Micro Squeegee Series – Micro-tec Co. Ltd.

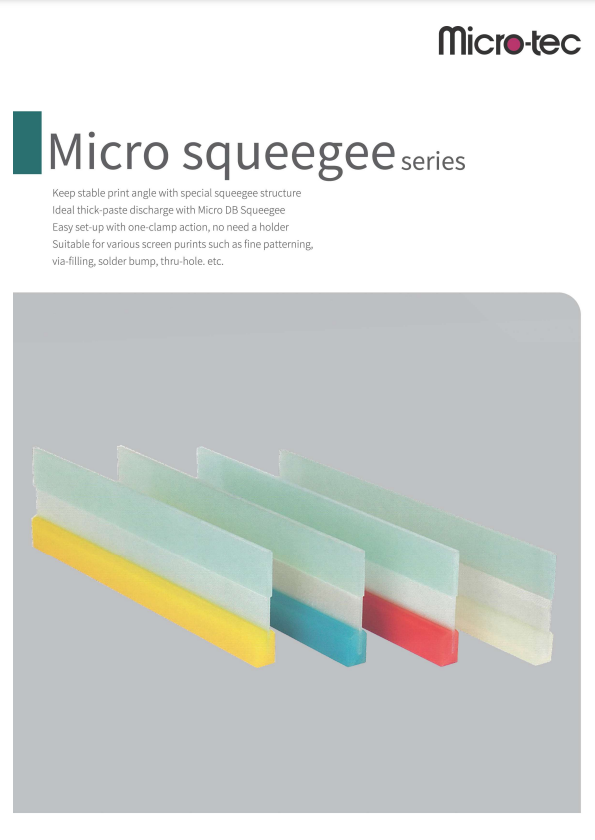

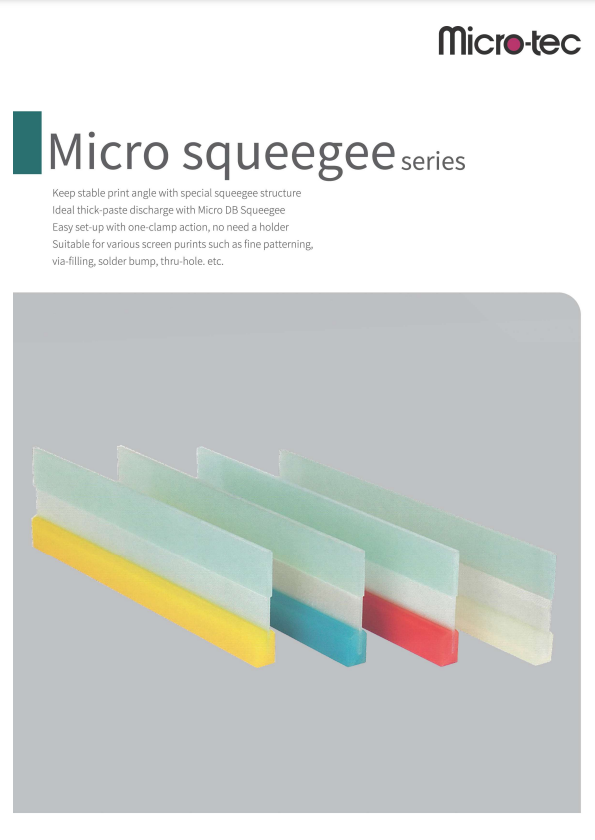

Micro-Tec’s original squeegee!

The decisive factor for screen printing is the squeegee. It is important to keep the attack angle constant in order to obtain stable print results. The Micro squeegee has a composite structure of urethane rubber (also silicon rubber) and a glass epoxy core material, and the weight of the squeegee head can be reduced, making it an ideal squeegee for practicing the proper printing process.

Report Abuse

Features

It has excellent polishing resistance and a sharp polished surface can be obtained.

The attack angle can be kept constant due to the composite structure with the glass epoxy core material.

There is little bending and deformation, and uniform printing is possible with stable printing pressure.

If you use S80, it can also be used for γ-butyl lactone.

We have 4 types to suit your needs.

(If you use the Micro DB Squeegee Series, the squeegee itself has an angle or radius, so stable paste rolling can be obtained.)

