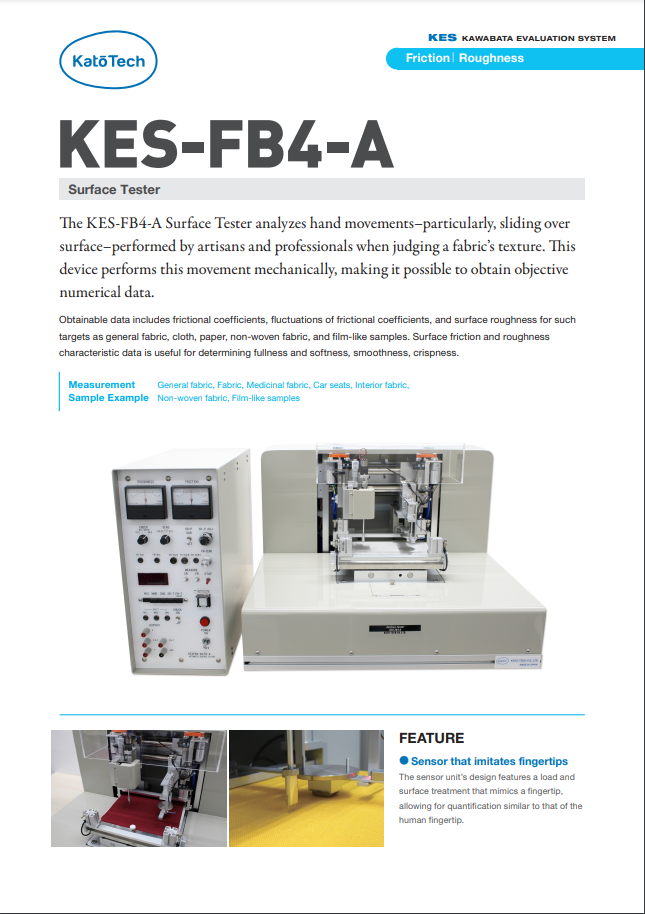

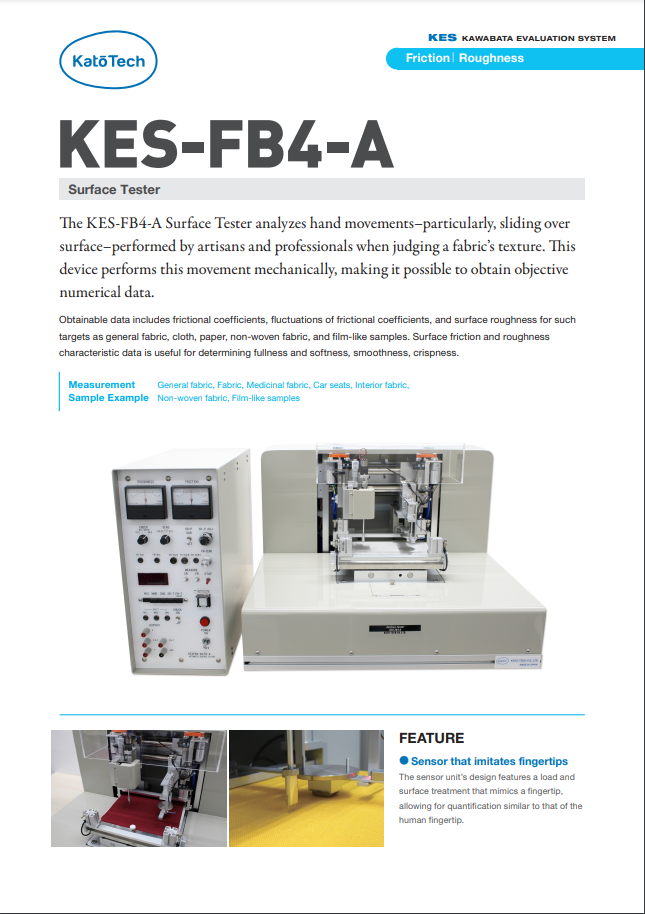

Surface Tester KES-FB4-A – KATO TECH CO.LTD.

