Packing Equipment

Showing 1–24 of 34 results

- Food & Beverage Machinery, Packing Equipment

FJ-500XL – VACUUM PACKAGING MACHINE – Nantsune Inc.

Long term storage and packing with the same quantity, quality and taste, and even liquid.

LOW PRICE

●100V power supply specification!

●Comes with memory function!

●The software feature ensures that the product and the bag are undamaged and vacuumed.

●Easy and simple operation panel!SKU: n/a - Food & Beverage Machinery, Packing Equipment

Impulse AZ Sealer 200W/300W – Asahi Industry Co.Ltd.

Simply apply light pressure to seal tightly.

Strong sealing / Impulse sealing / Compact body

Simply apply light pressure to the table with both hands to seal tightly.Ideal for sealing bags that provide protection from light,moisture, discoloration, loss of fragrance and is also perfect for use with silica gel packets.

It is possible to seal up to 5 mil thickness aluminum gadget bags.Dual-heating element model

Heating elements are mounted on both upper and lower sides.

It is possible to seal aluminum metalized film bags with four layers overlapping firmly.

*Perfect for metallic bag sealing to keep loose-leaf tea and coffee beans fresh by preserving fragrance and protecting from light.– Made in Japan –

SKU: n/a - Food & Beverage Machinery, Packing Equipment

PEONY Hand wrapper B-45PN/B-450JP – Asahi Industry Co.Ltd.

Food & Beverage Machinery, Packing EquipmentPEONY Hand wrapper B-45PN/B-450JP – Asahi Industry Co.Ltd.

High energy efficiency model which is assembled with easy changeable parts.

・High quality model, known as the number one product in the Japanese market.

・Compatible with plastic wraps, PVC wraps and other stretch films by various manufacturers.

・Supports maximum film width of 450 mm.

・ Features sturdy, durable and corrosion resistant zinc aluminum coated steel plate.

・ An energy-saving product that offers accurate temperature adjustment with built-in electronic thermostat (the hot plate will not be engaged when the temperature is set to 0).

・Features a hot plate that is finished in a special embossed coating, making it easy to keep the product clean and hygienic!

・Very popular product for food plating and packaging at various convenience stores, food processing factories and so on.

・The renowned hand wrapper has a long history since its launch in 1968.”SKU: n/a - Food & Beverage Machinery, Packing Equipment

PEONY Hand wrapper U-45PN/U-450JP – Asahi Industry Co.Ltd.

Food & Beverage Machinery, Packing EquipmentPEONY Hand wrapper U-45PN/U-450JP – Asahi Industry Co.Ltd.

High energy efficiency model which is assembled with easy changeable parts.

・High quality model, known as the number one product in the Japanese market.

・Compatible with plastic wraps, PVC wraps and other stretch films by various manufacturers.

・Supports maximum film width of 450 mm.

・ Features sturdy, durable and corrosion resistant zinc aluminum coated steel plate.

・ An energy-saving product that offers accurate temperature adjustment with built-in electronic thermostat (the hot plate will not be engaged when the temperature is set to 0).

・Features a hot plate that is finished in a special embossed coating, making it easy to keep the product clean and hygienic!

・A tremendously popular product for food plating & packaging at various convenience stores and food processing factories.

・The renowned hand wrapper has a long history since its launch in 1968.SKU: n/a - Food & Beverage Machinery, Packing Equipment

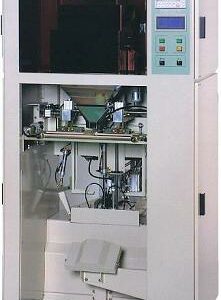

rice packing machine- AXIS KP-10M・KP15A – Chuubu Aitec CO.LTD.

Food & Beverage Machinery, Packing Equipmentrice packing machine- AXIS KP-10M・KP15A – Chuubu Aitec CO.LTD.

Easy to operate, space-saving, highly reliable, adaptable to single bags, fully automatic weighing and integrated packaging machine.

Set the bag, align the bag-taking suction cups with the bag and change the mould to complete the preparation. All that is left to do is to press the operation button.

Fully automatic weighing and packaging machine that automatically takes, opens, weighs, feeds, seals and bottoms up the set bags one by one.

The weighing machine is of the cut-gate type, suitable for weighing rice grains, granular and granular products.

Three-stage control realises high speed.

Semi-systems etc. (conveyor weighers, mass weighers etc. will be considered on request).

Full range of options.

Highly reliable, used in a wide variety of applications since production started in 1992.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- CORRECT KP10Z – Chuubu Aitec CO.LTD.

Food & Beverage Machinery, Packing Equipmentrice packing machine- CORRECT KP10Z – Chuubu Aitec CO.LTD.

Easy-to-operate, hassle-free, space-saving, highly reliable, fully automatic integrated weighing and wrapping machine.

Set the bag, align the bag-taking suction cups with the bag and change the mould to complete the preparation. All that is left to do is to press the operation button.

Fully automatic weighing and packaging machine that automatically takes, opens, weighs, feeds, seals and bottoms up the set bags one by one.

The weighing machine is of the cut-gate type, suitable for weighing rice grains, granular and granular products.

Equipped with two 3-stage controls for high speed weighing.

Semi-systems etc. (conveyor weighers, mass weighers etc. will be considered on request).

Full range of options.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- DSR-110 – NOMURA CORPORATION

Automatic weighing and packaging machine with simple mechanism and low price!

This is an automatic weighing and packaging machine with the three key features of low price, compactness, and reliability.

Utilizing our accumulated know-how, we have achieved simplicity and low cost by consolidating functions while ensuring stability.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- FLS-66 – NOMURA CORPORATION

6-position rotary type is adopted! Even faster operation!

The machine is designed to provide ample space, and a print image inspection device can be installed in the bag-making section, and a freshness preservation device (gas filling and degassing) can be installed in the optional rotary section.

The expandable design makes it easy to retrofit after delivery, contributing to the creation of “valuable products” that meet diversifying needs.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- JUSPER JP-10Z – Chuubu Aitec CO.LTD.

Food & Beverage Machinery, Packing Equipmentrice packing machine- JUSPER JP-10Z – Chuubu Aitec CO.LTD.

Fully automatic weighing and packaging machine with easy operation and speedy packaging of single bags and roll bags.

The machine is ready when the bag is loaded (for single bags: align the bag-taking suction cups with the bag) and the mould is changed. All that remains is to press the start button.

High-performance, fully automatic weighing and packaging machine for both single bags and roll bags in one machine.

The weighing machine is of the cut-gate type, suitable for weighing rice grains, granular and granular products.

Equipped with two 3-stage controls for high speed.

250 recipes can be registered, and with the optional barcode mould changer, the mould can be easily changed using a barcode.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- JUSTEEN KR-01A – Chuubu Aitec CO.LTD.

Food & Beverage Machinery, Packing Equipmentrice packing machine- JUSTEEN KR-01A – Chuubu Aitec CO.LTD.

Just amazing! Low-cost, easy-to-operate, space-saving, highly reliable, fully automatic integrated weighing and wrapping machine.

Set the bag, align the bag-taking suction cups with the bag and change the mould to complete the preparation. All that is left to do is to press the operation button.

Fully automatic weighing and packaging machine that automatically takes, opens, weighs, feeds, seals and bottoms up the set bags one by one.

The weighing machine is of the cut-gate type, suitable for weighing rice grains, granular and granular products.

Three-stage control realises high speed.

Fully automatic weighing and packaging machine with low price and high reliability.

Wide range of options such as semi-systems.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- JUSTEEN KRC-01 – Chuubu Aitec CO.LTD.

Food & Beverage Machinery, Packing Equipmentrice packing machine- JUSTEEN KRC-01 – Chuubu Aitec CO.LTD.

Stand-up pack with zip, easy operation, high reliability, adaptable to single bags, fully automatic weighing and integrated packaging machine.

Set the bag, align the bag-taking suction cups with the bag and change the mould to complete the preparation. All that is left to do is press the operation button.

Compatible with stand-up packs with zip, and the zip can be opened and closed. Of course, normal single bags can also be used.

Fully automatic weighing and packaging machine that automatically takes the set bags one by one, opens, weighs, feeds, seals, closes the zip and bottoms up.

The weighing machine uses a combination of a cut gate and an electromagnetic feeder, with small feeds being carried out by the electromagnetic feeder for improved weighing accuracy and stability.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- JUSTEEN・R JR-01 – Chuubu Aitec CO.LTD.

Food & Beverage Machinery, Packing Equipmentrice packing machine- JUSTEEN・R JR-01 – Chuubu Aitec CO.LTD.

Fully automatic weighing and packaging machine with simple, hassle-free operation, space saving and high reliability, for both single bags and roll bags.

The machine is ready when the bag is loaded (for single bags: align the bag-taking suction cups with the bag) and the mould is changed. All that remains is to press the start button.

High-performance, fully automatic weighing and packaging machine for both single bags and roll bags in one machine.

The weighing machine is of the cut-gate type, suitable for weighing rice grains, granular and granular products.

Three-stage control ensures high speed.

The optional barcode change-over device enables easy change-over by barcode.

Space-saving fully automatic weighing and packaging machine for both single bags and roll bags.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- NKR-01A – NOMURA CORPORATION

Simple, compact, and attractive bag-feeding automatic weighing and packaging machine

One-touch changeover of the drop-off for no-rinse rice, germ-free rice, and regular milled rice is easy to operate.

SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- NRP-6 – NOMURA CORPORATION

The latest model in pursuit of multifunctionality and compactness! Stand-up pack weighing and packaging machine with zipper

This is a stand-up pack weighing and packaging machine with zipper that is equipped with a 6-position rotary wrapping machine and a newly developed thin-type double-weighing machine.

