Actuator LHT – SUZUKI SEIKI CO.LTD.

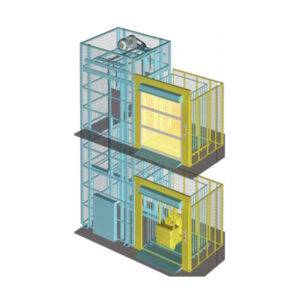

Introducing the LHT Actuator: A medium-sized, high-speed vertical conveyor for the manufacturing industry. With a maximum load capacity of 1.5t and a top speed of 40m/min, it features a groundbreaking function that allows workpieces to be loaded and unloaded from all directions. Equipped with accident prevention facilities and various abnormality detection devices, this lift is designed to ensure safety and protect both the cargo and the machine.

Introducing the LHT Actuator, a medium-sized vertical automatic conveyor designed for medium-weight and high-speed applications in the manufacturing industry. It is capable of handling a maximum load of 1.5 tons and reaching speeds of up to 40m/min, with a carrier size of up to 4 sqm. Equipped with innovative features, it allows workpieces to be loaded and unloaded from both sides and front and back.

The LHT Actuator is a cost-effective and quick-to-install lifter and vertical conveyor, exempt from building standards regulations. It features accident prevention facilities, such as a load detection device, a user-friendly control panel with an emergency button, audible alerts during startup and in case of abnormalities, and optional signal display and light display for real-time monitoring of operation, full capacity, and faults. Additionally, it incorporates various abnormality detection devices for protecting the cargo and the machine by forcibly stopping it when detecting abnormalities. Different specifications may apply for pallet conveyance.

Please note that the above information is a summary of the product description and safety features of the Actuator LHT.

Report Abuse

Product Title: LHT | Actuator

Product Description:

The LHT Actuator is a medium-sized vertical automatic conveyor with a maximum load capacity of 1.5 tons and a top speed of 40 m/min. It is designed for medium-duty and high-speed applications, and can be loaded and unloaded from both sides and front and back, thanks to its innovative functionality.

This lift, or vertical conveyor, is exempt from building regulations, making it more cost-effective and quicker to install than freight elevators. It has a maximum work size of 4 square meters.

Product Features:

– Accident prevention equipment: The LHT Actuator can be equipped with a load shape detection device. The operating panel, with an emergency button, is user-friendly and simple to operate, and also features a buzzer for attention and warning signals during startup and in case of abnormalities. Optional signal display and electric display can be installed to provide real-time monitoring of operation, full load, and abnormalities.

– Various abnormality detection devices: The Actuator is equipped with safety devices to forcibly stop the machine and protect the cargo and the equipment in case of various abnormalities. The specifications of these safety devices may vary for pallet conveyance.

Please note that the above information is subject to change without notice.

POLELIFT IS THE SOLUTION!

SOLUTION 1

Legal compliance and safety issues

SOLUTION 2

Layout and placement issues

SOLUTION 3

Business Efficiency Issues

SOLUTION 4

Cost and performance issues

| Use Cases | |

|---|---|

| Product Type |

Supplier Information

- Store Name: SUZUKI SEIKI CO,.LTD.

- Vendor: SUZUKI SEIKI CO,.LTD.

- Address: Shizuoka 436-0222 2428-1 Shimodaruki

Kakegawa

- Conveyor, Industrial Machinery, Vertical Conveyor

Actuator KHT – SUZUKI SEIKI CO.LTD.

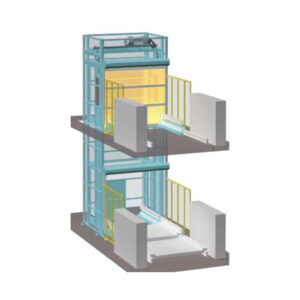

High-capacity and high-speed vertical automated conveyor capable of handling up to 2 tons with a maximum speed of 40m/min. Suitable for C-type (same direction) and Z-type (front and rear direction) work loading and unloading. Equipped with safety features such as load detection device, easy-to-use control panel with emergency button, audible warnings, and real-time status monitoring options. Ensures protection and safety during continuous transportation.

