THINKY Mixer Vacuum type ARV-310P – THINKY CORPORATION

Standard vacuum mixer enabling uniform mixing and elimination of submicron-level air bubbles.

・Simultaneous mixing, dispersion, and submicron-level air bubble elimination

・Deaeration of high-viscosity materials difficult to be processed by a centrifugal separator

・Reduced processing time and improved deareation performance compared to the atmospheric type mixer

・Centrifugal force of revolution prevents overflow of material during operation

・High-specific-weight materials such as fluorescent material can be evenly dispersed and deaerated without sedimentation (ARV-310LED)

・CE certified model is available

Report Abuse

Features

Touch panel

Register up to 20 recipes, each specified by an appropriate name.

Real-time display and check of recipe progress and operating status

Easy identification of causes of error by clear display of error status

with a corresponding explanation

Communication function

An external terminal for recipe selection and loading as well as operation start and stop available

During remote control, external terminal instructions are prioritized and main unit panel

operation is disabled.

Supports equipment function of reporting progress and operating status every second

Sample software for remote operation available free of charge (for Windows 7, 8, and 10)

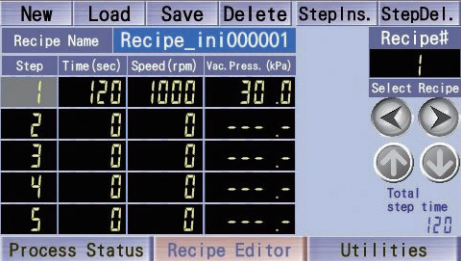

Operation screen of touch panel

Initial screen

Japanese ⇄ English language switch possible

Screen of operation control

Displays real-time revolution speed and vacuum pressure

Screen of utility selection

Shows total number of operations and total operation time in a table

Screen for editing recipe

Viewing and editing of all steps in one screen possible

Screen for recipe-name input

Upper and lower case letters and numerals can be input.

Example of alarm display

Error details, explanation of cause, and recommended action are displayed together with the error number.

Specification

| Unit Dimensions/ Unit weight | H450×W555×D645(mm)Approx. 90kg |

|---|---|

| Maximum Capacity*1 *1:Total mass to mount on the cup holder, including materials, containers, and adapters. | 310g |

| Standard Container*2 *2:Contact us because the actual volume of mixing may vary depending on the containers, materials, and conditions. | 300 ml resin container |

| Power Supply | Voltage: Single-phaseAC 100 V ± 10 %, 50/60 HzPower consumption:Approx. 50 VA (standby)Max 1200 VA (operation) |

| Accessories | Instruction Manual × 1,AC cable (including 3P adapter) × 1,HDPE 300 ml container × 3 (Inner lid with hole×3, Outer lid with hole × 3)150 ml Container × 1 (Inner lid with hole × 1, Outer lid with hole × 1, Adapter × 1, and 1 spare rubber ring)Box wrench × 1, Hexagon wrench × 1,Pliers × 1,Vacuum pump oil,Waste oil receiver × 1,Funnel × 1 |

Video

For agitators and de-aerators, THINKY is the best choice.

Since its foundation in 1970, THINKY Corporation has been developing and introducing new technologies that had never existed before, under the theme of “”manufacturing products that create excitement and inspiration. Some of our products were the first of their kind in Japan and the first in the world.

Today, the world’s first “”rotation/revolution mixer,”” which THINKY released as a practical machine, is used in research and development fields around the world and has exerted its influence on global manufacturing as the de facto standard mixer in the field of advanced materials.

We will continue to take on the challenge of developing products that can lead the world with the themes of “”originality,”” “”manufacturing,”” and “”excitement and inspiration. That is THINKY .

Address

2-16-2, Sotokanda, Chiyoda-ku, Tokyo, 101-0021,Japan

The five key reasons why Thinky is a popular choice among many users are as follows:

World-Class Performance and Quality

As a pioneer in high-performance mixers, Thinky offers innovative products using its unique “revolution and rotation” method. These products enable simultaneous stirring and defoaming, contributing significantly to industries such as LED, LCD, adhesives, paints, pharmaceuticals, semiconductors, and batteries.

Customization Capability

Thinky’s products deliver high-quality processing even with standard specifications but can also be customized to suit advanced materials’ specific characteristics and objectives. This approach ensures maintained compatibility with environmental conditions, durability, and stability while meeting user demands.

