I-B Conveyor – NISHIMURA WORKS co. ltd.

Low maintenance, long service-life vertical bucket elevator provides gentle conveying of materials

The Nishimura I-B Conveyor is an innovative internal bucket conveyor that offers features and advantages not found in traditional outer bucket conveyors, such as exceptionally smooth loading, natural discharge, and the option of using rubber bucket materials to prevent sticking. Its structure ensures minimal impact to buckets during loading, resulting in less wear and extended service life.

Report Abuse

Description

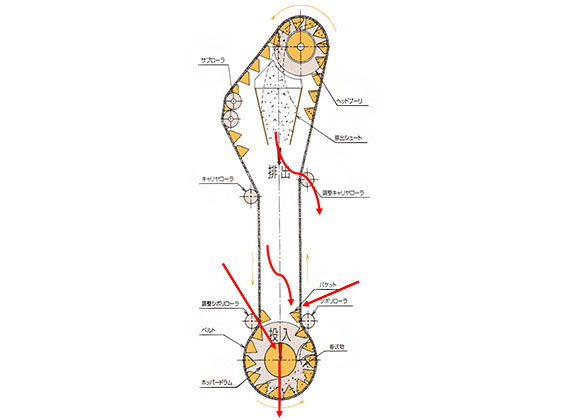

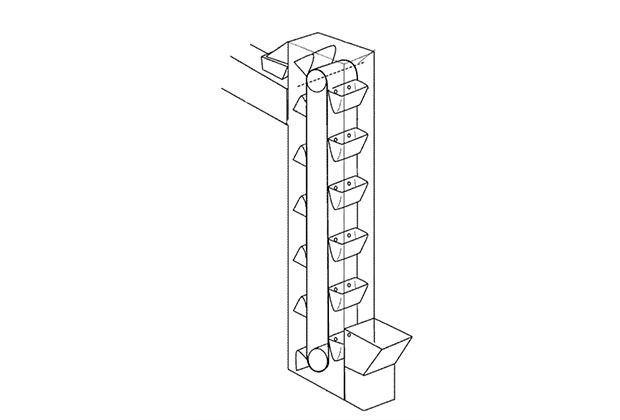

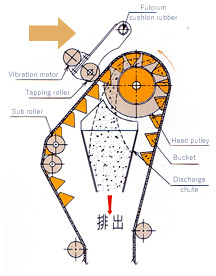

- I-B stands for Internal Bucket. This vertical conveyor has its buckets attached to the inside of the belt.

- Liquids and granules can be transported vertically.

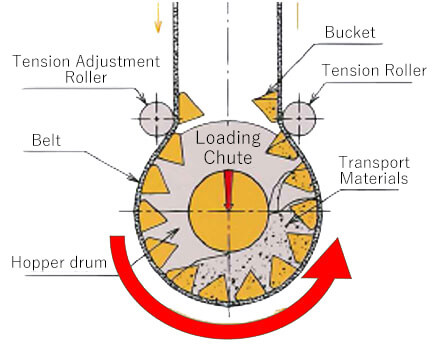

Loading in the hopper drum

As you can see in the video, the belt and buckets move together through the hopper drum.

Material to be transported is fed into the hopper drum and naturally flows into the buckets.

Reference

This I-B Conveyor has a belt width of 1200mm. It can transfer 180t/hour to the equivalent height of a nine-story building (26m.)

| Model Number | IB-120A26 |

|---|---|

| Belt width | 1,200㎜ |

| Shaft to Shaft Height | 26m |

| Power | 30kW |

| Belt speed | 40m/min |

| Transport volume 180t/h | 180t/h(133m³/h) |

| