This is the method for setting the “zero point” of printing pressure, a characteristic feature of Micro-Tech printing machines.

Work Procedure for Setting the “Zero Point”

Once the printing conditions are set, follow the steps below to establish the “zero point.”

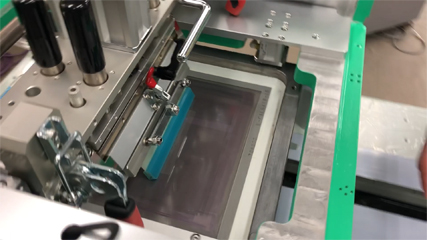

Step 1: Insert thin paper between the screen and the table

Step 2: Lower the squeegee pressure to 0.10 MPa

Step 3: Lower the squeegee head and lightly pull the thin paper

Pulling the thin paper reveals that it can be easily moved. This is because the squeegee pressure is extremely low, resulting in insufficient printing pressure and a gap between the squeegee and the table.

Step 4: Raise the squeegee head and slightly increase the squeegee pressure

In this step, it was increased to 0.11 MPa.

Step 5: Lower the squeegee head again and lightly pull the thin paper

With a slightly increased printing pressure, the squeegee touches the paper. However, it appears there is still a slight gap.

Step 6: Raise the squeegee head again and slightly increase the squeegee pressure

In this step, it was increased to 0.12 MPa.

Step 7: Lower the squeegee head again and lightly pull the thin paper

This time, the paper is firmly held by the squeegee. Repeating Steps 3-4 allows you to find the minimum printing pressure at which the squeegee stably touches the paper, which is the essence of “zero point” setup.

In this example, “0.12 MPa” is considered the “zero point.”

Products Featured in This Article

Screen Printing Machine MT-320 Series

Printing Area: 150mm. A compact screen printing machine that incorporates all the necessary functions. It is suitable for small-sized printing with a printing area of 150mm or less. Ideal for research and development purposes.

Translated by GPT