Sensor

Showing all 4 results

- Image Sensor, Industrial Machinery, Sensor

Dust Camera PTC-1040 Dynamic Differential Image Observer – MSJ Creative research Laboratory

Image Sensor, Industrial Machinery, SensorDust Camera PTC-1040 Dynamic Differential Image Observer – MSJ Creative research Laboratory

Visualization of fine particles can be easily observed in combination with appropriate illumination.

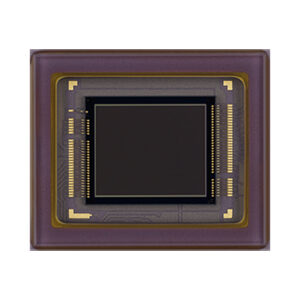

Images from an ultra-compact, high-sensitivity, high-resolution monochrome CCD camera are processed with 10-bit (1024 gradations) high gradation for real-time differential processing.

The differential image effect enables identification of scratches and faint contrasts that are normally difficult to distinguish.

The camera, lens, and processing function board are integrated into one small unit measuring 90 x 140 x 40. The light weight (300g) makes it easy to carry and observe.SKU: n/a - Image Sensor, Industrial Machinery, Sensor

High Resolution Printed Still Image Device Image Checker DST-2500 – MSJ Creative research Laboratory

Image Sensor, Industrial Machinery, SensorHigh Resolution Printed Still Image Device Image Checker DST-2500 – MSJ Creative research Laboratory

The Image Checker DST-2500 monitors register marks, halftone dots, color tone, missing barcodes, and other print quality in gravure, form, label, and flexographic printing with high-quality still images.

Automatic monitoring of register misalignment

Automatic detection and alarm of misalignment beyond a set value.High-definition image display

High-density images of 1392 (width) × 1040 (height) are more than four times higher in quality than conventional models.SKU: n/a

Are you looking for a Sensor product?

1. Performance

Consider the performance of the sensors, including factors such as accuracy, precision, response time, and resolution. Evaluate how well the sensor can measure the desired parameters and if it meets the required performance specifications.

2. Reliability and Durability

Assess the reliability and durability of the sensors. Look for features like robust construction, resistance to environmental conditions (e.g., temperature, humidity), and a long lifespan. Reliability and durability are crucial to ensure consistent performance and reduce maintenance costs.

3. Sensitivity and Range

Evaluate the sensitivity and range capabilities of the sensors. Determine the minimum and maximum values they can accurately detect and measure. Consider if the sensor’s sensitivity aligns with the required level of precision for your application.

4. Compatibility

Check the compatibility of the sensors with your existing systems or equipment. Ensure that the sensor’s output signals, communication protocols, and connectors are compatible with your data acquisition or control systems. Compatibility issues can lead to integration difficulties and inefficiencies.

5. Cost-effectiveness

Consider the overall cost-effectiveness of the sensors. Assess the initial purchase cost, maintenance requirements, and any additional expenses such as calibration or software integration. Balancing the cost with the desired performance and long-term benefits is essential.