Laboratory Centrifuge

Showing all 3 results

- Lab Supplies, Laboratory Centrifuge, Testing Instrument & Equipment

Centrifugal Dryer DT-H – Daiei Seisakusho Co.

Lab Supplies, Laboratory Centrifuge, Testing Instrument & EquipmentCentrifugal Dryer DT-H – Daiei Seisakusho Co.

The machine absorbs heat from the sheathed heater on the top lid by centrifugal force generated by the basket rotation, so there is no heat loss and the products are dehydrated and dried evenly in a short time.

Applications

Drying and dehydration of plated products, barrel finishing machines, plastics, parkerite, and surface treatmentsSKU: n/a - Lab Supplies, Laboratory Centrifuge, Testing Instrument & Equipment

Centrifuge DT-C Foot-operated side discharge type – Daiei Seisakusho Co.

Lab Supplies, Laboratory Centrifuge, Testing Instrument & EquipmentCentrifuge DT-C Foot-operated side discharge type – Daiei Seisakusho Co.

Ideal for screws, small processed products, plastic processed products, etc.

Applications

For deoiling screws, vaults, rivets, small parts, small plated parts, and post-barrel dehydrationSKU: n/a - Lab Supplies, Laboratory Centrifuge, Testing Instrument & Equipment

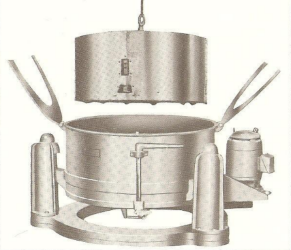

Centrifuge DT-M Suspension type – Daiei Seisakusho Co.

Lab Supplies, Laboratory Centrifuge, Testing Instrument & EquipmentCentrifuge DT-M Suspension type – Daiei Seisakusho Co.

This deoiling machine is equipped with a removable take-out basket.

Applications

Deoiling for vaults, nuts, rivets, automatic machines, turret workpieces, and cutting chipsSKU: n/a

Are you looking for a Laboratory Centrifuge product?

1. Capacity and Speed

Consider the capacity and speed of the laboratory centrifuge. Evaluate the maximum sample volume it can accommodate and the rotational speed it can achieve. Ensure that the capacity and speed align with your specific application requirements.

2. Rotor Options

Assess the available rotor options for the laboratory centrifuge. Different rotors are designed for specific applications and sample types. Consider the compatibility of the rotors with your samples and the ease of rotor exchange for flexibility in experimental setups.

3. Control and Programming

Evaluate the control and programming features of the laboratory centrifuge. Look for intuitive interfaces, programmable settings, and user-friendly operation. Advanced features such as programmable acceleration and deceleration profiles can provide precise control over the centrifugation process.

4. Safety Features

Ensure that the laboratory centrifuge incorporates necessary safety features. Look for features such as lid-locking mechanisms, imbalance detection, and automatic lid opening at the end of a run. Safety features contribute to the protection of users and prevent damage to the equipment.

5. Noise and Vibration

Consider the noise and vibration levels produced by the laboratory centrifuge. Excessive noise and vibration can be disruptive and affect the accuracy of measurements or experiments. Look for centrifuges with noise-reduction technologies and robust construction to minimize these effects.