resonance with the cushion spring.

Through vibration, contact between the trough conveying surface and the material is reduced, thus decreasing contamination caused by conveying hot products and abrasion.

Vibratory conveying prevents excessive external force from being applied to the material being conveyed, allowing for the conveying of granules, pellets, etc. without powdering or breakage of grains.

A wide range of options are available, including an intermediate discharge mechanism and a classifying mechanism during conveying.SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

Vibratory Feeders – Action Vibratory Equipment

0 out of 5(0)ACTION offers a wide range of performance-proven vibratory feeders.

Like all ACTION vibratory equipment, each feeder is designed with the appropriate stroke, RPM, and inclination for efficient conveying and metering of bulk materials. Compatible hoppers, gates, screen sections, distribution domes, and other components can be integrated.

SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

VIBRO-CONVEYOR DRYER – Sugiyama Heavy Industrial

0 out of 5(0)Continuous heating and drying of materials while vibratory conveying by introducing hot air into a double structure open-hole trough

Efficient, continuous heating is achievable by fluidizing the material with hot air.

Pulverization of the material and air exhaust can be conducted to remove fine particles.

Punching troughs can be chosen according to the target material.SKU: n/a - Conveyor, Industrial Machinery, Vibrating Conveyor

VIBRO-CONVEYOR FIR DRYER – Sugiyama Heavy Industrial

Conveyor, Industrial Machinery, Vibrating ConveyorVIBRO-CONVEYOR FIR DRYER – Sugiyama Heavy Industrial

0 out of 5(0)Heating elements are mounted in the upper casing, and materials are continuously heated and dried while vibratory conveyance is performed.

Efficient, continuous heating is possible due to the fluidization of materials through vibration. Vibratory conveying prevents excessive external forces from being applied to the material being conveyed, thus enabling the conveying of granules, pellets, etc. without powdering or breakage of grains. The heater can be selected according to the target material.

SKU: n/a

Showing all 21 results

Are you looking for a Vibrating Conveyor product?

When selecting Vibrating Conveyor for your company’s needs, there are several important points to consider during the comparison and evaluation process.

1. Quality and Durability

Prioritize Vibrating Conveyors made from high-quality materials to ensure longevity and reliable performance in your manufacturing environment.

2. Performance and Efficiency

Evaluate the conveyor’s conveying capacity, vibration frequency, and energy efficiency to align with your production needs.

3. Maintenance and Reliability

Consider maintenance needs and the conveyor’s reliability. A reliable system reduces downtime and operational disruptions.

4. Safety Features

Ensure the Vibrating Conveyor includes essential safety features like proper guarding to protect workers from moving parts.

5. Cost and Return on Investment (ROI)

Balance the initial cost of the conveyor with its potential to enhance efficiency, productivity, and cost savings over time.