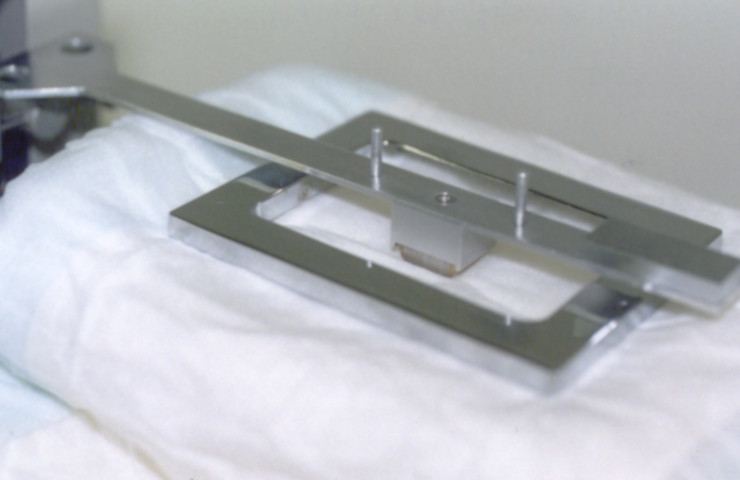

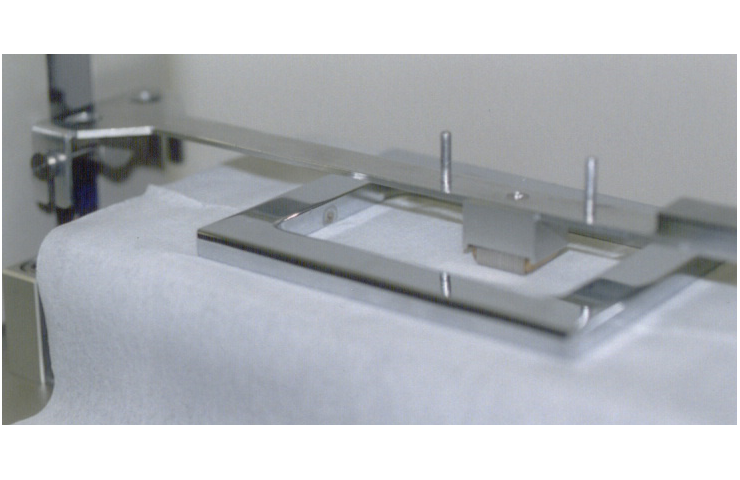

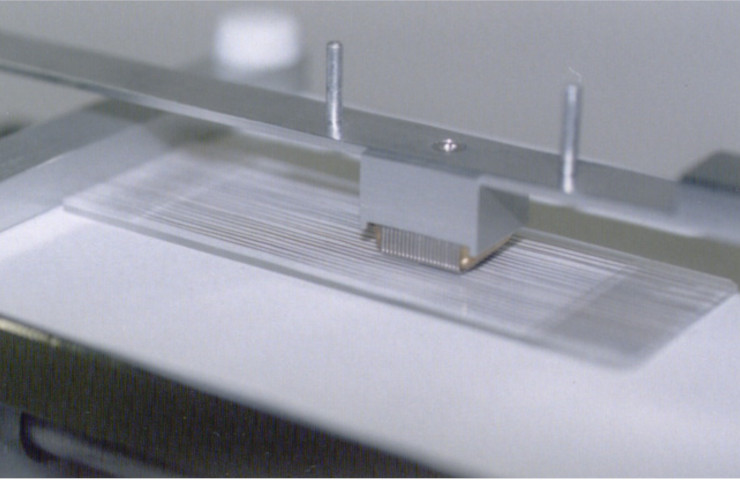

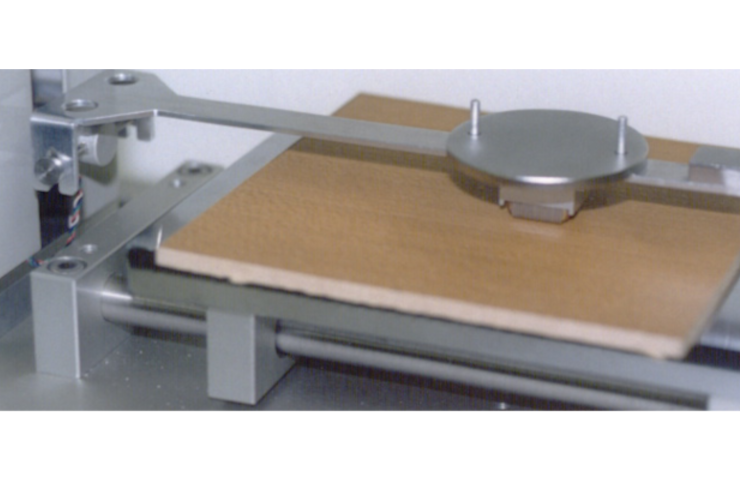

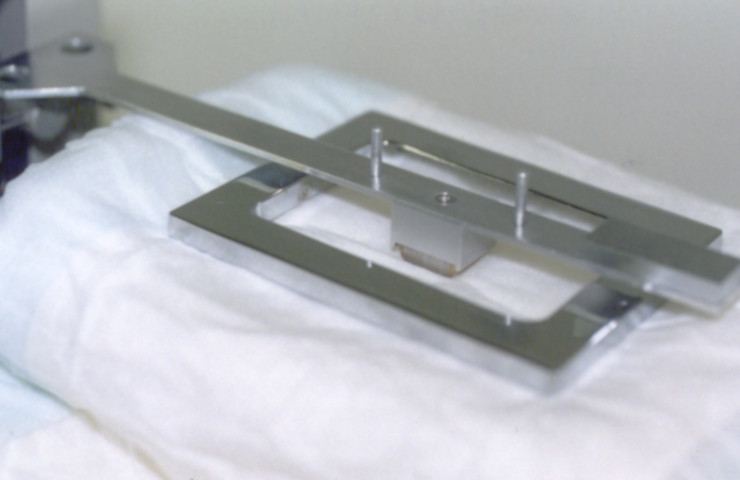

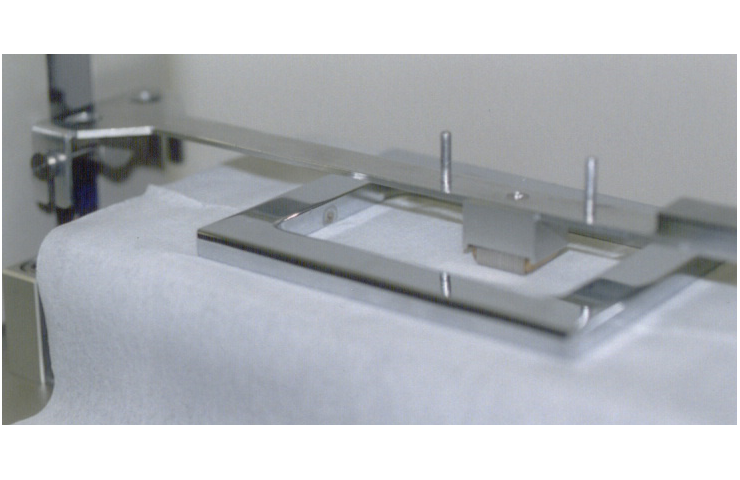

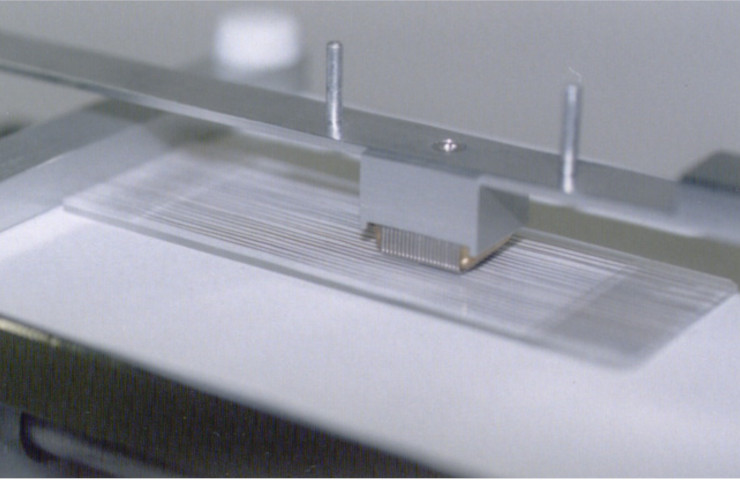

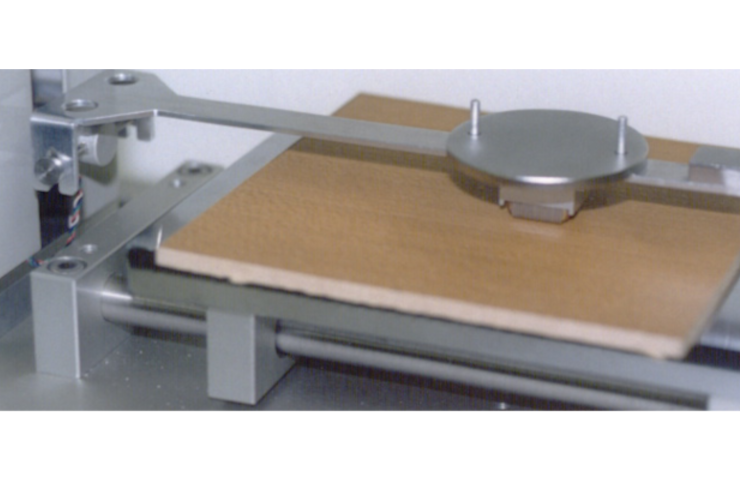

The KES-FB4-A Surface Tester analyzes finger movements-particularly, strokes-performed by artisans and professionals when judging a fabric’s texture.

Obtainable data includes frictional coefficients, fluctuations of frictional coefficients, and surface roughness for such targets as general fabric, cloth, paper, non-woven fabric, and film. Surface friction and roughness characteristic data is useful for determining fullness and softness, smoothness, crispness.

