Sorting Equipment

Showing 1–24 of 183 results

- Food & Beverage Machinery, Sorting Equipment

Absolute Color / GR Series – ACTIVE CO.LTD.

Quality Control Sorting Machine High Definition. Equipped with CMOS Line Scan Camera.

Absolute Color

Quality Control Sorting MachineAbsolute Color – GR

Quality Control Sorting Machine with foreign substance reject function loadingSKU: n/a - Food & Beverage Machinery, Sorting Conveyor, Sorting Equipment

Air jet method – sorting conveyor – SYSTEM SQUARE INC.

Food & Beverage Machinery, Sorting Conveyor, Sorting EquipmentAir jet method – sorting conveyor – SYSTEM SQUARE INC.

Air blows defective products off the conveyor.

Suitable for lightweight products. The nozzle can be set on both sides

The nozzles can be set on both sides to distribute the product in three directions.SKU: n/a - Food & Beverage Machinery, Sorting Equipment

All stainless steel strainer – Tokyo Kikuchi Shokai Co.

Since the parts that come in contact with the raw materials are made of stainless steel, they can be used without problems even when the raw materials contain salt.

The base is also made of stainless steel, allowing for long-term use and eliminating the risk of rust and other corrosion.

SKU: n/a - Food & Beverage Machinery, Sorting Equipment

AMD® RG MAX NIR Rice Color Sorter Machine – Anhui Zhongke Optic-electronic Color Sorter Machiner

Food & Beverage Machinery, Sorting EquipmentAMD® RG MAX NIR Rice Color Sorter Machine – Anhui Zhongke Optic-electronic Color Sorter Machiner

In addition to inheriting the excellent performance of RG+, the latest AMD MAX series rice color sorter uses a new algorithm and optimized optical path to achieve the superior effect of sorting yellow rice without chalky rice, and sorting chalky rice without yellow rice.

AMD rice color sorter machine, intelligent RGB CCD optical rice sorting machine, flexible with multiple color sorting plans. Sort yellow, chalky, paddy and foreign materials out, available for long-grain,round-grain, basmati, parboiled and all other kinds of rice applications. AMD has already developed more than 10 different types of rice color sorters which are designed for rice sorting. High speed with remote control AI system,the sorting precision is closed to 99.999%.

SKU: n/a - Apple Sorting Machine, Food & Beverage Machinery, Sorting Equipment

APPLE GRADING & SORTING MACHINES – Futura S.r.l.

Apple Sorting Machine, Food & Beverage Machinery, Sorting EquipmentAPPLE GRADING & SORTING MACHINES – Futura S.r.l.

Apple Sorting, Grading, Packing and Processing Machines

Apples are amongst the most delicate fruits. In fact, they bruise quite easily. For this reason, FUTURA takes great care of the whole apple sorting process, so as to prevent any kind of damage to your fruits.

SKU: n/a - Apple Sorting Machine, Food & Beverage Machinery, Sorting Equipment

Apple Grading Machine – Viraj Machinery

Apple Sorting Machine, Food & Beverage Machinery, Sorting EquipmentApple Grading Machine – Viraj Machinery

Classify apples based on its outer skin as well as its inner diffects if any like : soft , cuts and also able to find apple diseases like cochineal etc.

Less manpower required to monitor the complete process.

SKU: n/a - Apple Sorting Machine, Food & Beverage Machinery, Sorting Equipment

Apple Grading Machine [KM-300, Single Lane] – Viraj Machinery

Apple Sorting Machine, Food & Beverage Machinery, Sorting EquipmentApple Grading Machine [KM-300, Single Lane] – Viraj Machinery

Classify apples based on its outer skin as well as its inner diffects if any like : soft , cuts and also able to find apple diseases like cochineal etc.

Less manpower required to monitor the complete process.

SKU: n/a - Apple Sorting Machine, Food & Beverage Machinery, Sorting Equipment

Apple Grading Machines Type I. – saw Agro Industries Pvt. Ltd.

Apple Sorting Machine, Food & Beverage Machinery, Sorting EquipmentApple Grading Machines Type I. – saw Agro Industries Pvt. Ltd.

Agrosaw has state of the art manufacturing facilities to produce world class machines/plants.

The brusher is fitted with nylon bristle rollers or soft horse hair rollers rotating on their own axis. The products will be let onto the bristle rollers manually. The apples got polished while moving on the rotating brushes. Fans are provided top on the brushes to remove moisture on apple if any.

