Sensor

Showing 1–24 of 47 results

- Electronic Components, Sensor

Analog Linear Output Type HGAR Series – Alps Alpine Electronics Inc.

This high output analog output sensor is suited for high resolution detection of absolute angle and position.

Type : Angle (Surface mount) ・ Size : MSOP-8: 2.95×4.0×1.1mm, DFN: 1.8×1.05×0.65mm, DFN: 0.83×0.5×0.3mm, TSSOP8: 3.0×4.9×1.1mm, TSSOP16: 5.0×6.4×1.1mm ・ Drive voltage : 5.5V max.

SKU: n/a - Electronic Components, Sensor

-300x300.jpg)

Combustion Pressure Sensor (In-vehicle use) – CITIZEN FINEDEVICE CO.LTD.

Electronic Components, SensorCombustion Pressure Sensor (In-vehicle use) – CITIZEN FINEDEVICE CO.LTD.

The combustion sensors concentrate the Citizen Group’s piezoelectric crystal, ceramic and metalworking technology along with the technology to mass produce compact precision components.

In addition to the conventional development applications, they can be installed in the internal combustion engines of mass production vehicles to improve compliance with environmental regulations and fuel economy.

SKU: n/a - Electronic Components, Sensor

DUS-A Series – Capacitive Touchscreen – DMC Co. Ltd.

DMC’s Flagship Product, Glass/Glass Capacitive Touchscreen

GLASS SENSOR PCAP

Capacitive Glass Sensor Touchscreen

Glass-glass structure touchscreen suitable for industrial use. Compared with film-structured touchscreens, it has higher durability against impact and ultraviolet rays.SKU: n/a - Electronic Components, Sensor

DUS-F Series – Touchscreen with cover-glass – DMC Co. Ltd.

Light and Thin, Film-based Touch Screens with Cover Glass

FILM SENSOR CG-PCAP

Film-based Touchscreens with Cover GlassCover glass added on standard film/film touchscreen models featuring thinness and lightness. Film/film touch sensor is light and thin even with cover glass, and fit to limited space in chassis design.

SKU: n/a - Electronic Components, Sensor

Fermenting Machine “LEVAIN Series” – Aicohsha Manufacturing Co.Ltd.

Fermenting Machine

This machine that solves the problems, in which temperature, time and mixing are automatically controlled. Production of yeast, which is difficult but automatically controlled, can now be performed by any worker.

SKU: n/a - Electronic Components, Sensor

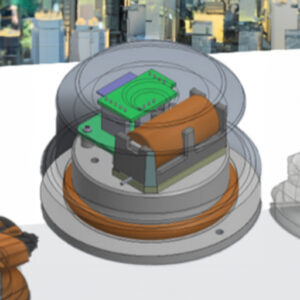

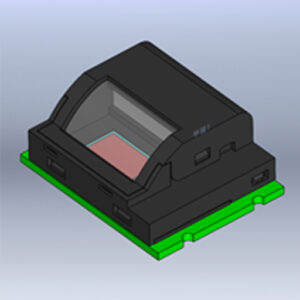

FLCOS – CITIZEN FINEDEVICE CO.LTD.

Suits a wide range of applications due to ultra-miniaturization.

We have realized displays with the world’s highest level of high-speed responsiveness, high resolution, high definition and high luminance, including mass production of the world’s only “LCOS using a ferroelectric LCD (= FLCOS)”

SKU: n/a - Electronic Components, Sensor

HDC3022 – Texas Instruments Incorporated.

0.5% RH digital humidity sensor with permanent IP67 filter

The HDC302x is an integrated capacitive based relative humidity (RH) and temperature sensor. It provides high accuracy measurements over a wide supply range (1.62 V – 5.5 V), along with ultra-low power consumption in a compact 2.5-mm × 2.5-mm package. Both the temperature and humidity sensors are 100% tested and trimmed on a production setup that is NIST traceable and verified with equipment that is calibrated to ISO/IEC 17025 standards.

SKU: n/a - Electronic Components, Sensor

Humidity Sensors CHS Series – TDK Electronics Factories Inc.