Report Abuse

Features

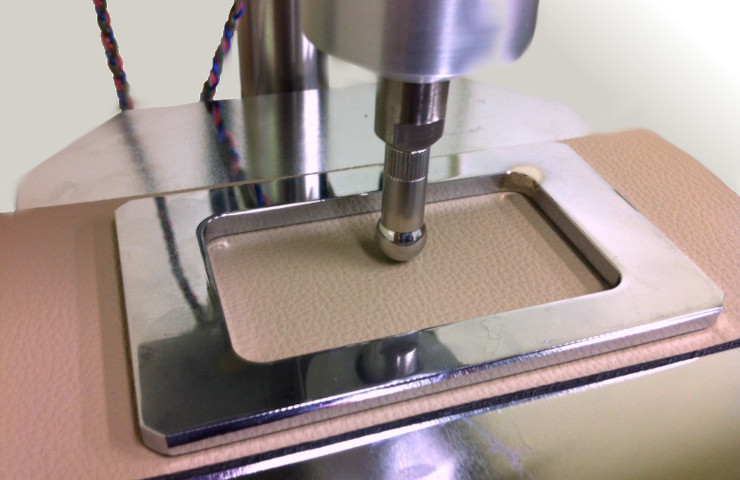

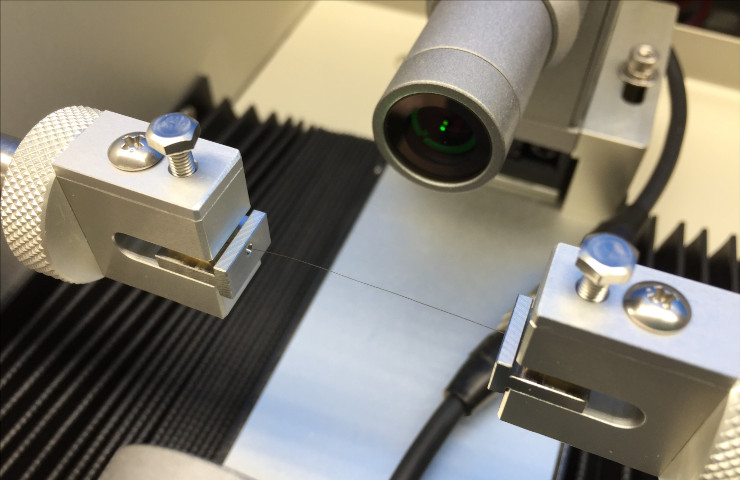

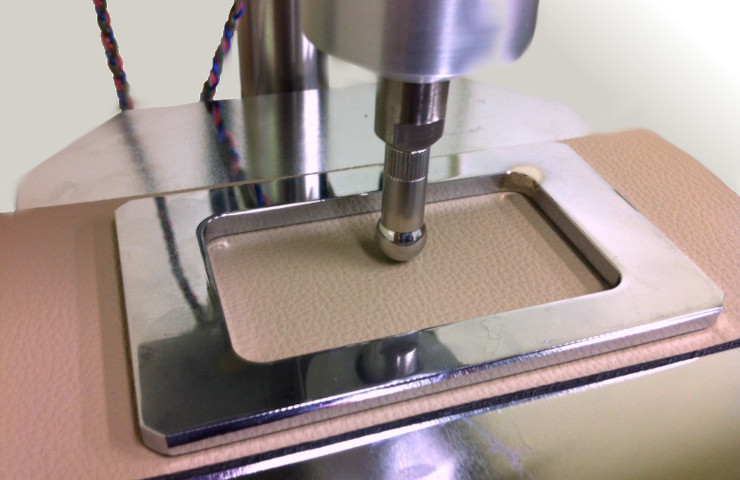

Sensor that imitates fingertips

The sensor unit’s design features a load and surface treatment that mimics a fingertip, allowing for quantification similar to that of the human fingertip.

Example of Measurement Samples- Textile

- Resin

- Non-woven fabric

- Paper

- Coating

- Leather/Synthetic leather (Car seats)

- Film

System Configuration Diagram

Case Studies of This Product

- Comfort evaluation of shirts

- Comfort evaluation of socks

- Evaluation of mask’s texture

From Creating the Global Standard in Tactile Sensation with Texture Testing Machines to Custom Machine Design.

Since proposing the concept of texture measurement in 1968, Kato Tech has been responding to global needs, primarily in the textile industry.

We have now grown into an electronic measuring instrument manufacturer with connections in approximately 50 countries, serving various industries including automotive, papermaking, and cosmetics.

In addition, to contribute to diverse research, development, and societal progress, we are committed to producing custom-made large industrial machinery that materializes our customers’ specific requirements.

Enhancing Product Quality with High-Precision Testers: From Tactile Comfort Evaluation to Custom Machine Designs, Passing Down the Art of Expert Craftsmanship!

Kato Tech was established in Kyoto in 1961. We are celebrating our 62nd year in business.

We specialize in manufacturing and selling testing machines that quantitatively measure the “tactile comfort” when touching objects. In 1964, our collaboration with Dr. Kawabata from Kyoto University led to the successful development of technology known as “KES” (Kawabata Evaluation System).

The KES technology correlates with sensory evaluation by seasoned experts and converts measured data into objective numerical values. This remarkable technology has gained global recognition.

We measure and evaluate “texture, tactile sensation, and comfort” in various industries, including textiles, cosmetics, food products, batteries, automobile interior materials, and instrument panels.

We are committed to measuring and enhancing the “tactile comfort” of diverse products and making the artisans’ expertise available to everyone.

Business Outline

1. Electronic measuring instruments

2. Polymer material-related instruments

3. Various kinds of manufacturing instruments

4. Large Special Industrial Machinery

From texture testers creating “global standards for texture” to custom-made machinery design

Since we proposed the concept of Texture Measurement, Kato Tech has been meeting

the customer demands mainly in the textile industry.

Over the past two decades, we have grown as an electronic measuring instruments

manufacturer and have connections with over 50 countries in various industries, such as

automobile, paper and cosmetics, etc.

Additionally, we are working on the production of custom-made large industrial machinery to satisfy our customers’ demands and contribute to their various R&D and social development activities.

What is Texture Measurement That Quantifies Texture?

“Texture” has long been referred to as the material texture and tactile sensation – what people feel when they touch an object. However, it is only a subjective evaluation.

“KES” is technology for quantifying subjective evaluations by using measurement data, which is obtained by reproducing artisans’ hand movements and sensitivity when they distinguish the texture.

This technology was jointly developed with Dr. Kawabata of Kyoto University and it has been playing an important role in quality development.

SAMPLING SERVICE

We provide free sampling services “for a comprehensive understanding of our products,” “confirmation of obtainable measured data,” and “preparation of the necessary data for internal approval documents.” Please don’t hesitate to contact us.

What is Texture Measurement?

Texture measurement is a technique that transforms subjective tactile sensations into objective data.

The sense of touch people experience when handling materials, traditionally referred to as “texture”, has historically been judged subjectively by craftsmen and experts.

Texture measurement replicates actions like stroking, stretching, bending, and pressing on sophisticated testing equipment, converting ambiguous physical properties assessments into shared, objective numerical data.

This technology not only pursues comfort but also helps in preserving and passing down skilled artisans’ techniques to future generations.