SKU: n/a - Apple Sorting Machine, Food & Beverage Machinery, Sorting Equipment

Apple Grading Machines Type II. – saw Agro Industries Pvt. Ltd.

Apple Sorting Machine, Food & Beverage Machinery, Sorting EquipmentApple Grading Machines Type II. – saw Agro Industries Pvt. Ltd.

Agrosaw has state of the art manufacturing facilities to produce world class machines/plants.

The brusher is fitted with nylon bristle rollers or soft horse hair rollers rotating on their own axis. The products will be let onto the bristle rollers manually. The apples got polished while moving on the rotating brushes. Fans are provided top on the brushes to remove moisture on apple if any.

SKU: n/a - Apple Sorting Machine, Food & Beverage Machinery, Sorting Equipment

Apple Grading Machines Type III. – saw Agro Industries Pvt. Ltd.

Apple Sorting Machine, Food & Beverage Machinery, Sorting EquipmentApple Grading Machines Type III. – saw Agro Industries Pvt. Ltd.

Agrosaw has state of the art manufacturing facilities to produce world class machines/plants.

The brusher is fitted with nylon bristle rollers or soft horse hair rollers rotating on their own axis equipped with High Quality bearing (SKF).The products will be let onto the bristle rollers manually. The apples got polished while moving on the rotating brushes. Fans are provided top on the brushes to remove moisture on apple if any. Fabricated with MS Square Pipe Structure & Heavy Duty GI Sheet.

SKU: n/a - Apple Sorting Machine, Food & Beverage Machinery, Sorting Equipment

APPLE SORTING MACHINE – Aweta

We do this based on more than 55 years of experience with in-house sorting and packing technology.

We have a perfect understanding of your product, market and the specific wishes of your customers and are able to translate your requirements into an innovative apple sorting and packing solution.

SKU: n/a - Food & Beverage Machinery, Seed Sorter Machine, Sorting Equipment

Au series – ANZAI MANUFACTURING CO. LTD.

Food & Beverage Machinery, Seed Sorter Machine, Sorting EquipmentAu series – ANZAI MANUFACTURING CO. LTD.

The thing that everyone wants but only we can provide.

That is what we aim for at Anzai Manufacturing.Introducing the Au series, the top choice in manufacturing products. Anzai Manufacturing aims to provide what everyone wants but only we can offer. Our Au-100/300/1000/2000 models offer a variety of features, including the removal of red mold grains and a reduction of DON concentration. Our products also remove black mold grains, sprouted spikelets, low amylo grains, immature grains with open grooves, green grains, and foreign substances such as buckwheat noodles and stones. Choose the Au series for superior quality and performance.

SKU: n/a - Food & Beverage Machinery, Grain Product Making Machines, Rice Processing Machine, Rice Sorter, Sorting Equipment

Belt Sorter Machine – BELTUZA Series CSV600 BI/BM – Satake Corporation

Food & Beverage Machinery, Grain Product Making Machines, Rice Processing Machine, Rice Sorter, Sorting EquipmentBelt Sorter Machine – BELTUZA Series CSV600 BI/BM – Satake Corporation

Multi-Purpose Belt Type Sorter BELTUZA Series

6 Features

1. Stable Belt Conveying

2. Shape Sorting

3. NIR Sorting (CSV600BM)

4. Automatic Sensitivity Creation

5. LED Lighting

6. Hygienic Stainless Steel BodyBELTUZA Belt Sorter Machine Trailer

: https://youtu.be/dHQTPTMF7IcSKU: n/a - Food & Beverage Machinery, Sorting Equipment, Sorting Machinery

Beltless type (stainless steel shell type) continuous magnet separator – Echo Corporation

Food & Beverage Machinery, Sorting Equipment, Sorting MachineryBeltless type (stainless steel shell type) continuous magnet separator – Echo Corporation

This sorter incorporates a high magnetic force magnet to differentiate the falling curve of products (non-magnetic materials) and foreign materials (minute magnetic materials), and continuously sorts out minute weakly magnetic foreign materials via a separator plate.

The use of a stainless steel cylinder instead of a belt overcomes the weak points of the belt type and allows for use in a wider range of fields.

SKU: n/a - Food & Beverage Machinery, Seed Sorter Machine, Sorting Equipment

BLC series – ANZAI MANUFACTURING CO. LTD.

