Refrigeration & Heat Exchange Equipment

Showing 1–24 of 39 results

- Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Air nozzles – HeatTec Co. Ltd.

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentAir nozzles – HeatTec Co. Ltd.

The effectiveness of air nozzles for draining and drying varies greatly depending on the installation method, size, and slit shape.

Slit air nozzles, air knife nozzles, and blow-off nozzles can be used to discharge unbroken air evenly in a curtain-like pattern.

From liquid cutter to hot air discharge type, and from palm size to long type over 3m.

We can manufacture from a single unit in any desired length.

We can also propose energy-saving air systems using energy-saving blowers.SKU: n/a - Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

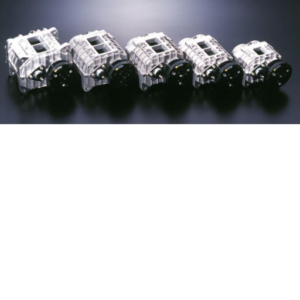

Air Pumps for Commercial Applications and Hydrogen Pumps for Fuel Cells – OGURA CLUTCH CO.LTD

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentAir Pumps for Commercial Applications and Hydrogen Pumps for Fuel Cells – OGURA CLUTCH CO.LTD

Ogura blowers provide robust long life and dependable operation in the most challenging applications.

Ogura purchased the unique supercharger design from Wankel in Germany in 1973, but it has been improved to meet the demanding, high efficiency requirements of many of today’s applications. Ranging in size from just under 6 m3/hr (TX002) to over 1212 m3/hr (TX28), Ogura’s positive displacement blower can handle applications from air to the universe’s lightest gas: Hydrogen.

When efficiency counts, Ogura delivers. Ogura’s design is one of the most efficient positive displacement pumps in the industry. These pumps can help make your next generation machine smaller, lighter and more powerful.

Hollow, aircraft grade aluminum rotors are coated with a special lightweight sealing material. This unique low inertia design helps provide the fastest response time for this type of blower.SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Air-cooled cooling plate CHP-772HS / 77HI / 44HS /55HS – Sensor Controls Co.Ltd.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentAir-cooled cooling plate CHP-772HS / 77HI / 44HS /55HS – Sensor Controls Co.Ltd.

Temperature range from a maximum of 120°C to a minimum of -20°CProvides an easy temperature environment with only a cold plate and temperature controller

This model can easily provide a temperature environment with only an air-cooled cold plate and a temperature controller.

SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Aluminum Plate Type Stationary Sensible Heat Exchanger CROSSTERM® (CROSSTERM®) – Takasago Thermal Engineering Co. Ltd.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentAluminum Plate Type Stationary Sensible Heat Exchanger CROSSTERM® (CROSSTERM®) – Takasago Thermal Engineering Co. Ltd.

Aluminum plate type direct alternating current stationary sensible heat exchanger with extremely low leakage

CROSSTERM® is an aluminum plate static DC sensible heat exchanger that recovers sensible heat from exhaust air to supply air through two adjacent plates.

SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Automatic liquid temperature controllers – KAMUI CO.LTD.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentAutomatic liquid temperature controllers – KAMUI CO.LTD.

At Kamui, we provide a wide range of heat exchangers so that we can address all of our customers’ needs.

This is an oil cooler with built-in refrigeration that automatically controls the temperature of liquids such as lubricants, hydraulic oil, cutting oil, cutting fluid, etc.

SKU: n/a - Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Band Dryer – YAMATO SANKO MFG. CO. LTD.

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentBand Dryer – YAMATO SANKO MFG. CO. LTD.

Widely used in diverse industries

The band dryer is a typical continuous convection heat transfer type of dryer, which has been improved and modified over the years.

This is a hot air type of dryer, wherein the materials are placed on a band conveyor (steel or perforated plate, etc.) and dried by hot air as they move through the drying chamber.

Generally, the band dryer forcibly passes hot air through the gaps in the material layers to dry the material.SKU: n/a - Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

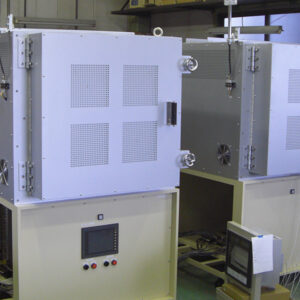

Box Dryer – YAMATO SANKO MFG. CO. LTD.

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentBox Dryer – YAMATO SANKO MFG. CO. LTD.

A dryer with a freely selectable airflow method, suitable for a wide range of applications

The box dryer is an ideal dryer for a wide range of applications, as it offers a freely selectable airflow method.

Formed materials or materials loaded into a container (tray) are inserted into a fixed shelf or trolley shelf in the drying chamber, where they are dried by hot air.

Various airflow methods are available, including horizontal airflow (lateral one-way airflow or alternating airflow) and through flow (vertical one-way airflow or alternating airflow).

The number of drying chambers can be selected, with single chamber types and multi chamber types (with reheating heater installed) available, thus enabling large volume processing.