Texture Measurement and KES (KAWABATA EVALUATION SYSTEM)

Developed in 1970 by Dr. Kiyoshi Kawabata and Dr. Masako Niwa, KES successfully transformed subjective tactile judgments into objective data.

Short for “KAWABATA EVALUATION SYSTEM,” KES is now commonly used in industries ranging from textiles to cosmetics, food, papermaking, and automobiles, serving as a global standard for texture evaluation.

Applications of KES

Initially focused on textile measurement, KES’s versatile texture measurement technology has been applied across diverse industries.

It’s used to evaluate the texture of food, the ergonomics of containers, the feel of cosmetics, the comfort of interiors, and even the touch of coatings, affecting various sectors including environmental and welfare industries. Centered around human experiences, the scope of KES is continually expanding into the future.

Learn about the industries where texture measurement is in demand from case studies.

Fiber

Tactile evaluation of dried laundry

| client | household goods manufacturer |

| Measurement sample | fiber |

| Introductory model | KES-F7 Thermo Labo |

Quantitative evaluation of the dry touch of laundry.

Verified with two types of towels: sunny-dried and room-dried towels.

Measured qmax values and confirmed correlation between wet and dry touch.

Evaluation of contact cold/warmth of cold mattress pad

| client | bedding manufacturer |

| Measurement sample | fiber |

| Introductory model | KES-F7 Thermo Labo |

Evaluated the “coolness” of a cold mattress pad.

Skin sensation of “warmth” or “coldness” when the skin touches the fabric, or contact cold/warmth sensation, was measured.

Evaluation of heat retention of functional innerwear

| client | Textile Product Manufacturer |

| Measurement sample | fiber |

| Introductory model | KES-F7 Thermo Labo |

Compared the warmth of multiple pieces of functional innerwear.

Evaluated the warmth retention of fabrics.

Resin

Texture evaluation of automobile interior materials (instrument panels)

| client | automaker |

| Measurement sample | resin |

| Introductory model | KES-G5 Compression Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester KES-F7 Thermo Labo NT-01 Surface Friction Tester |

Used to evaluate the texture of instrument panels.

Measured softness and smoothness to the touch, and coolness and warmth to the touch.

Evaluation of contact cold/warmth of bathroom floors

| client | Housing equipment manufacturer |

| Measurement sample | resin |

| Introductory model | KES-F7 Thermo Labo |

Evaluated the contact cold/warmth sensation when the feet touch the bathroom floor.

Measured the Qmax value, an index that evaluates the “cold” or “warm” sensation felt when the skin touches the floor.

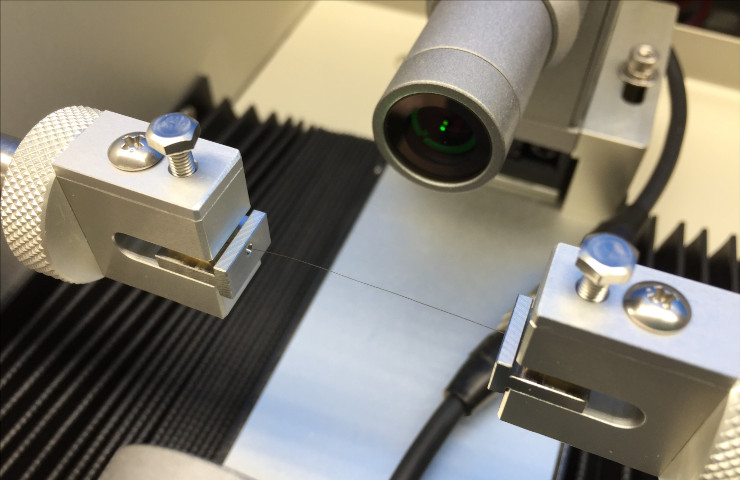

Quality evaluation of medical wires

| client | Medical supply manufacturer |

| Measurement sample | resin |

| Introductory model | KES-SESRU Roughness/Friction Tester |

Used to compare differences in medical wire quality that cannot be determined by touch.

Evaluated for slipperiness, unevenness, and smoothness.

Non-woven Fabric

Quality control of disposable diapers

| client | Non-woven Manufacturer |

| Measurement sample | Non-woven Fabric |

| Introductory model | KES-YN1-B Large-size torsion testing machine KES-G5 Compression Tester KES-SE Friction Tester KES-F8 Air Permeability Tester KDMD-200 Baby Dummy Dolls |

Used for quality control of design.

Measurements of diaper softness, surface smoothness, and hardness when twisted.

Dummy dolls are also used to test urine leakage and diffusion by having a sample actually attached to the doll.

Evaluation of the feel of the mask

| client | hygiene products manufacturer |

| Measurement sample | Non-woven Fabric |

| Introductory model | KES-FB4-A Surface Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester |

Verified the mask’s feel against the skin.

Measured the coefficient of friction and evaluated fluffiness and flexibility.

Tissue texture and breathability evaluation

| client | paper manufacturer |

| Measurement sample | Non-woven Fabric |

| Introductory model | KES-FB4-A Surface Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester KES-F8 Air Permeability Tester |

Evaluates the tissue’s smoothness to the touch and air permeability.

Measured smoothness and roughness to the touch and breathability.

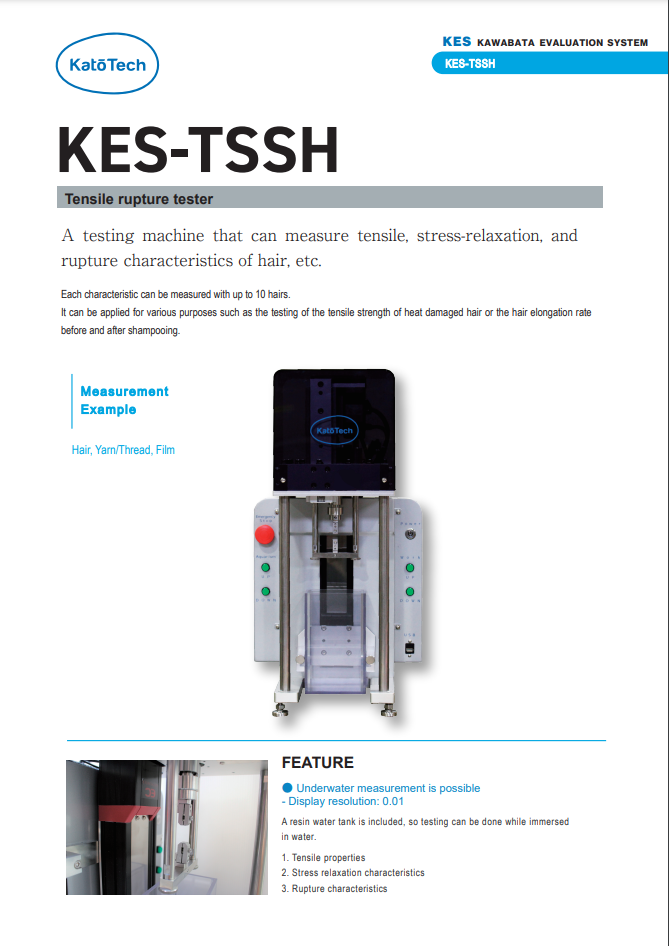

Hair

Evaluates the level of heat damage to the hair

| client | |

| Measurement sample | |

| Introductory model |

Measured tensile strength of hair damaged by heat at G1SH. The damage level is evaluated.