Extensive Application Know-How

With a sales record in over 56 countries, Thinky mixers demonstrate their prowess in cutting-edge material development. They have more than 2000 domestic patent applications, leading technological innovation through alliances with researchers and experts.

Global Implementation Record

Thinky products have been implemented in over 56 countries with more than 47,000 units, establishing them as a global standard. This extensive adoption underscores their importance in research and development and material development sectors.

Comprehensive Support System

Thinky offers a support system that goes beyond maintenance and repair, providing long-term technical support. With a structure supporting over 20 years of product use, Thinky ensures consistent high-quality results through regular maintenance and overhauls. Post-purchase technical support is also robust, aiding users across various materials and conditions.

Need more info ?

Meeting traceability needs in operating processes THINKY Mixer Vacuum type ARV-310P

THINKY CORPORATION

Supplier Information

- Store Name: THINKY CORPORATION

- Vendor: THINKY CORPORATION

- Address: Tokyo

- Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing Equipment

THINKY MIXER ARE-501(Non Vacuum) – THINKY CORPORATION

Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing EquipmentTHINKY MIXER ARE-501(Non Vacuum) – THINKY CORPORATION

A higher functionalities model of ARE-500. Medium-size, general-purpose model supporting upscale to a maximum of 500ml capacity and production.

・It supports upgrading from smaller models.

・The high-durability drive system is suitable for production.

・A maximum of 500ml or 1.1kg of material can be simultaneously mixed and deaerated.

・A wide range of adapters extend the variations of containers that can be used (syringes, barrels, and disposable containers).

・The cold-insulated, heat-resistant adapter supports various characteristics of materials.

・Memory and step-operation functions enable control of operating conditions.SKU: n/a - Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing Equipment

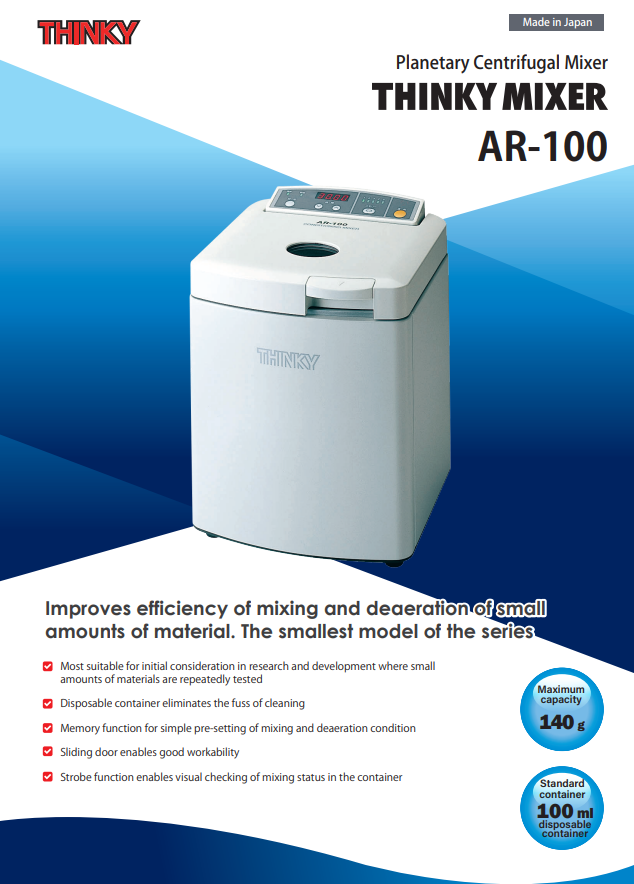

THINKY MIXER AR-100(Non Vacuum) – THINKY CORPORATION

Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing EquipmentTHINKY MIXER AR-100(Non Vacuum) – THINKY CORPORATION

Improves efficiency of mixing and deaeration of small amounts of material. The smallest model of the series

・Ideal for initial research and development where small amounts of materials are tested repeatedly

・The disposable container eliminates the need for cleaning

・The memory function allows for easy pre-setting of mixing and deaeration conditions

・The sliding door provides excellent workability

・The strobe function allows for visual inspection of the mixing status in the containerSKU: n/a - Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing Equipment

THINKY MIXER ARE-310(Non Vacuum) – THINKY CORPORATION

Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing EquipmentTHINKY MIXER ARE-310(Non Vacuum) – THINKY CORPORATION

The standard model of the non-vacuum THINKY MIXER series.