Food & Beverage Machinery, Seed Sorter Machine, Sorting EquipmentBLC series – ANZAI MANUFACTURING CO. LTD.

The thing that everyone wants but only we can provide.

That is what we aim for at Anzai Manufacturing.Introducing the BLC series, a range of highly sought-after products from Anzai Manufacturing. Our aim is to provide something that everyone wants, but only we can deliver. The BLC-300D5 and BLC-600D5 models are equipped with an original 3CCD camera and LED technology, resulting in greatly improved foreign matter removal ability. Maintenance is made easy with these products, making them a reliable and efficient choice for any manufacturing industry. Choose the BLC series for top-of-the-line quality and performance.

SKU: n/a - Food & Beverage Machinery, Sorting Equipment, Sorting Machinery

Blizzard – Tomra Japan Ltd.

The Blizzard free-fall Pulse LED camera sorting system is a cost-effective optical sorting solution designed for the frozen food industry.

This machine removes discolored products, foreign matter, and products with abnormal shape or size while controlling yield, providing food safety and quality improvement in the frozen food industry.

SKU: n/a - Food & Beverage Machinery, Seed Sorter Machine, Sorting Equipment

BM-100D (easy camel) – ANZAI MANUFACTURING CO. LTD.

Food & Beverage Machinery, Seed Sorter Machine, Sorting EquipmentBM-100D (easy camel) – ANZAI MANUFACTURING CO. LTD.

The thing that everyone wants but only we can provide.

That is what we aim for at Anzai Manufacturing.Introducing the BM-100D (easy camel) – the product everyone wants but only Anzai Manufacturing can provide. This versatile model is compatible with a variety of raw materials such as soybeans, rice, and millet. It boasts an accurate EJ system and amplifier circuit, with a stable belt transfer method and air curtain on the glass surface. Its maintenance-friendly structure ensures easy upkeep.

SKU: n/a - Food & Beverage Machinery, Potato Grader Machine, Sorting Equipment

BMES-748 Potato General [Daichi]. – Sanshu Fork Co.

Food & Beverage Machinery, Potato Grader Machine, Sorting EquipmentBMES-748 Potato General [Daichi]. – Sanshu Fork Co.

Excellent two-in-one machine.

Processing capacity of 65 cases per hour.

Sorting is done by button operation with a dedicated indicator.

Automatic lifting and feeding device are standard.SKU: n/a - Food & Beverage Machinery, Potato Grader Machine, Sorting Equipment

BMES-748-AFDM – Yokozaki Co. Ltd.

Food & Beverage Machinery, Potato Grader Machine, Sorting EquipmentBMES-748-AFDM – Yokozaki Co. Ltd.

Pioneering the future with new ideas and new technologies

For sorting potatoes, onions, bell peppers, etc.

Equipped with an automatic metering device that activates the shutter when the specified weight is reached.

Equipped with a hoisting machine.

Raw material supply is also automatic.SKU: n/a - Food & Beverage Machinery, Seed Sorter Machine, Sorting Equipment

BS-01 (L Fant II) – ANZAI MANUFACTURING CO. LTD.

Food & Beverage Machinery, Seed Sorter Machine, Sorting EquipmentBS-01 (L Fant II) – ANZAI MANUFACTURING CO. LTD.

The thing that everyone wants but only we can provide.

That is what we aim for at Anzai Manufacturing.Introducing the BS-01 (L Fant II) from Anzai Manufacturing – the thing everyone wants but only we can provide. This product is designed to sort millet, foxtail millet, and Japanese millet, as well as sort coffee based on L value. The built-in compressor eliminates the need for additional equipment, while the high-sensitivity sensor ensures reliable selection of defective products. Get the best millet sorting and coffee roasting experience with the BS-01.

SKU: n/a - Food & Beverage Machinery, Sorting Conveyor, Sorting Equipment

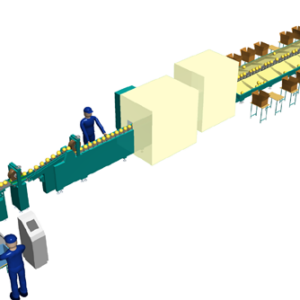

Bucket Sorter Flat Sorter Type – SHIBUYA SEIKI CO. LTD.

