Environmental Machinery

Showing all 16 results

- Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Electro Magnetic Drum Separator ED Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryElectro Magnetic Drum Separator ED Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

A powerful electromagnet is built into the drum, and it adsorbs ferromagnetic materials as iron on the drum surface, and moves them out of the magnetic field range by rotating the drum for separation and sorting.

Iron content collection from scrap vehicle shredder plants. Iron content collection from shredded bulky waste. Iron content collection from ash disposals at incineration facilities

SKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Electro Magnetic Suspended Separator HE Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryElectro Magnetic Suspended Separator HE Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Suspended magnetic separator is being suspended on a belt conveyor or vibrating conveyor to collect ferromagnetic materials such as iron pieces and iron lumps that are mixed in with the conveyed materials.

Iron collection from bulky waste, recyclable waste, etc.

Iron collection and removal from crushed and ash processing materialsSKU: n/a - Environmental Machinery, Industrial Machinery, Water Treatment Machinery

Electrolyte Manufacturing Equipment – WOCA World Conquest Association

Environmental Machinery, Industrial Machinery, Water Treatment MachineryElectrolyte Manufacturing Equipment – WOCA World Conquest Association

Electrolyte manufacturing equipment produces electrolyte for use in particle size analyzers (electrical resistance counters).

The electrolyte produced by the electrolyte generator not only removes foreign matter, but also allows for stable measurement in the particle size analyzer and variable electrolyte concentration.

Pure water can be used at any time.SKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

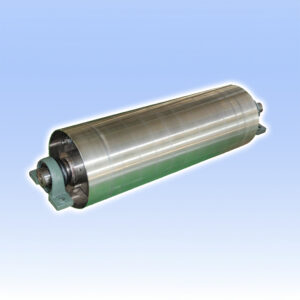

High Magnetic Pulley PP-A/K Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryHigh Magnetic Pulley PP-A/K Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

We also sell individual magnetic pulleys with high magnetic force (1.3 Tesla or higher on the pulley surface) for use in stainless steel separators.

The PP-A series with pulley surfaces of 1.3 Tesla or higher and the PP-K series with pulley surfaces of 1.5 Tesla or higher are also available depending on the application.

SKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Magnetic Pulley PP-S/N Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryMagnetic Pulley PP-S/N Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

A conveyor head pulley is replaced by a magnetic pulley with a built-in permanent magnet, which is used to collect more ferromagnetic materials.

The pulley surface magnetic force is about 0.1 Tesla for ferrite magnets and about 0.3 Tesla for neodymium magnets.

SKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Non-ferrous Metal Separator MSH Series (Standard type) – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryNon-ferrous Metal Separator MSH Series (Standard type) – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

While the rotor with permanent magnets arranged around its circumference is rotated at high speed, and the powerful alternating magnetic field on the drum surface generates eddy currents. Meanwhile, nonferrous metals such as aluminum in the material being conveyed on the conveyor, should be separated by the eddy current propulsive force.

Collecting of non-ferrous metals at waste vehicle shredder plants and waste home appliance recycling plants

Separation of aluminum cans and PET bottles, etc. at a resource-recycling plantSKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Non-ferrous Metal Separator MSK Series (High performance type) – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryNon-ferrous Metal Separator MSK Series (High performance type) – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

This is a high performance type with higher magnetic force and poles than the standard type magnetic rotor. It is suitable for separating and collecting nonferrous metals with smaller diameters than the standard type.

Collecting of nonferrous metals at waste vehicle shredder plants and waste home appliance recycling plants

Removal of nonferrous metal particles in the wood recycling fieldSKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Permanent High Magnetic Drum Separator HND Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryPermanent High Magnetic Drum Separator HND Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Permanent magnet type drum magnetic separator with stronger drum surface magnetic force than the ND series.

Collection of feebly magnetic materials mixed in powder, etc. (removal of iron rust foreign matter, etc. mixed in carbon raw materials)

Collection of rare metals from crushed cell phones and air conditionersSKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Permanent Magnetic Drum Separator FD/ND Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryPermanent Magnetic Drum Separator FD/ND Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

A powerful permanent magnet is built into the drum instead of an electromagnet.

Iron content collection from scrap vehicle shredder plants

Iron content collection from shredded bulky waste

Iron content collection from ash disposals at incineration facilitiesSKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

Permanent Magnetic Suspended Separator HP Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryPermanent Magnetic Suspended Separator HP Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Permanent magnet suspended separators are suspension separators that use powerful permanent magnets instead of electromagnets.

Iron collection at recyclable waste plant

Collecting of relatively large iron pieces from construction waste, etc.

Iron collection and removal from glass, wood chips, etc.SKU: n/a - Environmental Machinery, Industrial Machinery, Water Treatment Machinery

Sewage treatment equipment, various measuring tanks – shimizu industry

Environmental Machinery, Industrial Machinery, Water Treatment MachinerySewage treatment equipment, various measuring tanks – shimizu industry

Sewage treatment equipment and various types of measuring tanks have a very wide range of uses and applications.

They are installed inside septic tanks and are also used for sedimentation and separation at water and sewage treatment plants.

SKU: n/a - Environmental Machinery, Industrial Machinery, Waste Treatment Machinery

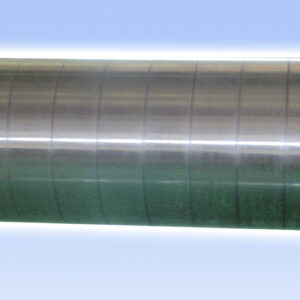

Stainless Separator PP-K Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Environmental Machinery, Industrial Machinery, Waste Treatment MachineryStainless Separator PP-K Series – Mitsubishi Nagasaki Machinery Mfg. Co. Ltd.

Equipped with a high magnetic force magnet pulley with a built-in high magnetic force permanent magnet (rare earth magnet), and that enables the separation of feeble magnetic material that cannot be collected by the magnetic separator.

Separation of feeble magnetic materials (stainless steel, dry cell batteries, rare metals) mixed in plastic raw materials and shredded materials

SKU: n/a

Are you looking for a Environmental Machinery product?

When selecting Environmental Machinery for your company’s needs, there are several important points to consider during the comparison and evaluation process.

1. Environmental Compliance

Ensure that the environmental machinery meets all relevant environmental regulations and standards to avoid legal issues and penalties.

2. Application Specificity

Determine the specific environmental application you need the machinery for, such as air pollution control, water treatment, waste management, or noise reduction.

3. Capacity and Throughput

Check the capacity and throughput of the machinery to ensure it can handle the volume of waste or pollutants generated by your operations.

4. Efficiency and Performance

Assess the efficiency and performance of the environmental machinery in terms of pollutant removal, energy consumption, and overall effectiveness.

5. Technology and Innovation

Consider the use of advanced technologies and innovations in the machinery that can improve its performance and reduce environmental impact.

6. Maintenance and Service

Evaluate the ease of maintenance and availability of service and support for the machinery to ensure optimal functioning and minimize downtime.

7. Integration and Compatibility

Check whether the environmental machinery can be seamlessly integrated into your existing production processes and if it is compatible with other equipment.

8. Footprint and Space Requirements

Consider the size and footprint of the machinery, especially if space is limited in your manufacturing facility.

9. Cost and ROI

Compare the initial cost of the environmental machinery with its long-term benefits and return on investment in terms of environmental compliance and cost savings.

10. Environmental Impact

Assess the overall environmental impact of the machinery’s operation, such as energy consumption, emissions, and waste generation.