・It supports a broad range of materials, including high-viscosity materials and nano fillers.

・The two modes of mixing and deaeration enable the dispersion and deaeration of high-viscosity materials in a short amount of time.

・The cold-insulated, heat-resistant adapter allows for the support of various material characteristics.

・There is a wide variety of adapters for using various containers.

・It has memory and step-operation functions for controlling and executing operating conditions.

・It has a unique air-cooling system.SKU: n/a - Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing Equipment

THINKY MIXER ARE-250 CE(Non Vacuum) – THINKY CORPORATION

Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing EquipmentTHINKY MIXER ARE-250 CE(Non Vacuum) – THINKY CORPORATION

Improves the efficiency of mixing and degassing small amounts of material. Best seller in CE Certified Mixer.

・This 230V-ready device

・The two modes of mixing and deaeration enable the dispersion and deaeration of high-viscosity materials in a short amount of time

・The cold-insulated, heat-resistant adapter supports various material characteristics

・A wide variety of adapters are available for use with various containers

・Memory and step-operation functions allow for the control and execution of operating conditions

・A CE-certified model is available.SKU: n/a - Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing Equipment

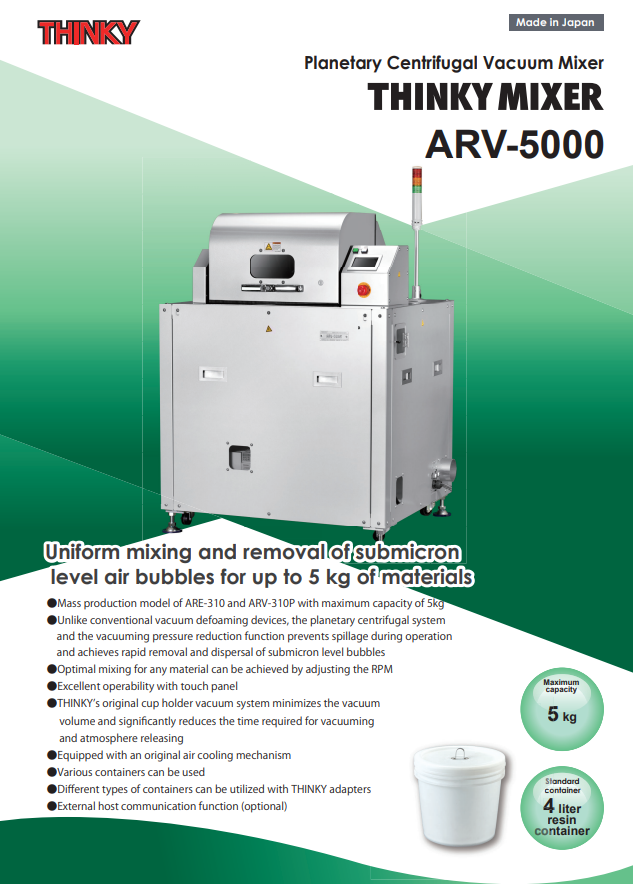

Planetary Centrifugal Vacuum Mixer THINKY Mixer ARV-5000 – THINKY CORPORATION

Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing EquipmentPlanetary Centrifugal Vacuum Mixer THINKY Mixer ARV-5000 – THINKY CORPORATION

Large model that handles large capacity of maximum 3L and achieves deaeration at the submicron level

・Large capacity of 3L・5kg.

・No spillage over of materials during operation because the optimal recipe for material can be set.

・Optimal setting according to materials is possible by changing the number of rotations.

・Excellent operability with a touch panel.

・Equipped with cooling function by rotation

・Various containers are supportedSKU: n/a - Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing Equipment

Vacuum Syringe Charger ARC-40H – THINKY CORPORATION

Chemical & Pharmaceutical Machinery, Industrial Machinery, Mixing EquipmentVacuum Syringe Charger ARC-40H – THINKY CORPORATION

High efficiency of material charging for small volume syringes

・Able to charge materials into 3ml, 5ml and 10ml syringes, which are too small to charge manually.

・Up to 4 syringes can be charged at one time effectively.

・Capable for materials from low to high viscosity.

・The process from mixing and defoaming to charging is integrated by THINKY products.

・Easy to cleanSKU: n/a