Fruit & Vegetable Processing Machines

Showing 1–24 of 88 results

- Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Fruit Peeling Machine FAP-1001 – Astra Inc.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesFruit Peeling Machine FAP-1001 – Astra Inc.

Able to peel +20 kinds of fruits/ vegetables / High quality peeling in triple speed / Great durability / Wonky fruits/ vegetables are no problem / A better peel, a longer shelf life

FAP-1001, the “Peel-A-Ton XL” is the powerful and high-speed version of KA-700H for heavy users. Automatic ejector makes the work speed three times faster. Easy to use and clean, allowing uncomplicated training for any level of employee.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Fruit Peeling Machine KA-700H – Astra Inc.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesFruit Peeling Machine KA-700H – Astra Inc.

Able to peel +20 kinds of fruits/ vegetables / Wonky fruits/ vegetables are no problem / A better peel, a longer shelf life / Compact, space-saving design

Compact design, adjustable and extremely efficient, the award winning KA-700H, the “Peel-A-Ton” is a labor-saving device that peels with the precision first-class chefs’ dream of. Easy to operate and easy to clean.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Fruit Peeling Machine KA-750PM – Astra Inc.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesFruit Peeling Machine KA-750PM – Astra Inc.

The only tabletop electric peeler of pineapples, melons, mangoes, and pumpkins / Highest yield rate of any peeler in its class / Wonky fruits/ vegetables are no problem / A better peel, a longer shelf life / Three types available to meet your needs

Can peel: Pineapple, Mango and Melon “Pineapplator” KA-750PM uses its large steel blade to peel fruits vertically. With minimal edible flesh removed in the process, product yield is increased +20% than traditional hand peeling.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Fruit Peeling Machine KA-851 – Astra Inc.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesFruit Peeling Machine KA-851 – Astra Inc.

The only tabletop electric peeler of pineapples, melons, mangoes, and pumpkins / Highest yield rate of any peeler in its class / Wonky fruits/ vegetables are no problem / A better peel, a longer shelf life / Three types available to meet your needs

Can peel: Pineapple, Mango, Melon, and Pumpkin

KA-851 is the pineapple peeling machine which gathers the peeled skin directly into a dust box. Recommended for the small-mid range processors, e.g. supermarket backyards.SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Mango Peeling Machine KA-730M – Astra Inc.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesMango Peeling Machine KA-730M – Astra Inc.

The only tabletop electric peeler of pineapples, melons, mangoes, and pumpkins / Highest yield rate of any peeler in its class / Wonky fruits/ vegetables are no problem / A better peel, a longer shelf life / Three types available to meet your needs

Can peel: Choose one from Mango/ Melon

KA-730M is the affordable priced, smaller version of KA-750PM, specially manufactured for mangoes. Possible to peel all small to large mangoes with the same speed of KA-750PM. Recommended if you don’t peel pineapples.SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Pineapple Peeling Machine KA-720P – Astra Inc.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesPineapple Peeling Machine KA-720P – Astra Inc.

The only tabletop electric peeler of pineapples, melons, mangoes, and pumpkins / Highest yield rate of any peeler in its class / Wonky fruits/ vegetables are no problem / A better peel, a longer shelf life / Three types available to meet your needs

Can peel: Choose one from Pineapple/ Pumpkin

KA-720P is the affordable priced, smaller version of KA-750PM for light users. Recommended for users who peel pineapples in smaller quantity.SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Air Pine Pillar (PAT.&PAT.P) – HIRANO WORKS CO. LTD.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAir Pine Pillar (PAT.&PAT.P) – HIRANO WORKS CO. LTD.

When it comes to pineapple peeling machines, HIRANO!This medium-sized, air-powered, automatic machine is easy and safe to operate.It can peel and split a large amount of pineapple without any force.

High-power type that can separate a single pineapple into hole-pulling and core-pulling segments with the push of a button. It contributes to dramatic productivity improvement.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Air Radish Carrot Peeling Machine Single Type (PAT.P) – HIRANO WORKS CO. LTD.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAir Radish Carrot Peeling Machine Single Type (PAT.P) – HIRANO WORKS CO. LTD.

Air-powered peeling of radishes and carrots made easy!

This high power type peels troublesome radishes and carrots at the push of a button. It contributes to dramatic productivity improvement. Dual type for peeling two carrots at the same time and single type for peeling one carrot are available.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

AMS 220 pineapple and melon peeling machine – KRONEN GmbH

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAMS 220 pineapple and melon peeling machine – KRONEN GmbH

Perfect, contour-independent peeling of pineapple, melons of all kinds and squashes and pumpkins with a smooth surface with exceptional peeling quality

Your benefits

Exceptional peeling quality due to a specially developed contour guiding system (contour-independent)

The adjustable peeling thickness from 1.5 to 13 mm enables optimal peeling results

The intelligent peeling system guarantees an optimal product yield compared to manual peeling

All required tools and accessories hang within easy reach on a tool bar integrated directly on the machine

Flexible and versatile peeling options even for small watermelons, several types of papaya and breadfruitSKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

AP15 pineapple, melon, and papaya Peeler & Corer – ABL S.r.l.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAP15 pineapple, melon, and papaya Peeler & Corer – ABL S.r.l.

The AP15 Industrial Fruit Peeler and Corer can be used to process pineapple, melon, and papaya.

The AP15 Industrial Fruit Peeler and Corer can be used to process pineapple, melon, and papaya. The AP15 Industrial Fruit Peeler and Corer, with capacity of 12/13 fruits per minute. This machinery for the processing of pineapples, melons and papaya is extremely simple to use and offers high reliability. In combination with the GTF it provides chunked or sliced fruit. The peeling depth is adjustable according to the fruit being processed, turning a simple knob in a few seconds and without having to stop the machine. Top and Tail cutting device included.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

AS 2 apple peeling and slicing machine – KRONEN GmbH

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAS 2 apple peeling and slicing machine – KRONEN GmbH

A handy tabletop device for semi-automatic apple processing: proven for decades and ideally suitable for peeling, coring, wedging and slicing apples

The AS 2 peeling, slicing and coring machine for apples is a very compact, easy-to-use multifunctional tabletop device used in the high-care area of fruit processing. It is loaded manually, and up to three apples can be processed at the same time, meaning that up to 600 apples, equivalent to approximately 90 kg (at 150 g/apple), can be processed per hour. If additional apple slices are to be cut, the AS 4 or the AS 6 is a good option.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

AS 4 apple peeling and slicing machine – KRONEN GmbH

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAS 4 apple peeling and slicing machine – KRONEN GmbH

A handy tabletop device for semi-automatic apple processing: proven for decades and perfect for peeling, coring, wedging and slicing apples

The AS 4 peeling, slicing and coring machine for apples is a very compact, easy-to-use multifunctional tabletop device used in the high-care area of fruit processing. It is loaded manually, and up to three apples can be processed at the same time, meaning that up to 600 apples, equivalent to approximately 90 kg (at 150 g/apple), can be processed per hour.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

AS 6 apple peeling and slicing machine – KRONEN GmbH

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAS 6 apple peeling and slicing machine – KRONEN GmbH

The multifunctional machine is optimized for peeling, coring, wedging and slicing apples – quickly, safely and for high capacities.

The AS 6 is a peeling, slicing and coring machine for apples used in the high-care sector of industrial processing. The apples only need to be inserted and are then skewered and processed completely automatically. The machine can process three apples at the same time. Therefore, a capacity of up to 900 apples per hour is achieved, which is equivalent to approximately 135 kg per hour (at 150 g/apple).

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing Machines

Auto Pine Cutter – HIRANO WORKS CO. LTD.

Food & Beverage Machinery, Fruit & Vegetable Peeling Machine, Fruit & Vegetable Processing MachinesAuto Pine Cutter – HIRANO WORKS CO. LTD.

When it comes to pineapple peeling machines, HIRANO!Achievements and technologies cultivated over 40 years of manual pineapple peeler experience are now available in a fully automatic machine.High-speed processing of 720 pineapples per hour.Many major supermarkets and cut fruit factories nationwide have installed this machine!

High speed of 5 seconds per ball!

Feel the sharpness that only a blade manufacturer can provide!

Anyone can handle it easily!

Contributes to labor saving and productivity improvement

Reliable maintenance by a domestic manufacturer

No need to cut both ends, contributing to labor savingSKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines

Automated Matcha Processing Line – Tea Processing Machines – Hattori Seisakusho Co.LTD.

Food & Beverage Machinery, Fruit & Vegetable Processing MachinesAutomated Matcha Processing Line – Tea Processing Machines – Hattori Seisakusho Co.LTD.

Full Automated Matcha Processing Line.

After drying process, this crushes Tea leaves and removes stalks and leaf vein for making high quality Matcha.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable Cutter

BURDOCK CUTTER / MODEL BS – EMURA FOOD MACHINE CO.LTD.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable CutterBURDOCK CUTTER / MODEL BS – EMURA FOOD MACHINE CO.LTD.

BS can cut burdock into shreds, diagonal slices, sasagaki shape and sasagiri shape.Cuts products in the same way as handmade cutting.

Depending on processing amount, functions and blades can be upgraded.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable Cutter

CABBAGE CORER AND DIVIDER / MODEL CW-500 – EMURA FOOD MACHINE CO.LTD.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable CutterCABBAGE CORER AND DIVIDER / MODEL CW-500 – EMURA FOOD MACHINE CO.LTD.

Cores and divides cabbage in one machine.

Equally divides materials regardless of their sizes.

Also, it adjusts the coring depth by sizes, so neither too much nor neither too little.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable Cutter

Cabbage Cutting Machine – DRC-80 JUMBO CABBETSU – Happy Japan Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable CutterCabbage Cutting Machine – DRC-80 JUMBO CABBETSU – Happy Japan Co.

High speed cabbage slicer

There is high speed grade-up cabbage slicer of model RCS-71. Which is equipped with a drum that can slice 4~5 heads of cabbages per each time. The cutting blade is 170mmФ and durable for long hour use.

Watch Video : https://youtu.be/j6xQcyi2pBM

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable Cutter

Cabbage Cutting Machine – RCS-71 CABBETSU – Happy Japan Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Vegetable CutterCabbage Cutting Machine – RCS-71 CABBETSU – Happy Japan Co.

Slices cleanly under the own weight of the cabbage

There is no need to press on the cabbage while slicing.

The turning drum and round blade is designed so that the cabbage is self-feeding and slices freely.

Cutting time for 13 to 15 head cabbage is 30 minute.

Cut cabbage in half and remove the core and feed into drum.

Cleaning is simple and easy.Watch Video : https://youtu.be/ULJmubf3cg0

“Example of use”

1. cabbage slices

Cut cabbage in half.

Remove the cabbage core in advance.

Turn on the machine with the cross section face down, and the machine will do the rest.

The thickness can be adjusted steplessly. (0.3 to 5.0 mm) 2.Cutting tomatoes

Tomatoes can also be cut using the optional onion attachment.*When using thin slices, the seeds will come off the pulp, so please use thick slices.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

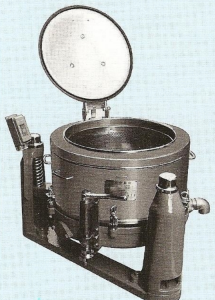

Centrifuge DT-1 Top discharge type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-1 Top discharge type – Daiei Seisakusho Co.

Motor is a high-torque motor specially designed for centrifuges

Applications

Dehydration of various vegetables, pickles, confectionery industry, ham, sausage, fish meat, livestock, tsukudani, seafood processing, dehydration of textiles, deoiling of cutting layersSKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge DT-2 Popular type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-2 Popular type – Daiei Seisakusho Co.

Noiseless dehydration.

Applications

Dehydration of cabbage and onions for dumplings and shao mai, dehydration and drying of vegetables, pickles, confectionery industry, ham, sausage, fish meat, livestock, tsukudani, fishery industry, dehydration of textiles, deoiling of cuttingSKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge DT-2B double basket type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-2B double basket type – Daiei Seisakusho Co.

Often used for de-oil recovery of tempura and dregs, and dehydration of vegetable noodles after cutting

Applications

Dehydration of tempura, tempura dregs, dehydration of prepared food period. Dehydration of cabbage and onion, dehydration of kitchen and residue.SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge DT-K with scraping device Bottom discharge type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-K with scraping device Bottom discharge type – Daiei Seisakusho Co.

Ideal for labor-saving dehydration work

Applications

Chemical industry: various metal powder crystals, calcium chloride, sodium, lime, plastics, and other chemical products

Food industry: salt production, sugar starch production, brewing, processed water products, livestock products, processed vegetable products, confectionery

Pollution: plating industry, general factories, fisheries, livestock wastewater sludge treatmentSKU: n/a

Are you looking for a fruit and vegetable processing machine product?

When selecting fruit and vegetable processing machines for your company’s needs, there are several important points to consider during the comparison and evaluation process.Common Comparison Points for Any Fruit & Vegetable Processing Machine

1. Processing Capacity

Assess the processing capacity of the machine, which refers to the quantity of fruits and vegetables it can handle within a given time. Consider your production requirements and choose a machine that can handle the desired volume efficiently.

2. Processing Efficiency

Evaluate the processing efficiency of the machine. Look for machines that can process fruits and vegetables quickly and effectively, minimizing waste and maximizing output. Efficient processing ensures productivity and cost-effectiveness.

3. Versatility

Assess the versatility of the processing machine. Look for machines that can handle a wide range of fruits and vegetables, including different sizes, shapes, and textures. Consider the availability of interchangeable or adjustable components to accommodate various processing needs.

4. Quality of Output

Consider the quality of the processed fruits and vegetables produced by the machine. Look for machines that can maintain the integrity, appearance, and nutritional value of the produce during processing. Features such as gentle handling, precise cutting, and effective sorting contribute to high-quality output.

5. Automation and Control

Evaluate the level of automation and control features of the processing machine. Look for machines with advanced automation capabilities, user-friendly interfaces, and adjustable settings to achieve desired processing results. Automation can enhance productivity and consistency.

6. Cleaning and Maintenance

Consider the ease of cleaning and maintenance features of the processing machine.