Specifications

Various Micro squeegees / Micro silicon squeegee specifications

| Type | Micro squeegee | Micro silicon squeegee | ||||

|---|---|---|---|---|---|---|

| Hardness | Y60 | B70 | R80 | S80 | ||

| 60°±5° | 70°±5° | 80°±5° | 80°±5° | |||

| Cut size tolerance | ±2mm | ±2mm | ||||

| Angle polishing | From 70 ° to 90, angle polishing is possible every 5 ° | |||||

| Longest dimension | 550mm | 400mm | ||||

DB squeegee/DB-R squeegee specifications

| Type | DB squeegee | DB-R squeegee | ||||

|---|---|---|---|---|---|---|

| Hardness | Y60 | B70 | R80 | Y60 | B70 | R80 |

| 60°±5° | 70°±5° | 80°±5° | 60°±5° | 70°±5° | 80°±5° | |

| Cut size tolerance | ±2mm | ±2mm | ||||

| Angle polishing | every 5 ° | Not possible | ||||

| Longest dimension | 1500mm | 1000mm | ||||

Ability of Micro squeegee

A glass epoxy material is used for the core material of the squeegee, and the squeegee has a waist, so a stable attack angle can be maintained. In addition, it is easy to put on and take off because it does not require a squeegee holder.

Create the future of Printable electronics!

The specialized equipment manufacturer for

printing, painting, applying materials and even cutting substrates.

The reason to choose Micro-Tec

“Want to see the happy faces of our customers” is Micro-tec’s belief.

At that belief, provide various electronic component manufacturing equipment such as screen printing machines.

We can also prepare the dryers after printing. We propose wide range of dryer products from belt type to batch type according to your needs.

We have achieved this by providing consistent services in-house,

from sales staff who are familiar with screen printing and equipment,

to technology, manufacturing and assembly, and after-sales service after delivery.

About Micro-tec service

We customize and propose screen printing machines, MLCC / LTCC related equipment (laminators, cutting machines, terminator, etc.), transport equipment, automatic production lines, drying furnaces, etc. according to the customer’s purpose and application.

And we have many distributors overseas, and provide services from a global perspective.

Need more info ?

Micro-tec Micro squeegee Series

Micro-tec Co., Ltd.

Supplier Information

- Store Name: Micro-tec Co., Ltd.

- Vendor: Micro-tec Co., Ltd.

- Address: 279-0011

Chiba Urayasu 1-5-2 Irifune

- Industrial Machinery, Other Machinery & Industrial Equipment

Cutting machine MTC Series – Micro-tec Co. Ltd.

Industrial Machinery, Other Machinery & Industrial EquipmentCutting machine MTC Series – Micro-tec Co. Ltd.

Cut to high quality

Cut ceramic green sheet for electronic components such as MLCC, LTCC, HTCC.

Can cut 0402, 0603 chip.

Easy operation with touch panel and joystick.

Cutting speed improved by 30% (compared to our old model).

No need to replace holder, easy blade replacement.

Options: Blade spill inspection, autofocus, automatic fastmark search.SKU: n/a - Industrial Machinery, Printing Machine, Screen Printers

Screen printer・MT-650 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MT-650 series – Micro-tec Co. Ltd.

The MT-650 series is a small to medium-sized multipurpose screen printer. Vibration during printing is reduced by adopting a steel belt for the squeegee head driving unit.

The MT-650 series is a small to medium-sized multipurpose screen printer. Vibration during printing is reduced by adopting a steel belt for the squeegee head driving unit.