Introducing the “Actuator KHT,” a heavy-duty and high-speed large vertical automatic conveyor in the manufacturing industry.

Product Title: KHT | Actuator

Product Features:

– Capable of handling a maximum load of two tons and reaching a top speed of 40m/min. The “carrier size” is large, with a maximum of six square meters.

– Allows for work placement and retrieval in the C-type (same direction) and Z-type (front and back direction) configurations.This product is a cost-effective and quick-to-install lifter/vertical conveyor that is exempt from applicable building regulations, making it more affordable and with a shorter construction period compared to freight elevators.

Product Highlights:

– Accident prevention equipment: Can be equipped with a cargo shape detection device. The operation panel, with an emergency button, is user-friendly and simple to operate. A buzzer provides attention and warnings during start-up and abnormal situations. Real-time monitoring of operational, full capacity, and abnormal conditions can be achieved through optional signal display units and electronic signboards.

– Various abnormality detection devices: This lifter/vertical conveyor, exempt from applicable building regulations, includes safety devices to forcibly stop the machine and protect the cargo and the equipment itself when detecting various abnormalities.Please note that the provided translation is a summary of the requested product description and may require proofreading or further editing for accuracy.

SKU: n/a - Conveyor, Industrial Machinery, Vertical Conveyor

Trailer Lifter TWD – SUZUKI SEIKI CO.LTD.

A new type of vertical conveyor that is perfect for conventional simple lift needs. Absolutely safe lifter where cargo handling is done on the floor. No need for a pit, allowing loading with carts, cargo trolleys, and hand lifts. Excellent layout performance with easy access from the side. Equipped with a foldable gate on the safety fence outer door for safe use. Easy installation in existing buildings as no machine room is required. No need for confirmation application or final inspection unlike elevators. Low running costs with no mandatory inspections. Can be adapted for various special environments such as explosion-proof, stainless steel, and cold-resistant specifications. Achieves functionality with two motors, providing energy efficiency and affordability. Can transport a 1,000kg load on a tray measuring 1,500mm (width) x 1,600mm (depth). Flexible layout capability with side loading and unloading of trays. Not subject to the Building Standards Act as it is classified as a vertical conveyor.

Introducing the “Trailer Lifter TWD”, a new type of vertical conveyor that is ideal for traditional lifting needs. This absolutely safe lifter allows for floor-level handling of cargo, eliminating the need for a pit. With outstanding layout performance, it can accommodate loading with carts, cargo trolleys, and hand lifts. The Trailer Lifter is equipped with a foldable gate on the safety barrier outer door, ensuring safe operation. Unlike elevators, this vertical conveyor does not require a machine room, making installation in existing buildings easy and exempt from building regulations and inspections. It offers low running costs with no mandatory inspections, and periodic maintenance can be arranged with the manufacturer. Additionally, it can be adapted to various special environments such as explosion-proof, stainless steel, and cold-resistant specifications. With its energy-efficient and cost-effective dual motor system, it can handle a maximum load of 1,000kg on a tray measuring 1,500mm (width) x 1,600mm (depth). The Trailer Lifter also boasts flexible layout capabilities, allowing for lateral loading and unloading of trays.

SKU: n/a - Conveyor, Industrial Machinery, Roller Conveyor

Roller Conveyors – SUZUKI SEIKI CO.LTD.

Standardize pallet conveyance with a wide range of options including roller and chain conveyors. Features include minimal rotation deviation, scratch-resistant surface, and flexible sensor positioning for easy adaptation to changing cargo.

Introducing the Roller Conveyor, a standardized solution for pallet transport. Our extensive lineup includes Roller Conveyors and Chain Conveyors.

