Centrifugal Mixing Device without blades C-Mix – AQUATECHS Co.Ltd.

Agitation is from propeller to centrifugal force!

The C-Mix centrifugal agitator overturns the conventional wisdom of agitation by generating flow by centrifugal force.

No blades for safety! Safe because it has no blades!

Mixes well with three-dimensional agitation flow! No whirlpools on the liquid surface and no bubbles!

Choice of sizes (φ19 ~ 400)!

Choice of materials (sus316, aluminum, resin)!

Report Abuse

Stirring System

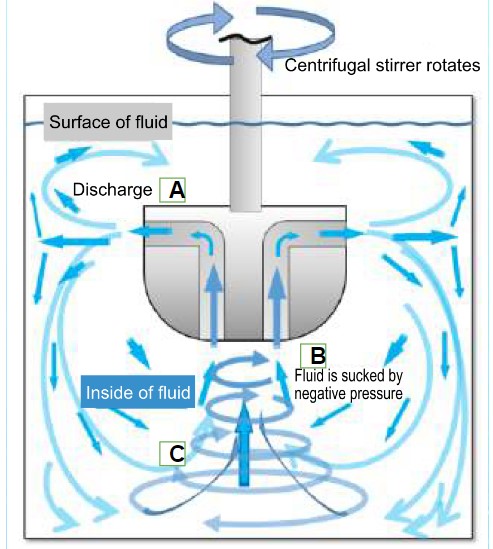

1. Centrifugal force acts at discharge port by rotating stirrer.

2. Fluid in flow channel of stirrer is discharged from port (A) by the centrifugal force. Centrifugal stirrer rotates Surface of fluid Discharge.

3. By sucking fluid from port (B), tornado-like swirling current (C) is generated to spread stirring flow to all direction.

4. “Push and Pull” current makes highly efficient stirring by cooperating of discharge and suction force. Inside of fluid, fluid is sucked by negative pressure.

5. Pulse transmitted from stirrer helps flow spread to all corners and shielded sections.

*Eddy Plus Co., Ltd. is the patentee of C-Mix

(No. 4418019).

Features

Low shearing

With stirring with feathers up to now while mixing liquids, C-Mix stirs by centrifugal force. Therefore, because shear force is small, it is suitable for stirring liquid which prevents deterioration (oxidation) of liquid and mix without breaking. In addition, stirring of “emulsification” or “crushing” can be used for preventing separation after emulsification and for preventing precipitation after crushing.

The frictional heat is small and the temperature rise of the liquid can be suppressed.

Shear: A force acts parallel to any surface inside the object or fluid, such as cutting with a kind of scissors

Safety

Since there is no protrusion, it is safe for contact during rotation.

It can be carried out with confidence in maintenance.

Siphoning

It is best suited for uniform stirring and anti-settling stirring of liquids which have a difference in specific gravity from sucking up liquid from the prepared hole.

In the case of propeller, although it takes time to mix the flow at the bottom of the container, the C – Mix can be stirred in a short time because it sucks directly.

It is difficult to vortex (vortex) at the liquid level, and the liquid level at the time of stirring is quiet.

It also prevents cavitation (cavitation phenomena, bubbles).

No bubbling

Foaming is extremely few, and it is effective for processing such as de-foaming , so it scarcely scatters liquid and it leads to improvement of working environment.

Because the shear force is small, cavitation (bubbles) in the liquid can be suppressed.

VIDEO

Supplier Information

- Store Name: AQUATECHS Co.,Ltd.

- Vendor: AQUATECHS Co.,Ltd.

- Address:

- Food & Beverage Machinery, Mixing Equipment

Electric motor Integrated type C-Mix – AQUATECHS Co.Ltd.

Active in Various Scenes! Versatile electric stirrer!

Mixes well without blades! The centrifugal agitator C-Mix overturns the common sense of agitation.

The world’s first! Electric handheld type with “C-Mix” centrifugal agitator without blades!

Electric handheld type agitator with blade-less centrifugal agitator “C-Mix”!SKU: n/a - Food & Beverage Machinery, Mixing Equipment

Handy Type with C-Mix Pneumatic Agitator – AQUATECHS Co.Ltd.

Food & Beverage Machinery, Mixing EquipmentHandy Type with C-Mix Pneumatic Agitator – AQUATECHS Co.Ltd.

No foaming, no air entrapment! Stirring is possible in every corner of the container!

Mixes well without blades! The centrifugal agitator C-MIX overturns common sense of agitation.

Since it has no blades, it does not damage the container even if it comes in contact with the container wall.SKU: n/a