SKU: n/a - Industrial Machinery, Printing Machine, Screen Printers

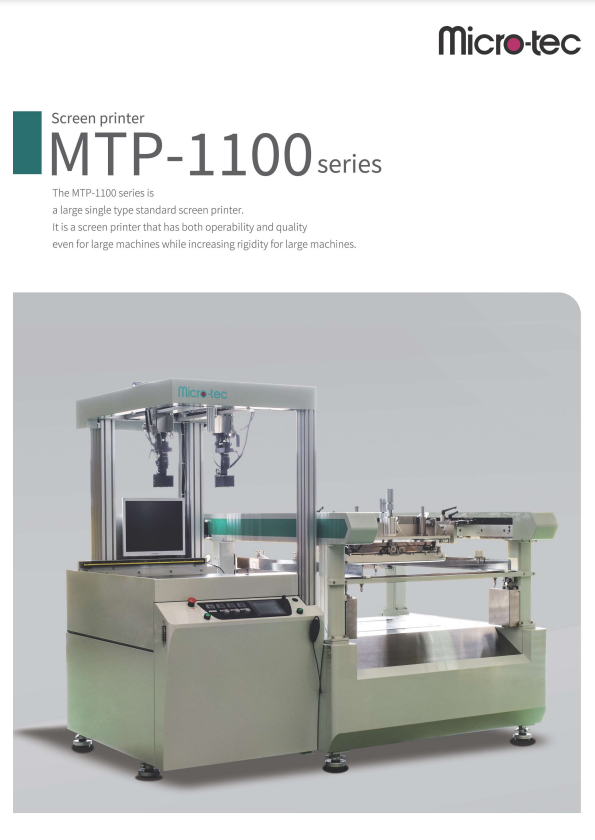

Screen printer・MTP-1100 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MTP-1100 series – Micro-tec Co. Ltd.

The MTP-1100 series is a large, versatile screen printer. By adopting a wedge method (same for MT-650 series) for driving the table, smooth operation is possible even with a large size.

The MTP-1100 series is a large, versatile screen printer. By adopting a wedge method (same for MT-650 series) for driving the table, smooth operation is possible even with a large size.

The screen is compatible with 950 to 1100 mm and can be used for printing large areas such as multi-cavity boards.SKU: n/a - Industrial Machinery, Printing Machine, Screen Printers

Screen printer・MT-320 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MT-320 series – Micro-tec Co. Ltd.

The MT-320 series is a compact, versatile screen printer.High rigidity is achieved by setting four guide shafts on a highly rigid cast bed and fixing the printing frame.

The MT-320 series is a compact, versatile screen printer.High rigidity is achieved by setting four guide shafts on a highly rigid cast bed and fixing the printing frame.

SKU: n/a - Industrial Machinery, Printing Machine, Screen Printers

Screen printer・MTP-850 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MTP-850 series – Micro-tec Co. Ltd.

The rigidness of the larger machines such as MTP-1100 has been inherited and the operability has also been improved pursuing better printability on film devices and so forth.

MT-850 is a medium-sized stand-alone screen printer with approx. 450mm x 450mm printable area maximum. The rigidness of the larger machines such as MTP-1100 has been inherited and the operability has also been improved pursuing better printability on film devices and so forth.

SKU: n/a

Features

It has excellent polishing resistance and a sharp polished surface can be obtained.

The attack angle can be kept constant due to the composite structure with the glass epoxy core material.

There is little bending and deformation, and uniform printing is possible with stable printing pressure.

If you use S80, it can also be used for γ-butyl lactone.

We have 4 types to suit your needs.

(If you use the Micro DB Squeegee Series, the squeegee itself has an angle or radius, so stable paste rolling can be obtained.)

Specifications

Various Micro squeegees / Micro silicon squeegee specifications

| Type | Micro squeegee | Micro silicon squeegee | ||||

|---|---|---|---|---|---|---|

| Hardness | Y60 | B70 | R80 | S80 | ||

| 60°±5° | 70°±5° | 80°±5° | 80°±5° | |||

| Cut size tolerance | ±2mm | ±2mm | ||||

| Angle polishing | From 70 ° to 90, angle polishing is possible every 5 ° | |||||

| Longest dimension | 550mm | 400mm | ||||

DB squeegee/DB-R squeegee specifications

| Type | DB squeegee | DB-R squeegee | ||||

|---|---|---|---|---|---|---|

| Hardness | Y60 | B70 | R80 | Y60 | B70 | R80 |

| 60°±5° | 70°±5° | 80°±5° | 60°±5° | 70°±5° | 80°±5° | |

| Cut size tolerance | ±2mm | ±2mm | ||||

| Angle polishing | every 5 ° | Not possible | ||||

| Longest dimension | 1500mm | 1000mm | ||||

Ability of Micro squeegee

A glass epoxy material is used for the core material of the squeegee, and the squeegee has a waist, so a stable attack angle can be maintained. In addition, it is easy to put on and take off because it does not require a squeegee holder.