– Roller Conveyor I

– Roller Conveyor IIProduct Features:

– POINT 1: Our rollers are specifically designed to minimize rotational deviation.

– POINT 2: The surface is coated with a durable and scratch-resistant paint.

– POINT 3: The sensor can be easily mounted in a free position, allowing for easy adaptation to changes in cargo configurations.For more information, please visit our website.

SKU: n/a - Chain Conveyor, Conveyor, Industrial Machinery

Chain Conveyor – SUZUKI SEIKI CO.LTD.

Durable and low-maintenance conveyor systems with a wide range of options. Featuring a tough and scratch-resistant surface, our chain conveyors are designed for easy sensor installation and adaptability to changing cargo configurations.

Introducing our chain conveyors for the manufacturing industry. Our product line includes U-frame chain conveyors, aluminum frame chain conveyors, and multi-chain conveyors.

Key Features:

– Engineered for durability and ease of maintenance, based on years of expertise.

– Boasts a hard and scratch-resistant baked-on paint surface.

– Sensor mounting positions are adjustable, allowing for easy adaptation to changes in cargo configuration.These chain conveyors are perfect for standardizing pallet transport. With a wide range of options available, we provide solutions tailored to your specific needs. Rely on our expertise to deliver dependable and efficient conveyor systems for your manufacturing operations.

SKU: n/a - Conveyor, Industrial Machinery, Vertical Conveyor

Trailer Lifter TWM – SUZUKI SEIKI CO.LTD.

Effortlessly handle heavy and bulky loads with our innovative vertical lift system. Safe, reliable, and exempt from building regulations, our lift allows for easy loading and unloading without the need for a pit. Customize your layout with our versatile C and Z options. Enhance safety with foldable gates and enjoy low maintenance costs. We also offer specialized models for hazardous or extreme environments.

Introducing the “TWM Tray Lifter,” a product in the manufacturing industry that enables the horizontal loading and unloading of heavy and large capacity items.

Key Features:

– A safe lifter that does not fall under the regulations of the Building Standards Law, as the cargo handling is done on the floor.

– Capable of transporting a load of 2,000kg with a tray size of 2,500mm (width) x 2,500mm (depth).

– This vertical lifting machine, categorized as a tray lifter, is exempt from the Building Standards Law.

– It is a super low-floor type that can be used without a pit, allowing for loading with carts, cargo trolleys, and hand lifts.

– Exceptional layout performance with options for C-type and Z-type arrangements.

– Equipped with a folding gate on the safety fence outer door for secure usage.

– Unlike elevators, no confirmation application or final inspection is required for installation in existing buildings.

– No mandatory inspections, resulting in lower running costs.

– Regular inspections will be conducted by our company based on the contract.

– We can produce products that are suitable for special environments such as explosion-proof, stainless steel, and cold-resistant specifications.SKU: n/a - Conveyor, Industrial Machinery, Vertical Conveyor

Trailer Lifter TWX – SUZUKI SEIKI CO.LTD.

Highly efficient and absolutely safe vertical conveyor with improved handling capacity, offering cost-effective and quick installation. Exempt from building regulations, this innovative lift is perfect for various environments and eliminates the need for inspections, reducing running costs.

Introducing the “Tray Lifter TWX,” a product in the manufacturing industry, this innovative vertical conveyor system achieves high transport capacity by circulating trays. Compared to traditional tray lifters, it offers improved transport capability and is completely safe, as it allows for handling of goods on the floor, exempting it from compliance with building regulations. The TWX is a cost-effective and quick-to-install vertical conveyor system that is not subject to building regulations, making it an ideal alternative to cargo elevators. With its unique features, such as the ability to operate without a pit and easy installation in existing buildings, the TWX offers a safe and efficient solution for vertical transportation needs, while also not requiring approval or inspections, resulting in lower running costs. We also provide specialized versions, including explosion-proof, stainless steel, and cold-resistant models, to meet specific environmental requirements.

SKU: n/a