Other Fruit & Vegetable Machines

Showing all 8 results

- Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

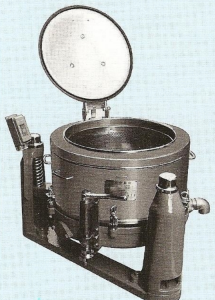

Centrifuge DT-1 Top discharge type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-1 Top discharge type – Daiei Seisakusho Co.

Motor is a high-torque motor specially designed for centrifuges

Applications

Dehydration of various vegetables, pickles, confectionery industry, ham, sausage, fish meat, livestock, tsukudani, seafood processing, dehydration of textiles, deoiling of cutting layersSKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge DT-2 Popular type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-2 Popular type – Daiei Seisakusho Co.

Noiseless dehydration.

Applications

Dehydration of cabbage and onions for dumplings and shao mai, dehydration and drying of vegetables, pickles, confectionery industry, ham, sausage, fish meat, livestock, tsukudani, fishery industry, dehydration of textiles, deoiling of cuttingSKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge DT-2B double basket type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-2B double basket type – Daiei Seisakusho Co.

Often used for de-oil recovery of tempura and dregs, and dehydration of vegetable noodles after cutting

Applications

Dehydration of tempura, tempura dregs, dehydration of prepared food period. Dehydration of cabbage and onion, dehydration of kitchen and residue.SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge DT-K with scraping device Bottom discharge type – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge DT-K with scraping device Bottom discharge type – Daiei Seisakusho Co.

Ideal for labor-saving dehydration work

Applications

Chemical industry: various metal powder crystals, calcium chloride, sodium, lime, plastics, and other chemical products

Food industry: salt production, sugar starch production, brewing, processed water products, livestock products, processed vegetable products, confectionery

Pollution: plating industry, general factories, fisheries, livestock wastewater sludge treatmentSKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge for colander DT-2SA – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge for colander DT-2SA – Daiei Seisakusho Co.

The machine uses a lightweight, easy-to-handle polypropylene colander basket for dehydration and deoiling, to prevent material from sticking out during operation, and a main body that can be divided into two parts for easy cleaning and disinfection.

Applications

Dehydration of all kinds of vegetables, root vegetables and pickles. Dehydration of marine products such as wakame seaweed and kelp, fish and meat, etc., and deoiling of tempura, fried balls, fried dregs, etc.

At present, centrifugal separators are used in food processing plants of school lunch and meal service centers, major food manufacturers, and major restaurants,

Centrifugal separators are now being used to drain cut vegetables and drain oil from fried foods.SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Centrifuge for colander DT-2SE – Daiei Seisakusho Co.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesCentrifuge for colander DT-2SE – Daiei Seisakusho Co.

The machine uses a lightweight, easy-to-handle polyethylene colander basket for dehydration and deoiling, and is designed to prevent material from sticking out during operation and to allow easy cleaning and disinfection by dividing the main body into two parts.

Applications

Dehydration of all kinds of vegetables, root vegetables and pickles. Dehydration of marine products such as wakame seaweed and kelp, fish meat, livestock meat, etc., and deoiling of tempura, fried balls, and fry shavings. Other

Currently, centrifugal separators are used for draining cut vegetables and de-oiling fried foods at school lunchrooms, meal centers, and food processing plants of major food manufacturers and restaurants.SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

High-speed spin dryer (Basket type) / Model TDS-FZ, TDS-LF – EMURA FOOD MACHINE CO.LTD.

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesHigh-speed spin dryer (Basket type) / Model TDS-FZ, TDS-LF – EMURA FOOD MACHINE CO.LTD.

For dehydration of materials after a washer.

Just need to put baskets filled with materials into the machine.

Outstanding stability and durability due to the direct motor drive!

For lettuce, cabbage, carrot or various vegetables.

SKU: n/a - Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable Machines

Vegetable Dewatering Machine – Aiho Corporation

Food & Beverage Machinery, Fruit & Vegetable Processing Machines, Other Fruit & Vegetable MachinesVegetable Dewatering Machine – Aiho Corporation

The operation is very simple, all you have to do is just placing vegetable into the basket.

This machine can remove surface water from vegetable in short time by using centrifugal force.

SKU: n/a

Are you looking for a Other Fruit & Vegetable Machines product?

When selecting Other Fruit & Vegetable Machines for your company’s needs, there are several important points to consider during the comparison and evaluation process.

1. Functionality and Features

Compare the functionality and features of different Other Fruit & Vegetable Machines. Look for features that align with your specific needs and requirements. Consider aspects such as cutting options, capacity, automation, and customization possibilities.

2. Quality and Durability

Assess the build quality and materials used in the machines. Check customer reviews and ratings to gauge the product’s durability and reliability.

3. Ease of Use

Look for machines that are user-friendly and have intuitive controls. A complex machine might require extensive training and could lead to inefficiencies.

4. Maintenance and Cleaning

Analyze the maintenance requirements and ease of cleaning for each machine. Opt for machines that are easy to maintain and have clear cleaning instructions.

5. Safety Features

Safety is paramount in any manufacturing setting. Compare the safety features of the machines, such as emergency stop buttons, safety guards, and automatic shut-off mechanisms.

6. Performance and Output

Consider the performance metrics of the machines, including processing speed, output capacity, and energy efficiency.

7. Compatibility

Ensure the selected machine is compatible with your existing production line or other machinery, if applicable.