Drag Chain Conveyor

Showing all 20 results

- Chain Conveyor, Conveyor, Drag Chain Conveyor, Industrial Machinery

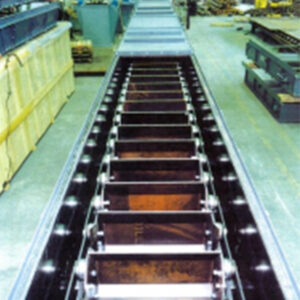

Alba’s standard drag chain conveyors – Alba Manufacturing Inc.

Chain Conveyor, Conveyor, Drag Chain Conveyor, Industrial MachineryAlba’s standard drag chain conveyors – Alba Manufacturing Inc.

up to 4,000 lbs capacity

Drag chain conveyors are composed of heavy-gauge formed chain rails with a welded steel frame, UHMW wear strips, and adjustable heavy-duty structural steel supports, enabling them to withstand the daily rigors of a tough environment. Standard speeds are 30, 45, and 60 feet per minute.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

CDM’s Drag Chain Conveyor – CDM Systems Inc.

Two Types of Drag Chain Conveyors for a Wide Range of Material Handling Industries

Drag chain conveyors are the most effective way to move or elevate bulk material and transfer it from one point to another. The design, layout configurations, service duty rating, size of the drive, and type of chain and flight assembly all play a major role in determining the quality, durability and longevity of any given drag conveyor.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

Chainflow Drag Chain Conveyors – Spiroflow

It economically conveys dry, hot or cold powders and granules, especially fragile materials, a wide variety of chemicals and plastics.

Spiroflow’s Chainflow tubular drag chain conveyor is the latest mechanical conveying solution in our comprehensive range of mechanical conveyors designed for the dry bulk solids and powder processing industry. This hygienic, heavy-duty, totally enclosed, dust-free Chainflow tubular drag conveyor economically transports dry, hot (up to 180°F/82°C) or cold, powders and granules, particularly fragile materials such as cereals, nuts, coffee beans, food ingredients, pet food, animal feed, and a wide variety of chemicals and plastics. Processors can easily convey or batch ingredients with a crevice-free material contact chain and have flexibility in layout options. They effectively convey any number of non-cohesive dry powders and granules.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

CHIPMASTER™ DRAG CHAIN CONVEYOR SYSTEM – MC3 Manufacturing Inc.

Conveyor, Drag Chain Conveyor, Industrial MachineryCHIPMASTER™ DRAG CHAIN CONVEYOR SYSTEM – MC3 Manufacturing Inc.

An Economical Solution for Fine Chip Removal and Filtering Coolant!

MC3 drag-out conveyors offer an economical solution for filtering and transporting fine chips. For wet chips or turnings, drag chain conveyor systems can provide efficient coolant filtration. Specifically designed for smaller scrap and contaminants, you can be sure that your machines are supplied with the purest coolant possible. The bottom of the chamber is resistant to scratches and other abrasions, helping your machinery remain in good condition as it performs its task.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

Drag chain conveyor MT – ROBOT FOOD TECHNOLOGIES Germany GmbH

Conveyor, Drag Chain Conveyor, Industrial MachineryDrag chain conveyor MT – ROBOT FOOD TECHNOLOGIES Germany GmbH

Drag chain conveyor MT with several filling stations and dressing dosing device

The drag chain conveyor MT is a cost-effective transport system that is characterized by its flexible applications, easy operation, and simple cleaning. Thanks to its compact design, the drag chain conveyor MT is as space-saving as a rotary machine, while offering all the advantages of a modular linear line.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

Dynaflow Drag Chain Conveyors – Spiroflow

The Dynaflow Tubular Drag Chain Conveyor is a mechanical drag conveyor system operating within the confines of a pipe.

Spiroflow’s Dynaflow® tubular drag conveyors are structural mechanical drag chain conveyors operating within the confines of a pipe. In this conveyor, discs connected by articulated metal links (chains) move material within the pipe, making it ideal for ultra-heavy-duty applications. The discs are made from a variety of materials, including steel and cast iron. Dynaflow drag chain conveyors are suitable for applications with temperatures up to 420°F / 216°C.

SKU: n/a - Chain Conveyor, Conveyor, Drag Chain Conveyor, Industrial Machinery

EN-MASSE DRAG CHAIN CONVEYOR – Norstar

- Chain Conveyor, Conveyor, Drag Chain Conveyor, Industrial Machinery

INCLINE DRAG CHAIN CONVEYORS – Norstar

Chain Conveyor, Conveyor, Drag Chain Conveyor, Industrial MachineryINCLINE DRAG CHAIN CONVEYORS – Norstar

CONVEYING AT AGGRESSIVE INCLINES CAN CAUSE LOSS OF CAPACITY.