TDK offers high-accuracy sensing elements achieved by our own polymeric materials and assembled Humidity Sensor products that are extremely simple to apply due to our unique circuit designing technology.

These variable resisting humidity sensing elements are highly sensitive and highly accurate due to TDK’s unique manufacturing technology for polymeric materials. They feature high accuracy at ±5%RH, high accuracy, high sensitivity, compactness, high response and low-hysteresis characteristics.

Assembled Humidity Sensor products are compact products that are extremely simple to use and control as they run with DC power and DC voltage outputs. The screw-on types can be easily mounted onto where detections are to be made.

They feature a wide humidity detection range of 5 to 95(%)RH, high humidity detection precision of ±3%RH to ±7%RH, and low-hysteresis characteristics.

They can be used for a wide variety of applications such as printers, refrigerators (outside the refrigerators and for vegetable compartment humidity management), air conditioners (indoor humidity management), and air conditioning equipment at plant factories.SKU: n/a - Electronic Components, Sensor

Knock Sensor – NGK SPARK PLUG CO.LTD.

A sensor that detects the knocking vibration of the engine with piezoelectric ceramics, used in spark advance control, will contribute to the improvement and fuel economy of the engine performance.

Application

Piezoelectric ceramic sensor for the detection of vibration caused by engine knocking. Knock sensors are used for ignition timing control that contributes to improved engine performance and fuel economy.SKU: n/a - Electronic Components, Sensor

NOx Sensor – NGK SPARK PLUG CO.LTD.

In order to respond to the recent strict NOx regulation, precise NOx detection has been requested.

NOx Sensor for NOx aftertreatment system

The NOx sensor is part of the NOx reduction aftertreatment system used in diesel vehicles with urea based SCR systems. The sensor located upstream of the SCR catalyst directly measures the engine-out NOx gas concentration, which helps determine the optimum amount of urea injection. The NOx sensor downstream of the SCR catalyst is used to monitor the performance of the catalyst. Accurate NOx measurement is in high demand to comply with increasingly strict NOx emissions regulations. The NOx sensor is also capable of measuring O2 concentration, just like a wide range air-fuel sensor.SKU: n/a - Electronic Components, Sensor

Oil Detection Sensor – RIKO Float Technology CO.LTD.

Superb Preciseness can be found in the diversified applications, from the sensors to be assembled with machines to the ones for large tanks.

Oil sensor detects the level of oil, when engine gets started.

Oil sensor will switch on the alarm light or stop the engine, when it detects the oil level too low.SKU: n/a - Electronic Components, Sensor

Oil-level Sensors – Ubukata Manufacturing Co.

In the air-conditioning equipment essential to modern-world life, these continuously monitor the operating environment.

POINT

Detection of Low Oil Levels in Compressors

These make it possible to detect the amount of oil inside the sealed containers of coolant compressors.

This can help to prevent seizing or other malfunction due to low oil levels inside compressor containers.SKU: n/a

Are you looking for a Sensor product?

1. Performance

Consider the performance of the sensors, including factors such as accuracy, precision, response time, and resolution. Evaluate how well the sensor can measure the desired parameters and if it meets the required performance specifications.

2. Reliability and Durability

Assess the reliability and durability of the sensors. Look for features like robust construction, resistance to environmental conditions (e.g., temperature, humidity), and a long lifespan. Reliability and durability are crucial to ensure consistent performance and reduce maintenance costs.

3. Sensitivity and Range

Evaluate the sensitivity and range capabilities of the sensors. Determine the minimum and maximum values they can accurately detect and measure. Consider if the sensor’s sensitivity aligns with the required level of precision for your application.

4. Compatibility

Check the compatibility of the sensors with your existing systems or equipment. Ensure that the sensor’s output signals, communication protocols, and connectors are compatible with your data acquisition or control systems. Compatibility issues can lead to integration difficulties and inefficiencies.

5. Cost-effectiveness

Consider the overall cost-effectiveness of the sensors. Assess the initial purchase cost, maintenance requirements, and any additional expenses such as calibration or software integration. Balancing the cost with the desired performance and long-term benefits is essential.