At the time of measurement, hair diameter was measured and cross-sectional area was calculated using SK2000, and hair was grouped so that the average cross-sectional area was equal.

Measurements were performed under the same hair conditions.

Evaluation of bending properties before and after shampoo use

| client | hair care manufacturer |

| Measurement sample | Hair |

| Introductory model | KES-FB2-S Pure Bending Tester KES-FB2-SH Single Fiber Bending Tester |

Evaluation of hair firmness after shampoo and conditioner use

| client | Cosmetics Manufacturer |

| Measurement sample | Hair |

| Introductory model | KES-SE Friction Tester KES-SESRU Roughness/Friction Tester |

Compared the feel of several shampoos and conditioners after use and after drying.

Verified which products left the hair with good finger movement.

Measured the average coefficient of friction of a hair bundle and evaluated the smoothness and firmness of the hair surface.

Leather

Seat comfort evaluation of automobile seats

| client | automaker |

| Measurement sample | Leather |

| Introductory model | KES-G5 Compression Tester |

Used to objectively evaluate the seating comfort of car seats.

Compression characteristics are measured and “softness” and “elasticity” are evaluated.

Seat comfort evaluation of automobile seats

| client | automaker |

| Measurement sample | Leather |

| Introductory model | KES-FB2-L Large bending Tester |

Used to compare genuine leather, synthetic leather, and PVC leather with a sample thickness of 1 mm or greater.

Bending hardness and recovery are measured and leather suppleness is evaluated.

Seat comfort evaluation of automobile seats

| client | automaker |

| Measurement sample | Leather |

| Introductory model | HapLog Wearable Tactile Action Sensor |

Evaluates the operability of the steering wheel.

Measured finger force when gripping the steering wheel and movement during operation.

Other

Paper texture evaluation (softness, roughness)

| client | Universities and Testing Institutes |

| Measurement sample | Paper |

| Introductory model | KES-FB2-A Pure Bending Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester |

Used to evaluate paper texture.

Measure the hardness of the paper when bent and the roughness when touched.

Evaluation of flooring texture and durability

| client | building material manufacturer |

| Measurement sample | Wood |

| Introductory model | KES-SE Friction Tester KES-F7 Thermo Labo KK01 Scratch Tester KK02 Scratch Tester KK03 Scratch Tester |

Evaluated the feel and durability of flooring.

Verified slipperiness, warm/cold sensation, and scratchiness.

Evaluation of coolness after cosmetic application

| client | Cosmetics Manufacturer |

| Measurement sample | Liquid |

| Introductory model | Liquid |

Evaluated the characteristics of heat after cosmetic application.

Analyzed the correlation with sensory evaluation for coolness.

Major Clients of Electronic Measuring Instruments

| Domestic (in alphabetical order) | ・Asahi Kasei Corp. ・ASICS Corporation |

| International (in alphabetical order) | ・Australia ・Canada ・Czech Republic ・France ・Hong Kong ・Italy ・Netherlands ・Portugal ・Spain ・Thailand ・United States ・Brazil |

Industry-industry, industry-government-university collaboration experience

-joint development-

| KYOTO UNIVERSITY | KES Texture Tester |

| THE UNIVERSITY OF SHIGA PREFECTURE | Nanofiber Electrospinning Unit |

| Shiseido Company, Limited | HapLog |

| Toyota Motor Corporation | Dummy Doll (Custom-made for evaluation of sitting comfort of automotive seats) |

| AOKI Inc. | Slacks Robot |

| Keio University | QUANTITEXTURE |

About US

Manufacture of electronic measuring instruments

Texture measurement technology KES provides measurement equipment to evaluate samples

| Company Name | KATO TECH CO.,LTD. |

| Location | 26 Karato-cho, Nishikujo, Minami-ku, Kyoto 601-8447 Japan |

| Representative Director | Atsuko Kato |

| Established | September 1st, 1961 |

| Business Outline | 1. Electronic measuring instruments 2. Polymer material-related instruments 3. Various kinds of manufacturing instruments 4. Large Special Industrial Machinery |

Need more info ?

Surface Tester KES-FB4-A Catalog

KATO TECH CO.,LTD.

Supplier Information

- Store Name: KATO TECH CO.,LTD.

- Vendor: KATO TECH CO.,LTD.

- Address: 601-8447

Kyoto Minami-ku 26, Nishikujo Karado-cho

- Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Friction Tester KES-SE – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentFriction Tester KES-SE – KATO TECH CO.LTD.

The KES-SE Friction Tester analyzes hand movements-particularly, strokes-performed by artisans and professionals when judging a fabric’s texture.

The device performs this movement mechanically, making it possible to obtain objective numerical data while offering more enhanced versatility over the KES-FB4-A Surface Tester.

Obtainable data includes average frictional coefficient, and fluctuation of average frictional coefficient. From these characteristic values, the KES-SE evaluates and quantifies smoothness, slipperiness, and roughness felt when actually touching the target in order to provide objective data.SKU: n/a - Testing Equipment, Testing Instrument & Equipment

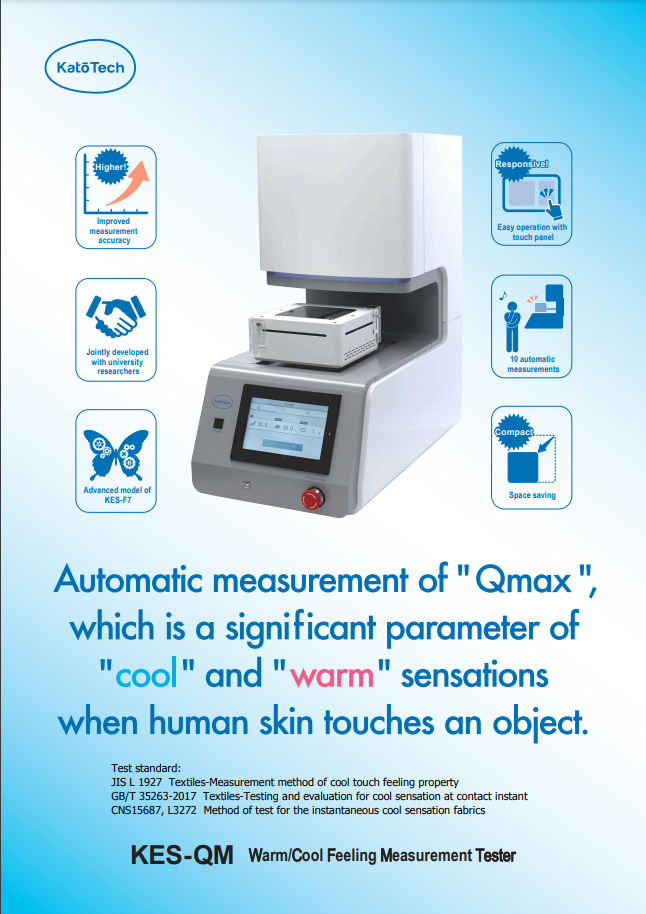

Warm/Cool Feeling Measurement Tester KES-QM – KATO TECH CO.LTD.