Loss of throughput results in inefficiency and wasted time and money. Incline drag conveyors help you get the job done correctly.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

L Slat STE80 – SANEI Co.Ltd.

It doesn’t bite in, it doesn’t stop.

One of the essential tasks in metal processing is to discard scrap from lathes, presses, and other processing machines. We have designed a conveyor to make this task more efficient.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

L-slat STE50 – SANEI Co.Ltd.

It doesn’t bite in, it doesn’t stop.

One of the essential tasks in metal processing is to discard scrap from lathes, presses, and other processing machines. We have designed a conveyor to make this task more efficient.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

Metso’s Drag chain conveyors – Metso

Efficiency and capacity with a competitive edge

Drag chain conveyors are designed with safety, efficiency, reliability, and exceptional performance in mind. Their airtight construction keeps dust contained and material free from contamination up to a 35-degree incline.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

ODM – Drag chain conveyors TKF/KKF – DI MATTEO Group.

Conveyor, Drag Chain Conveyor, Industrial MachineryODM – Drag chain conveyors TKF/KKF – DI MATTEO Group.

Drag chain conveyor is counted among the most tested and important kinds of transport for a wide variety of bulk materials.

Our drag chain conveyors are ideal for continuous horizontal or steeply inclined transportation. In addition to the usual transport requirements, they can also be used as discharge conveyors and distribution conveyors with multiple inlets and outlets. The bulk materials are transported cleanly and securely in a sealed trough by a continuous conveyor chain with actuators.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

TRA – Drag chain conveyor with double round steel chain – Advanced Conveyor Technology

Conveyor, Drag Chain Conveyor, Industrial MachineryTRA – Drag chain conveyor with double round steel chain – Advanced Conveyor Technology

helps to reduce the height

Two chains drive the material in drag chain conveyors; these chains are composed of round steel strands connected by shackles, which also attach the material scrapers situated between the two rows of chains.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

TRC – Submerged drag chain conveyor – Advanced Conveyor Technology

- Conveyor, Drag Chain Conveyor, Industrial Machinery

TRD – Drag chain conveyor with double chain – Advanced Conveyor Technology

Conveyor, Drag Chain Conveyor, Industrial MachineryTRD – Drag chain conveyor with double chain – Advanced Conveyor Technology

mount traditional spring-type or hydraulic chain tensioning systems

Drag chain conveyors are equipped with two drop-forged chains that drive the material; these chains are made of wear-resistant steel and feature side connecting ribs for linking the scrapers located between the two rows of chains.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

TRL – Cleaning drag chain conveyor with linear axis – Advanced Conveyor Technology

- Conveyor, Drag Chain Conveyor, Industrial Machinery

TRLC – Cleaning drag chain conveyor with C-shaped curved axis – Advanced Conveyor Technology

Conveyor, Drag Chain Conveyor, Industrial MachineryTRLC – Cleaning drag chain conveyor with C-shaped curved axis – Advanced Conveyor Technology

Suitable for hauling fine-grained material at relatively low flow rates.

Drag chains conveyors for recovering dust that spills beneath the ends of main conveyors and discharging them into the latter.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

TRP – Scraper-paddle conveyor – Advanced Conveyor Technology

Conveyor, Drag Chain Conveyor, Industrial MachineryTRP – Scraper-paddle conveyor – Advanced Conveyor Technology

The machine can also haul lumps of material, and high flow rates can be achieved.

A special drag chain conveyor is equipped with two drop-forged chains with pins, bushings, and guide wheels, which roll on lateral tracks and support the paddles that shift the material.

SKU: n/a - Conveyor, Drag Chain Conveyor, Industrial Machinery

TRS – Drag chain conveyor with single drop forged chain – Advanced Conveyor Technology

Conveyor, Drag Chain Conveyor, Industrial MachineryTRS – Drag chain conveyor with single drop forged chain – Advanced Conveyor Technology

counter the friction of the material along the side walls.

A single drop-forged chain drives the material along drag chain conveyors, with material scrapers welded to each side of the wear-resistant steel chain.

SKU: n/a

Are you looking for a Drag Chain Conveyor product?

When selecting Drag Chain Conveyor for your company’s needs, there are several important points to consider during the comparison and evaluation process.

1. Performance and Efficiency

Evaluate the conveyor’s conveying capacity, speed, and energy efficiency to align with your production requirements.

2. Maintenance and Reliability

Consider maintenance needs and the conveyor’s reliability. A reliable system reduces downtime and operational disruptions.

3. Safety Features

Ensure the Drag Chain Conveyor includes essential safety features like emergency stops and proper guarding to protect workers.

4. Cost and Return on Investment (ROI)

Balance the initial cost of the conveyor with its potential to enhance efficiency, productivity, and cost savings over time.