Create the future of Printable electronics!

The specialized equipment manufacturer for

printing, painting, applying materials and even cutting substrates.

The reason to choose Micro-Tec

“Want to see the happy faces of our customers” is Micro-tec’s belief.

At that belief, provide various electronic component manufacturing equipment such as screen printing machines.

We can also prepare the dryers after printing. We propose wide range of dryer products from belt type to batch type according to your needs.

We have achieved this by providing consistent services in-house,

from sales staff who are familiar with screen printing and equipment,

to technology, manufacturing and assembly, and after-sales service after delivery.

About Micro-tec service

We customize and propose screen printing machines, MLCC / LTCC related equipment (laminators, cutting machines, terminator, etc.), transport equipment, automatic production lines, drying furnaces, etc. according to the customer’s purpose and application.

And we have many distributors overseas, and provide services from a global perspective.

Need more info ?

Micro-tec Micro squeegee Series

Micro-tec Co., Ltd.

Supplier Information

- Store Name: Micro-tec Co., Ltd.

- Vendor: Micro-tec Co., Ltd.

- Address: 279-0011

Chiba Urayasu 1-5-2 Irifune

- Industrial Machinery, Printing Machine, Screen Printers

Screen printer・MTP-1100 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MTP-1100 series – Micro-tec Co. Ltd.

The MTP-1100 series is a large, versatile screen printer. By adopting a wedge method (same for MT-650 series) for driving the table, smooth operation is possible even with a large size.

The MTP-1100 series is a large, versatile screen printer. By adopting a wedge method (same for MT-650 series) for driving the table, smooth operation is possible even with a large size.

The screen is compatible with 950 to 1100 mm and can be used for printing large areas such as multi-cavity boards.SKU: n/a - Industrial Machinery, Other Machinery & Industrial Equipment

Cutting machine MTC Series – Micro-tec Co. Ltd.

Industrial Machinery, Other Machinery & Industrial EquipmentCutting machine MTC Series – Micro-tec Co. Ltd.

Cut to high quality

Cut ceramic green sheet for electronic components such as MLCC, LTCC, HTCC.

Can cut 0402, 0603 chip.

Easy operation with touch panel and joystick.

Cutting speed improved by 30% (compared to our old model).

No need to replace holder, easy blade replacement.

Options: Blade spill inspection, autofocus, automatic fastmark search.SKU: n/a - Industrial Machinery, Printing Machine, Screen Printers

Screen printer・MT-650 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MT-650 series – Micro-tec Co. Ltd.

The MT-650 series is a small to medium-sized multipurpose screen printer. Vibration during printing is reduced by adopting a steel belt for the squeegee head driving unit.

The MT-650 series is a small to medium-sized multipurpose screen printer. Vibration during printing is reduced by adopting a steel belt for the squeegee head driving unit.

SKU: n/a - Industrial Machinery, Printing Machine, Screen Printers

Screen printer・MT-320 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MT-320 series – Micro-tec Co. Ltd.

The MT-320 series is a compact, versatile screen printer.High rigidity is achieved by setting four guide shafts on a highly rigid cast bed and fixing the printing frame.

The MT-320 series is a compact, versatile screen printer.High rigidity is achieved by setting four guide shafts on a highly rigid cast bed and fixing the printing frame.

SKU: n/a - Industrial Machinery, Printing Machine, Screen Printers

Screen printer・MTP-850 series – Micro-tec Co. Ltd.

Industrial Machinery, Printing Machine, Screen PrintersScreen printer・MTP-850 series – Micro-tec Co. Ltd.

The rigidness of the larger machines such as MTP-1100 has been inherited and the operability has also been improved pursuing better printability on film devices and so forth.

MT-850 is a medium-sized stand-alone screen printer with approx. 450mm x 450mm printable area maximum. The rigidness of the larger machines such as MTP-1100 has been inherited and the operability has also been improved pursuing better printability on film devices and so forth.

SKU: n/a

-300x300.png)