Testing Equipment, Testing Instrument & EquipmentWarm/Cool Feeling Measurement Tester KES-QM – KATO TECH CO.LTD.

Automatic measurement of “Qmax”, which is a significant parameter of “cool” and “warm” sensations when human skin touches an object.

The sensation of coldness or warmth when skin touches an object is referred to as the “coldness and warmth feeling.” The feeling of coldness or warmth will vary depending on the amount of heat transferred from the skin to the object. This device measures that feeling automatically by evaluating the “qmax” value (peak heat flux).

SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Compression Tester KES-FB3-A – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentCompression Tester KES-FB3-A – KATO TECH CO.LTD.

Compression characteristic data is useful for determining fullness and softness, smoothness, anti-drape stiffness.

The KES-FB3-A Compression Tester analyzes hand movements-particularly, pushing with a finger-performed by artisans and professionals when judging a fabric’s texture. This device performs this movement mechanically, making it possible to obtain objective numerical data.

Obtainable data includes compression rigidity, compression energy, and recoverability for such targets as general fabric, cloth, paper, and non-woven fabric.SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

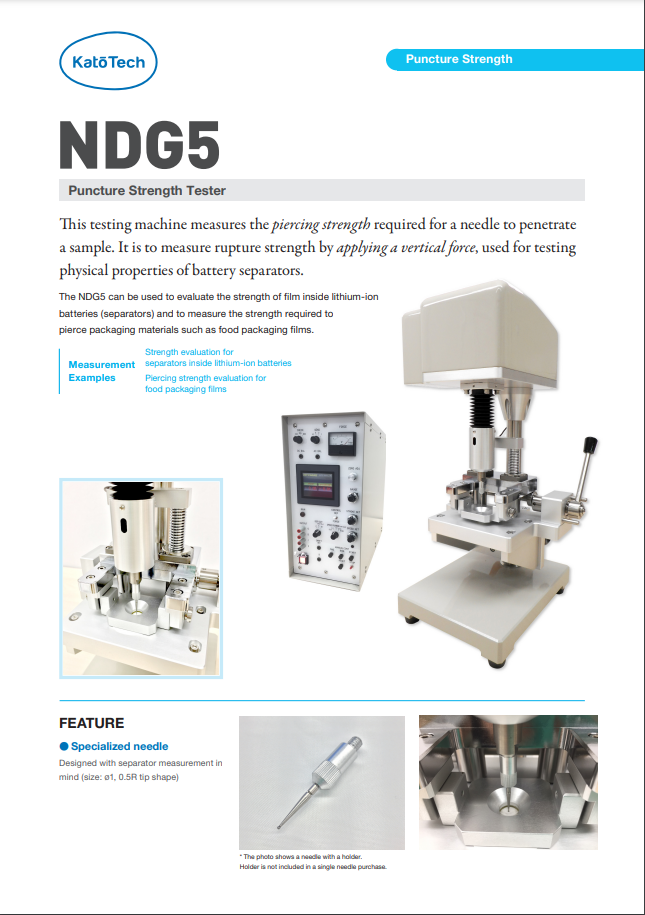

Puncture Strength Tester NDG5 – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentPuncture Strength Tester NDG5 – KATO TECH CO.LTD.

This testing machine measures the piercing strength required for a needle to penetrate a sample.

It is to measure rupture strength by applying force at a right angle, used for testing physical properties of battery separators.

The NDG5 can be used to evaluate the strength of film inside lithium-ion batteries (separators) and to measure the strength required to pierce packaging materials such as food packaging films.SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Compression Tester KES-G5 – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentCompression Tester KES-G5 – KATO TECH CO.LTD.

The KES-G5 Compression Tester analyzes hand movements-particularly, movements by finger-performed by artisans and professionals when judging a fabric’s texture.

Obtainable data includes compression rigidity, compression energy, and recoverability.

The machine can be applied to a wide variety of fields and purposes, including determining the softness of disposable diapers and the hardness of mousse.SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Air Permeability Tester KES-F8 – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentAir Permeability Tester KES-F8 – KATO TECH CO.LTD.

The KES-F8 Air Permeability Tester is designed to quickly and accurately measure the breathability and permeability of a wide range of samples, from those with high permeability, such as stockings, to those with low permeability, such as synthetic leather.

Samples can be mounted in just a few seconds using the handle, and measuring is also incredibly simple.

SKU: n/a

Features

Sensor that imitates fingertips

The sensor unit’s design features a load and surface treatment that mimics a fingertip, allowing for quantification similar to that of the human fingertip.

Example of Measurement Samples- Textile

- Resin

- Non-woven fabric

- Paper

- Coating

- Leather/Synthetic leather (Car seats)

- Film

System Configuration Diagram

Case Studies of This Product

- Comfort evaluation of shirts

- Comfort evaluation of socks

- Evaluation of mask’s texture

From Creating the Global Standard in Tactile Sensation with Texture Testing Machines to Custom Machine Design.

Since proposing the concept of texture measurement in 1968, Kato Tech has been responding to global needs, primarily in the textile industry.

We have now grown into an electronic measuring instrument manufacturer with connections in approximately 50 countries, serving various industries including automotive, papermaking, and cosmetics.

In addition, to contribute to diverse research, development, and societal progress, we are committed to producing custom-made large industrial machinery that materializes our customers’ specific requirements.

Enhancing Product Quality with High-Precision Testers: From Tactile Comfort Evaluation to Custom Machine Designs, Passing Down the Art of Expert Craftsmanship!

Kato Tech was established in Kyoto in 1961. We are celebrating our 62nd year in business.

We specialize in manufacturing and selling testing machines that quantitatively measure the “tactile comfort” when touching objects. In 1964, our collaboration with Dr. Kawabata from Kyoto University led to the successful development of technology known as “KES” (Kawabata Evaluation System).

The KES technology correlates with sensory evaluation by seasoned experts and converts measured data into objective numerical values. This remarkable technology has gained global recognition.

We measure and evaluate “texture, tactile sensation, and comfort” in various industries, including textiles, cosmetics, food products, batteries, automobile interior materials, and instrument panels.

We are committed to measuring and enhancing the “tactile comfort” of diverse products and making the artisans’ expertise available to everyone.

Business Outline

1. Electronic measuring instruments

2. Polymer material-related instruments

3. Various kinds of manufacturing instruments

4. Large Special Industrial Machinery

From texture testers creating “global standards for texture” to custom-made machinery design

Since we proposed the concept of Texture Measurement, Kato Tech has been meeting

the customer demands mainly in the textile industry.

Over the past two decades, we have grown as an electronic measuring instruments

manufacturer and have connections with over 50 countries in various industries, such as

automobile, paper and cosmetics, etc.

Additionally, we are working on the production of custom-made large industrial machinery to satisfy our customers’ demands and contribute to their various R&D and social development activities.

What is Texture Measurement That Quantifies Texture?

“Texture” has long been referred to as the material texture and tactile sensation – what people feel when they touch an object. However, it is only a subjective evaluation.

“KES” is technology for quantifying subjective evaluations by using measurement data, which is obtained by reproducing artisans’ hand movements and sensitivity when they distinguish the texture.