The machine meets all packaging needs, including gas filling, multi-functionality, high speed, compactness, easy operation, safety, and hygiene.SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- NX-180R – NOMURA CORPORATION

A quick packer that meets the needs of productivity, diversity, and speed!

Inheriting the philosophy of the Intelligent Series, this weighing and packaging machine analyzes the functions required for rice packaging and pursues further speed, ease of use, and compactness. Advanced technology has been utilized to achieve even greater ease of use and higher speed.

SKU: n/a - Food & Beverage Machinery, Packing Equipment

rice packing machine- QUICKS AQ-110・AQ-115 – Chuubu Aitec CO.LTD.

Food & Beverage Machinery, Packing Equipmentrice packing machine- QUICKS AQ-110・AQ-115 – Chuubu Aitec CO.LTD.

Automatic bag feeding and wrapping machines that are clean, quick and easy for everyone.

Set the bag, align the bag-taking suction cups with the bag and change the mould to complete the preparation. All that is left to do is to press the operation button.

Automatic bag feeder that automatically picks up, opens, fills, seals and discharges the set bags one by one.

Can be docked with weighing machines from other manufacturers.

Compact design saves space in the factory.SKU: n/a

Are you looking for a packing equipment product?

When selecting packing equipment for your company’s needs, there are several important points to consider during the comparison and evaluation process.Common Comparison Points for Any Packing Equipment

1. Packaging Speed and Efficiency

Assess the packaging speed and efficiency of the equipment. Consider factors such as the number of packages per minute, the automation level, and the ease of integrating the equipment into your existing production line. High-speed and efficient packing equipment can enhance productivity and meet your desired packaging volumes.

2. Packaging Accuracy and Consistency

Evaluate the equipment’s ability to achieve accurate and consistent packaging results. Look for features such as precise dosing mechanisms, reliable sealing capabilities, and consistent package quality control. Accurate and consistent packaging ensures product integrity and customer satisfaction.

3. Packaging Flexibility

Consider the equipment’s flexibility in handling various packaging materials, sizes, and formats. Look for adjustable settings, quick changeover features, and compatibility with different packaging types (e.g., bags, boxes, bottles). Flexible packing equipment enables you to accommodate different product variations and adapt to changing market demands.

4. Product Compatibility and Protection

Assess how well the equipment can handle your specific products. Consider factors such as product fragility, sensitivity to environmental factors (e.g., moisture, light), and the need for specialized packaging (e.g., vacuum sealing, modified atmosphere packaging). The equipment should protect the product’s quality, freshness, and shelf life throughout the packaging process.

5. Equipment Footprint and Layout

Evaluate the equipment’s footprint and its impact on your production floor layout. Consider space requirements, access for maintenance and cleaning, and compatibility with your existing infrastructure. Optimize the layout to ensure efficient material flow and minimize production disruptions.

6. Operational Ease and User Interface

Consider the ease of operation and user-friendly interface of the equipment. Look for intuitive controls, clear display panels, and comprehensive instructions. Equipment with user-friendly features simplifies operator training, reduces the potential for errors, and improves overall operational efficiency.

Specific Comparison Points for Packing Equipment

1. Packaging Material Compatibility

Evaluate how well the equipment handles the specific packaging materials you use. Consider factors such as film types, thicknesses, and compatibility with eco-friendly or recyclable materials. The equipment should be able to handle your preferred packaging materials effectively and without compromising quality.

2. Packaging Waste Reduction

Assess the equipment’s ability to minimize packaging waste. Look for features such as precise material dosing, efficient film utilization, and waste reduction mechanisms (e.g., trim removal systems). Minimizing packaging waste aligns with sustainability goals and reduces production costs.

3. Safety Features

Prioritize safety features in the equipment. Look for features such as emergency stop buttons, safety sensors, and guarding mechanisms. Safety considerations should include protecting operators from potential hazards during equipment operation, maintenance, and troubleshooting.

4. Maintenance and Serviceability

Evaluate the ease of maintenance and serviceability of the equipment. Consider features such as accessibility to critical components, ease of cleaning, and availability of spare parts. Equipment with straightforward maintenance procedures and reliable support from the manufacturer can minimize downtime and ensure continuous operation.

5. Integration with Traceability Systems

If traceability is crucial for your products, consider the equipment’s integration capabilities with traceability systems such as barcode scanners or RFID technology. Traceability systems help monitor product flow, track batches, and comply with regulatory requirements.

6. Supplier Support

Consider the reputation and support provided by the equipment supplier. Look for manufacturers with a track record of delivering reliable equipment and offering responsive customer support. Good supplier support ensures timely assistance, training, and access to spare parts and technical expertise.

It is important to conduct thorough research, review customer testimonials, and consult with industry experts or equipment manufacturers directly to choose the right packing equipment for your specific needs.