Food & Beverage Machinery, Sorting Conveyor, Sorting EquipmentBucket Sorter Flat Sorter Type – SHIBUYA SEIKI CO. LTD.

The object is placed on a flat belt-like bucket conveyor, which slides horizontally and receives the object to a manual filling pool conveyor with zero drop-off.

The “Bucket Sorter Flat Sorter Type” is a manufacturing product that helps sort objects efficiently. The object is placed on a flat belt-like bucket conveyor, which slides horizontally and receives the object to a manual filling pool conveyor with zero drop-off. This space-saving sorter eliminates rolling during discharge, making it easier for manual filling. With a fixed pitch discharge, the user can easily operate the sorter without any hassle. The sorter is designed to make the sorting process more efficient and less time-consuming. Its compact size saves space, making it suitable for small manufacturing facilities. The sorter is easy to operate, and its simple design makes it easy to maintain. The Bucket Sorter Flat Sorter Type is a reliable and cost-effective solution for sorting objects in a manufacturing setting. It is an ideal product for companies looking to streamline their manufacturing process and improve their productivity. With its innovative design and user-friendly features, the Bucket Sorter Flat Sorter Type is a must-have for any manufacturing facility.

SKU: n/a - Food & Beverage Machinery, Sorting Conveyor, Sorting Equipment

Bucket sorting machine, horizontal discharge type – SHIBUYA SEIKI CO. LTD.

Food & Beverage Machinery, Sorting Conveyor, Sorting EquipmentBucket sorting machine, horizontal discharge type – SHIBUYA SEIKI CO. LTD.

The object is placed on the rectangular bucket conveyor, and the bucket is tilted laterally to gently discharge the object into the receiving bin.

Introducing our Bucket Sorting Machine, Horizontal Discharge Type. This machine is designed to gently discharge objects into a receiving bin by tilting the rectangular bucket conveyor laterally. It is suitable for both weight and shape measurement methods and comes in two types: a simple and efficient 1-row, 1-grade type, and a slim 1-row, multi-grade type that can sort multiple grades simultaneously in a single row with a visual grading area. The latter is also compatible with internal quality sensors. The machine length can be shortened by discharging on both sides. Additionally, concentrated fruit grades can be discharged in a dispersed manner to ensure uniformity in packing operations. Our Bucket Sorting Machine is perfect for those in the manufacturing industry looking for a reliable and efficient way to sort and grade their products.

SKU: n/a

Are you looking for Sorting equipment products?

When selecting Sorting equipment for your company’s needs, there are several important points to consider during the comparison and evaluation process.Common Comparison Points for Any Sorting Equipment

1. Sorting Accuracy and Speed

Evaluate the sorting accuracy and speed of the equipment. Consider factors such as the detection and rejection rate of defective or non-conforming products, the capacity to handle high volumes of items, and the speed at which the equipment can sort items accurately. High sorting accuracy and speed are essential for maintaining product quality and maximizing productivity.

2. Sorting Criteria and Flexibility

Assess the equipment’s ability to sort items based on specific criteria. Determine whether the equipment can sort items by size, shape, color, weight, barcode, or other relevant attributes. Additionally, consider the flexibility of the equipment in accommodating changes to sorting criteria or handling different types of products. Flexibility in sorting criteria ensures adaptability to evolving production requirements.

3. Product Compatibility and Gentle Handling

Consider the equipment’s compatibility with the products you handle. Evaluate whether the equipment can handle fragile, delicate, or easily damaged items without compromising their quality. Gentle handling mechanisms, such as soft conveyors or adjustable sorting mechanisms, are important to prevent product damage during the sorting process.

4. Sorting Configuration and Layout

Evaluate the equipment’s configuration and its impact on your production floor layout. Consider factors such as space requirements, conveyor setup, and the equipment’s integration with your existing production line. Optimize the layout to ensure smooth material flow, minimize bottlenecks, and facilitate efficient sorting operations.

5. Integration with Other Systems

Assess the equipment’s integration capabilities with other systems in your production line, such as upstream and downstream processes, quality control systems, or data management systems. Seamless integration allows for real-time data exchange, synchronized operations, and enhanced overall process efficiency.

6. Maintenance and Serviceability

Evaluate the ease of maintenance and serviceability of the equipment. Consider features such as accessibility to critical components, ease of cleaning, and availability of spare parts. Equipment with straightforward maintenance procedures and reliable support from the manufacturer can minimize downtime and ensure continuous operation.