The following models are available, which differ in the way hot air is applied to the materials.SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Elofin heaters Heat exchangers for heating and drying equipment – Katsukawa Thermal Engineering Co. Ltd.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentElofin heaters Heat exchangers for heating and drying equipment – Katsukawa Thermal Engineering Co. Ltd.

Used as a heater to heat air with steam/hot water/heating medium oil

These heaters are mainly used for heating air (gas) and are incorporated in air conditioners, drying facilities, drying equipment, etc. The structure consists of multiple elophine tubes welded into a bundle (header) and housed in a steel plate duct-type casing.

The structure consists of multiple elophane tubes welded to a bundle of tubes (header) and enclosed in a steel plate duct-type casing.

SKU: n/a - Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

FLB-NO.8 – BLOWER – Yotsuba Air Machine Manufacturing Co. Ltd

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentFLB-NO.8 – BLOWER – Yotsuba Air Machine Manufacturing Co. Ltd

Our FLB type rotary blower is an intermediate pressure & intermediate capacity pressure compressor for gas transfer. Now the machine is capable of transferring various kinds of gasses.

As a specialized company making rotary blowers, we use our cutting edge technology new design policy and make every effort to respond to your needs. We have numerous results delivering blowers made from special materials such as stainless steel and for special purposes such as circulating high-temperature/high-pressure gases. Please contact us with your needs.

SKU: n/a - Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Fluidized Bed Band Dryer – YAMATO SANKO MFG. CO. LTD.

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentFluidized Bed Band Dryer – YAMATO SANKO MFG. CO. LTD.

Usable even for materials with high moisture content, mixed particles and irregular shapes, and low particulate franture

The fluidized bed band dryer is an incredibly efficient dryer that causes minimal particulate fracture and can be used even for materials with high moisture content, mixed particles, and irregular shapes.

In this dryer, a band conveyor is positioned on a fluidized bed to convey the materials, and hot air is blown from the bed to apply a fluidized bed airflow and through-flow to the materials.

This spreads the materials vertically and constantly renews the evaporation surface area, thus making drying more efficient.SKU: n/a - Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

FUEL CELL GAS BLOWER – Yotsuba Air Machine Manufacturing Co. Ltd

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentFUEL CELL GAS BLOWER – Yotsuba Air Machine Manufacturing Co. Ltd

Special type Roots blowers for high-temperature and high-pressure gas/steam gas force feeding for new-generation fuel-cells by exploring unlimited possibilities in high-temperature and high-pressure technologies

YOTSUBA has long been directing its efforts to the research of Roots blowers for high-pressure gas circulation and force feeding, as well as the vacuum technology.

SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Heater stand-alone – HeatTec Co. Ltd.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentHeater stand-alone – HeatTec Co. Ltd.

High-quality industrial heaters can be manufactured from a single unit.

We can design a heater capacity, material, operating temperature, shape, size, etc. to suit your purpose of use and usability.

Please consult us even if you do not have drawings or specifications.SKU: n/a - Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Heating equipment, industrial machinery – HeatTec Co. Ltd.

Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange EquipmentHeating equipment, industrial machinery – HeatTec Co. Ltd.

Design and manufacture unique heating and drying equipment just for your company

Hot air, infrared, halogen lamp heaters, hot plates, super high temperature heaters, nichrome, pyromax, etc.

SKU: n/a - Blowers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

HIGH-TEMPERATURE & HIGH-PRESSURE STEAM FORCE FEED BLOWER – Yotsuba Air Machine Manufacturing Co. Ltd

Blowers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentHIGH-TEMPERATURE & HIGH-PRESSURE STEAM FORCE FEED BLOWER – Yotsuba Air Machine Manufacturing Co. Ltd

Special type Roots blowers for high-temperature and high-pressure gas/steam gas force feeding for new-generation fuel-cells by exploring unlimited possibilities in high-temperature and high-pressure technologies

YOTSUBA has long been directing its efforts to the research of Roots blowers for high-pressure gas circulation and force feeding, as well as the vacuum technology.

SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Hot air generator Cabinet heater – Katsukawa Thermal Engineering Co. Ltd.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentHot air generator Cabinet heater – Katsukawa Thermal Engineering Co. Ltd.

Environmentally friendly heating system with natural convection using steam

A hot air generator is a unit consisting of a heater and a fan.

The size of the heater and the type and selection of the fan are determined according to the amount of air flow, temperature conditions, required heat value, and intended use.While the heater for the production line is a part of the equipment, the hot air generator is a component of the drying equipment.

In drying equipment, the hot-air generator is installed on the top of the equipment or outside of the equipment, and is optimally shaped for various drying applications.SKU: n/a - Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange Equipment

KHU: A heater unit with a Bernoulli’s stirrer – Nitto Kinzoku Kogyo Co. Ltd.

- Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange Equipment

KU-DTK-PO/KU-DTK-SD: Bernoulli’s flashy stirring unit DTK type – Nitto Kinzoku Kogyo Co. Ltd.

- Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange Equipment

KU-PCN-F-J-L: Bernoulli’s flashy stirring pressure unit PCN-F-J-L type – Nitto Kinzoku Kogyo Co. Ltd.

Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange EquipmentKU-PCN-F-J-L: Bernoulli’s flashy stirring pressure unit PCN-F-J-L type – Nitto Kinzoku Kogyo Co. Ltd.

It is excellent in stirring with reduced foaming.

The container is a pressurized container with a jacket that can be temperature control and pressurized stirring.

SKU: n/a - Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange Equipment

KU-PCN-O-J-L: Bernoui flashy stirring pressure unit PCN-O-J-L type – Nitto Kinzoku Kogyo Co. Ltd.

Industrial Heaters, Industrial Machinery, Refrigeration & Heat Exchange EquipmentKU-PCN-O-J-L: Bernoui flashy stirring pressure unit PCN-O-J-L type – Nitto Kinzoku Kogyo Co. Ltd.

It is excellent in stirring with reduced foaming.

A unit with a Bernouy stirrer, stainless steel container, and valve.

SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

LS fin heater Plate fin – Katsukawa Thermal Engineering Co. Ltd.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentLS fin heater Plate fin – Katsukawa Thermal Engineering Co. Ltd.

Next Generation Fintubes

It can be called a new generation Elofin heater that solves the problem of heaters using aluminum Elofin tubes, which have durability problems. When employed in a circulating drying oven (dryer), the heat transfer area can be reduced to a maximum of about 1/2 that of an elo- fin type. In other words, if two Elofin heaters are required up to now, only one can satisfy the capacity!

SKU: n/a - Chilling Equipment, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Modular Chiller M-Pak Series – ATS Japan Corporation

Chilling Equipment, Industrial Machinery, Refrigeration & Heat Exchange EquipmentModular Chiller M-Pak Series – ATS Japan Corporation

-Chiller capable of a wide range of temperature control from -70°C to +200°C!

ATS Japan Corporation introduces the M-Pak Series multi-channel chiller.

Maximum of 4 different module combinations available (-70℃~+155℃)

Compatible with various circulating liquids

Compatible with various interfacesATS Japan Inc. has a proven track record of introducing chillers mainly in the semiconductor industry. Based on our experience of installing several thousand units, we can also customize chillers for use in other industries such as the food, medical, and physical/chemical industries. We will propose the best solution for your environment and application.

SKU: n/a - Chilling Equipment, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Natural refrigerant chiller GX-20 – ATS Japan Corporation

Chilling Equipment, Industrial Machinery, Refrigeration & Heat Exchange EquipmentNatural refrigerant chiller GX-20 – ATS Japan Corporation

No use of Freon! 20% energy savings is possible through the use of high-efficiency motors, etc.

The “GX-20” is a natural refrigerant chiller that does not use high GWP refrigerants, including CFC substitutes.

It has lower power consumption due to a high-efficiency motor and improved control, and its smaller size reduces the installation footprint.

In addition, a wide range of temperature control from -20°C to +70°C is possible.

SKU: n/a - Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange Equipment

Next generation global environmental specification [Plate & Shell heat exchanger – Kamata Industry Co.ltd.

Heat Exchangers, Industrial Machinery, Refrigeration & Heat Exchange EquipmentNext generation global environmental specification [Plate & Shell heat exchanger – Kamata Industry Co.ltd.

The plate & shell heat exchanger is a highly efficient & compact next-generation heat exchanger that combines the robustness of the multi-tube type with the efficiency of the plate type.

The Bartels plate and shell heat exchanger from Finland is a revolutionary heat exchanger that is the culmination of unique Scandinavian wisdom and ideas.

As a high-performance and compact next-generation global environmental type heat exchanger, Bartels boasts a track record of more than 40,000 units in operation worldwide since its launch in 1990.

They are highly evaluated by a wide range of industries, including energy, chemical, food, and other plants, refrigeration facilities, offshore, and marine facilities.SKU: n/a

Are you looking for a Refrigeration & Heat Exchange Equipment product?

When selecting Refrigeration & Heat Exchange Equipment for your company’s needs, there are several important points to consider during the comparison and evaluation process.

1. Cooling/Heating Capacity

Compare the cooling and heating capacity of different equipment to ensure it meets your specific requirements.

2. Energy Efficiency

Assess the energy efficiency ratings of the equipment to minimize operational costs and environmental impact.

3. Size and Footprint

Consider the physical dimensions and footprint of the equipment to ensure it fits within your available space.

4. Temperature Range

Check the equipment’s temperature range to ensure it can handle the required cooling or heating tasks.

5. Material Compatibility

Verify that the materials used in the equipment are compatible with the substances being cooled or heated to avoid contamination or reactions.

6. Maintenance and Service

Research the maintenance requirements and availability of service and technical support for the equipment.

7. Installation Requirements

Consider the installation requirements, such as power supply, ventilation, and plumbing, to ensure they align with your facility.

8. Control and Automation

Evaluate the level of control and automation features offered by the equipment for precise operation and ease of use.

9. Noise Level

Check the noise level of the equipment, especially if it will be placed in a noise-sensitive environment.

10. Warranty and Support

Check the warranty period and the manufacturer’s reputation for customer support and after-sales service.