This technology was jointly developed with Dr. Kawabata of Kyoto University and it has been playing an important role in quality development.

SAMPLING SERVICE

We provide free sampling services “for a comprehensive understanding of our products,” “confirmation of obtainable measured data,” and “preparation of the necessary data for internal approval documents.” Please don’t hesitate to contact us.

What is Texture Measurement?

Texture measurement is a technique that transforms subjective tactile sensations into objective data.

The sense of touch people experience when handling materials, traditionally referred to as “texture”, has historically been judged subjectively by craftsmen and experts.

Texture measurement replicates actions like stroking, stretching, bending, and pressing on sophisticated testing equipment, converting ambiguous physical properties assessments into shared, objective numerical data.

This technology not only pursues comfort but also helps in preserving and passing down skilled artisans’ techniques to future generations.

Texture Measurement and KES (KAWABATA EVALUATION SYSTEM)

Developed in 1970 by Dr. Kiyoshi Kawabata and Dr. Masako Niwa, KES successfully transformed subjective tactile judgments into objective data.

Short for “KAWABATA EVALUATION SYSTEM,” KES is now commonly used in industries ranging from textiles to cosmetics, food, papermaking, and automobiles, serving as a global standard for texture evaluation.

Applications of KES

Initially focused on textile measurement, KES’s versatile texture measurement technology has been applied across diverse industries.

It’s used to evaluate the texture of food, the ergonomics of containers, the feel of cosmetics, the comfort of interiors, and even the touch of coatings, affecting various sectors including environmental and welfare industries. Centered around human experiences, the scope of KES is continually expanding into the future.

Learn about the industries where texture measurement is in demand from case studies.

Fiber

Tactile evaluation of dried laundry

| client | household goods manufacturer |

| Measurement sample | fiber |

| Introductory model | KES-F7 Thermo Labo |

Quantitative evaluation of the dry touch of laundry.

Verified with two types of towels: sunny-dried and room-dried towels.

Measured qmax values and confirmed correlation between wet and dry touch.

Evaluation of contact cold/warmth of cold mattress pad

| client | bedding manufacturer |

| Measurement sample | fiber |

| Introductory model | KES-F7 Thermo Labo |

Evaluated the “coolness” of a cold mattress pad.

Skin sensation of “warmth” or “coldness” when the skin touches the fabric, or contact cold/warmth sensation, was measured.

Evaluation of heat retention of functional innerwear

| client | Textile Product Manufacturer |

| Measurement sample | fiber |

| Introductory model | KES-F7 Thermo Labo |

Compared the warmth of multiple pieces of functional innerwear.

Evaluated the warmth retention of fabrics.

Resin

Texture evaluation of automobile interior materials (instrument panels)

| client | automaker |

| Measurement sample | resin |

| Introductory model | KES-G5 Compression Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester KES-F7 Thermo Labo NT-01 Surface Friction Tester |

Used to evaluate the texture of instrument panels.

Measured softness and smoothness to the touch, and coolness and warmth to the touch.

Evaluation of contact cold/warmth of bathroom floors

| client | Housing equipment manufacturer |

| Measurement sample | resin |

| Introductory model | KES-F7 Thermo Labo |

Evaluated the contact cold/warmth sensation when the feet touch the bathroom floor.

Measured the Qmax value, an index that evaluates the “cold” or “warm” sensation felt when the skin touches the floor.

Quality evaluation of medical wires

| client | Medical supply manufacturer |

| Measurement sample | resin |

| Introductory model | KES-SESRU Roughness/Friction Tester |

Used to compare differences in medical wire quality that cannot be determined by touch.

Evaluated for slipperiness, unevenness, and smoothness.

Non-woven Fabric

Quality control of disposable diapers

| client | Non-woven Manufacturer |

| Measurement sample | Non-woven Fabric |

| Introductory model | KES-YN1-B Large-size torsion testing machine KES-G5 Compression Tester KES-SE Friction Tester KES-F8 Air Permeability Tester KDMD-200 Baby Dummy Dolls |

Used for quality control of design.

Measurements of diaper softness, surface smoothness, and hardness when twisted.

Dummy dolls are also used to test urine leakage and diffusion by having a sample actually attached to the doll.

Evaluation of the feel of the mask

| client | hygiene products manufacturer |

| Measurement sample | Non-woven Fabric |

| Introductory model | KES-FB4-A Surface Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester |

Verified the mask’s feel against the skin.

Measured the coefficient of friction and evaluated fluffiness and flexibility.

Tissue texture and breathability evaluation

| client | paper manufacturer |

| Measurement sample | Non-woven Fabric |

| Introductory model | KES-FB4-A Surface Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester KES-F8 Air Permeability Tester |

Evaluates the tissue’s smoothness to the touch and air permeability.

Measured smoothness and roughness to the touch and breathability.

Hair

Evaluates the level of heat damage to the hair

| client | |

| Measurement sample | |

| Introductory model |

Measured tensile strength of hair damaged by heat at G1SH. The damage level is evaluated.

At the time of measurement, hair diameter was measured and cross-sectional area was calculated using SK2000, and hair was grouped so that the average cross-sectional area was equal.

Measurements were performed under the same hair conditions.

Evaluation of bending properties before and after shampoo use

| client | hair care manufacturer |

| Measurement sample | Hair |

| Introductory model | KES-FB2-S Pure Bending Tester KES-FB2-SH Single Fiber Bending Tester |

Evaluation of hair firmness after shampoo and conditioner use

| client | Cosmetics Manufacturer |

| Measurement sample | Hair |

| Introductory model | KES-SE Friction Tester KES-SESRU Roughness/Friction Tester |

Compared the feel of several shampoos and conditioners after use and after drying.

Verified which products left the hair with good finger movement.

Measured the average coefficient of friction of a hair bundle and evaluated the smoothness and firmness of the hair surface.

Leather

Seat comfort evaluation of automobile seats

| client | automaker |

| Measurement sample | Leather |

| Introductory model | KES-G5 Compression Tester |

Used to objectively evaluate the seating comfort of car seats.

Compression characteristics are measured and “softness” and “elasticity” are evaluated.

Seat comfort evaluation of automobile seats

| client | automaker |

| Measurement sample | Leather |

| Introductory model | KES-FB2-L Large bending Tester |

Used to compare genuine leather, synthetic leather, and PVC leather with a sample thickness of 1 mm or greater.

Bending hardness and recovery are measured and leather suppleness is evaluated.

Seat comfort evaluation of automobile seats

| client | automaker |

| Measurement sample | Leather |

| Introductory model | HapLog Wearable Tactile Action Sensor |

Evaluates the operability of the steering wheel.

Measured finger force when gripping the steering wheel and movement during operation.

Other

Paper texture evaluation (softness, roughness)

| client | Universities and Testing Institutes |

| Measurement sample | Paper |

| Introductory model | KES-FB2-A Pure Bending Tester KES-SE Friction Tester KES-SESRU Roughness/Friction Tester |

Used to evaluate paper texture.

Measure the hardness of the paper when bent and the roughness when touched.

