Plastic Processing Machines

Showing all 5 results

- Industrial Machinery, Plastic and Rubber Machinery, Plastic Processing Machines

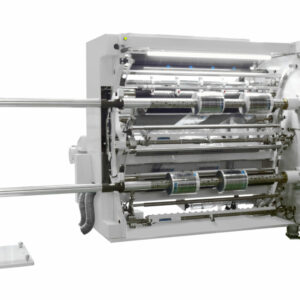

Duplex Center Drive Slitter Rewinder HDF-306V-1300 – HAGIHARA INDUSTRIES INC.

Industrial Machinery, Plastic and Rubber Machinery, Plastic Processing MachinesDuplex Center Drive Slitter Rewinder HDF-306V-1300 – HAGIHARA INDUSTRIES INC.

High performance and high function model

Main Use

Battery materials(Electrode・Separator・Aluminum Pouch), Optical materials (Polarizers, diffusion films)SKU: n/a

Are you looking for a Plastic Processing Machines product?

When selecting Plastic Processing Machines for your company’s needs, there are several important points to consider during the comparison and evaluation process.

1. Machine Type and Function

Identify the specific type of plastic processing machine you need, such as injection molding machines, extruders, blow molding machines, or thermoforming machines, based on your production requirements.

2. Production Capacity

Check the production capacity of the machine in terms of output per hour or cycle to ensure it can meet your manufacturing demands.

3. Material Compatibility

Ensure the machine is compatible with the types of plastic materials you use in your production process.

4. Automation and Controls

Evaluate the level of automation and control features offered by the machine, such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs), to enhance efficiency and ease of operation.

5. Energy Efficiency

Consider the energy consumption and efficiency of the machine to minimize operational costs and environmental impact.

6. Maintenance and Service

Check the maintenance requirements and availability of service support for the machine to ensure smooth and reliable operation.

7. Safety Features

Ensure the machine has necessary safety features like emergency stop buttons, safety guards, and interlocks to protect operators and prevent accidents.

8. Footprint and Space Requirements

Evaluate the physical size and footprint of the machine to ensure it fits into your production facility without causing space constraints.

9. Quality and Consistency

Look for machines that offer consistent and high-quality output to meet product specifications and customer requirements.

10. Cost and Return on Investment (ROI)

Compare the initial investment cost with the potential return on investment, considering the machine’s efficiency, productivity, and operational cost savings.