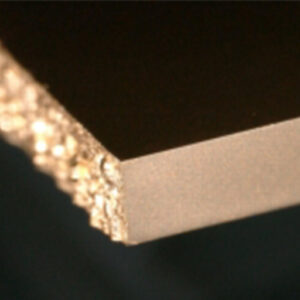

Insulation type Cu-AlN-Cu submounts – TECNISCO LTD.

This is a heat sink for high-power LD (Laser diode) modules.

Three-layer composition achieves both high thermal conductivity and insulation quality. Control of Cu plating thickness makes the heat sink match with the LD, resulting in higher power and longer life of the LD module. Because pullback is not required on the critical edge area, it has a high degree of freedom in designing. Moreover, it can be applied to a variety of application by this freedom in design.

Report Abuse

Features

- AlN + Cu composite material to achieve higher thermal conductivity and insulation quality

- CTE (coefficient of thermal expansion) matching with the LD (Laser diode)

・Adjusting Cu and AlN thickness makes it possible to control CTE - Ideal for multi-emitting type LD

- Pullback is not required on the critical edge area

・Ideal for P side down type LD - AuSn/AuGe solder vapor deposition

- Easy alignment with LD on the sharp edge

・Edge radius less than 20 μm

Characteristics comparison data<Reference>

| Unit | Material | AlN | CuW(10/20) | |

|---|---|---|---|---|

| Material features | − | Insulation | Insulation | Conductive |

| Thermal conductivity | W/m・K | 190〜250※ | 170 | 180/200 |

| CTE | ppm/℃ | 6〜10※ | 4.6 | 6.5/8.3 |

| Electric-resistance | Ω・m | – | – | 5.3/4.0 (×10-8) |

| Work voltage | V | <200 | <200 | NA |

| Relative permittivity (@1 MHz) | – | 9 | 9 | NA |

| Dissipation factor (Tan δ ) | – | 5×10-4 | 5×10-4 | NA |

※Controllable by design

End user market / Applications

Industrial laser

- Laser equipment for welding, cutting, marking, surface treatment(e.g. annealing), etc

- Medical laser equipment for ophthalmology and epilation, and endoscopes,etc

Semiconductors

- Medical laser equipment for ophthalmology and epilation, and endoscopes,etc

Digital equipment

- Laser printers, Digital multifunction-printers,etc

Two Core Competences of TECNISCO Business”Metal Components” and “Glass Components”

Since we launched our small business as processing service company mainly for cutting and grinding in 1970, we have been trying to provide best quality service and solution for our customers with Cutting, Grinding, Polishing, Metalizing and Bonding. At present, we are still developing and evolving uniquely our core capabilities by combination of state-of-the-art leading-edge processing technologies as “Cross-edge” technology resulting in becoming Metal Components and Glass Components two core competences of our business.

We would make a commitment to dedicate ourselves to provide best quality and solution to meet our customer demands with ingenious and state-of-the-art solution ranging from prototype to mass production.

Address

2-2-15, Minami-Shinagawa, Shinagawa-ku, Tokyo, 140-0004, Japan

Supplier Information

- Store Name: TECNISCO, LTD.

- Vendor: TECNISCO, LTD.

- Address: 140-0004

Tokyo 2-2-15

Minami-Shinagawa

- Industrial Laser Equipment, Industrial Machinery, Laser Equipment Parts

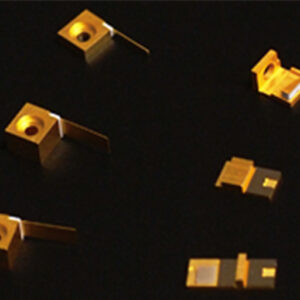

CuW submounts – TECNISCO LTD.

Industrial Laser Equipment, Industrial Machinery, Laser Equipment PartsCuW submounts – TECNISCO LTD.

This CuW submount is used as a heat sink for high power LD modules.

Alignment with LD, and sharp edge and control of warpage for effective thermal conductivity are available.

Redundant solder can be controlled in AuSn vapor deposition on the LD bonding area.SKU: n/a - Industrial Laser Equipment, Industrial Machinery, Laser Equipment Parts

Microchannel cooler – TECNISCO LTD.

Industrial Laser Equipment, Industrial Machinery, Laser Equipment PartsMicrochannel cooler – TECNISCO LTD.

Joint program with Fraunhofer ILT (Germany) leads to the development of new-structured microchannel heat sink which gives the high power LD module a longer life.

Complement effect between Cu and Mo and technology of inside channels make it low electric-resistant and CTE-matched with LD. Au coating on the inside of the channels results in the improvement in corrosion prevention.

SKU: n/a - Industrial Laser Equipment, Industrial Machinery, Laser Equipment Parts

Mounts / Carriers – TECNISCO LTD.

Industrial Laser Equipment, Industrial Machinery, Laser Equipment PartsMounts / Carriers – TECNISCO LTD.

Any type of carriers from C-mount to full-customized carriers can be manufactured according to the customers’ requirements.

Our “ Cross-edge ” technology including cutting, plating, vapor deposition, and bonding, gives you a one-stop solution.

SKU: n/a - Electronic Components, Module

TECNISCO Advanced Materials (TAM) – TECNISCO LTD.

This material features an excellent thermal conductivity and a relatively low thermal expansion that no past materials were capable of.

Combining our conventional ingenious technology and experience, we have succeeded in creating a long-lasting, reliable material beneficial for high power applications.

SKU: n/a