Evaluation of flooring texture and durability

| client | building material manufacturer |

| Measurement sample | Wood |

| Introductory model | KES-SE Friction Tester KES-F7 Thermo Labo KK01 Scratch Tester KK02 Scratch Tester KK03 Scratch Tester |

Evaluated the feel and durability of flooring.

Verified slipperiness, warm/cold sensation, and scratchiness.

Evaluation of coolness after cosmetic application

| client | Cosmetics Manufacturer |

| Measurement sample | Liquid |

| Introductory model | Liquid |

Evaluated the characteristics of heat after cosmetic application.

Analyzed the correlation with sensory evaluation for coolness.

Major Clients of Electronic Measuring Instruments

| Domestic (in alphabetical order) | ・Asahi Kasei Corp. ・ASICS Corporation |

| International (in alphabetical order) | ・Australia ・Canada ・Czech Republic ・France ・Hong Kong ・Italy ・Netherlands ・Portugal ・Spain ・Thailand ・United States ・Brazil |

Industry-industry, industry-government-university collaboration experience

-joint development-

| KYOTO UNIVERSITY | KES Texture Tester |

| THE UNIVERSITY OF SHIGA PREFECTURE | Nanofiber Electrospinning Unit |

| Shiseido Company, Limited | HapLog |

| Toyota Motor Corporation | Dummy Doll (Custom-made for evaluation of sitting comfort of automotive seats) |

| AOKI Inc. | Slacks Robot |

| Keio University | QUANTITEXTURE |

About US

Manufacture of electronic measuring instruments

Texture measurement technology KES provides measurement equipment to evaluate samples

| Company Name | KATO TECH CO.,LTD. |

| Location | 26 Karato-cho, Nishikujo, Minami-ku, Kyoto 601-8447 Japan |

| Representative Director | Atsuko Kato |

| Established | September 1st, 1961 |

| Business Outline | 1. Electronic measuring instruments 2. Polymer material-related instruments 3. Various kinds of manufacturing instruments 4. Large Special Industrial Machinery |

Need more info ?

Surface Tester KES-FB4-A Catalog

KATO TECH CO.,LTD.

Supplier Information

- Store Name: KATO TECH CO.,LTD.

- Vendor: KATO TECH CO.,LTD.

- Address: 601-8447

Kyoto Minami-ku 26, Nishikujo Karado-cho

- Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Air Permeability Tester KES-F8 – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentAir Permeability Tester KES-F8 – KATO TECH CO.LTD.

The KES-F8 Air Permeability Tester is designed to quickly and accurately measure the breathability and permeability of a wide range of samples, from those with high permeability, such as stockings, to those with low permeability, such as synthetic leather.

Samples can be mounted in just a few seconds using the handle, and measuring is also incredibly simple.

SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

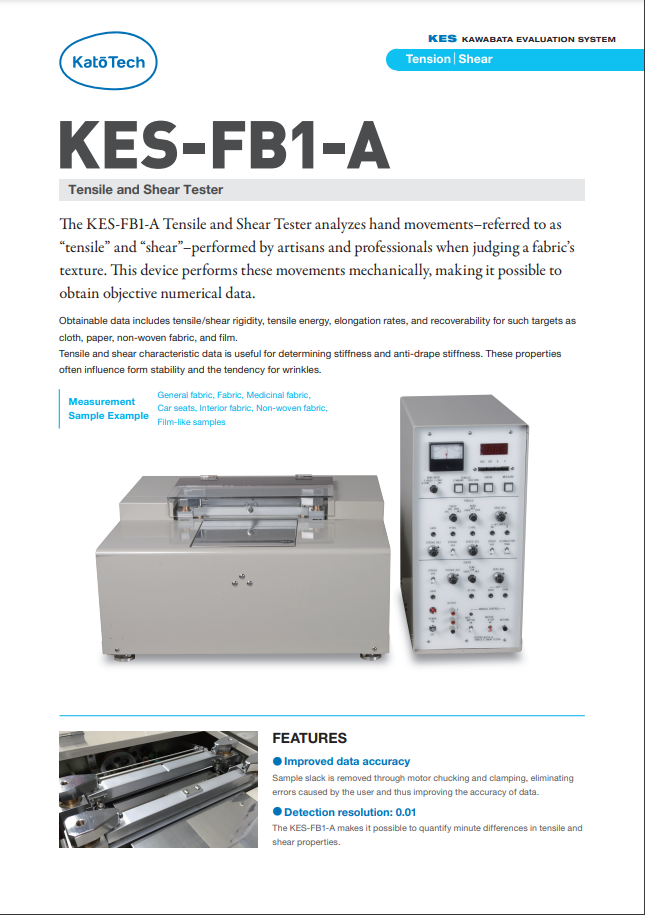

Tensile and Shear Tester KES-FB1-A/AW – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentTensile and Shear Tester KES-FB1-A/AW – KATO TECH CO.LTD.

The KES-FB1-A Tensile and Shear Tester analyzes hand movements-referred to as “tensile” and “shear”-performed by artisans and professionals when judging a fabric’s texture.

This device performs these movements mechanically, making it possible to obtain objective numerical data.

Obtainable data includes tensile/shear rigidity, tensile energy, elongation rates, and recoverability for such targets as cloth, paper, non-woven fabric, and film.

Tensile and shear characteristic data is useful for determining stiffness and anti-drape stiffness. These properties often influence form stability and the tendency for wrinkles.SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Puncture Strength Tester NDG5 – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentPuncture Strength Tester NDG5 – KATO TECH CO.LTD.

This testing machine measures the piercing strength required for a needle to penetrate a sample.

It is to measure rupture strength by applying force at a right angle, used for testing physical properties of battery separators.

The NDG5 can be used to evaluate the strength of film inside lithium-ion batteries (separators) and to measure the strength required to pierce packaging materials such as food packaging films.SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Compression Tester KES-FB3-A – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentCompression Tester KES-FB3-A – KATO TECH CO.LTD.

Compression characteristic data is useful for determining fullness and softness, smoothness, anti-drape stiffness.

The KES-FB3-A Compression Tester analyzes hand movements-particularly, pushing with a finger-performed by artisans and professionals when judging a fabric’s texture. This device performs this movement mechanically, making it possible to obtain objective numerical data.

Obtainable data includes compression rigidity, compression energy, and recoverability for such targets as general fabric, cloth, paper, and non-woven fabric.SKU: n/a - Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & Equipment

Compression Tester KES-G5 – KATO TECH CO.LTD.

Other Physical Measuring Instruments, Physical Measuring Instruments, Testing Instrument & EquipmentCompression Tester KES-G5 – KATO TECH CO.LTD.

The KES-G5 Compression Tester analyzes hand movements-particularly, movements by finger-performed by artisans and professionals when judging a fabric’s texture.

Obtainable data includes compression rigidity, compression energy, and recoverability.

The machine can be applied to a wide variety of fields and purposes, including determining the softness of disposable diapers and the hardness of mousse.SKU: n/a - Testing Equipment, Testing Instrument & Equipment

Thermo Labo KES-F7 – KATO TECH CO.LTD.

Measure cold and warm sensations by “qmax” value.

The KES-F7 Thermo Labo can be used to evaluate such products as bedding material meant to offer a feeling of coldness in summer, and underwear material meant to offer contact warmth in winter.

SKU: n/a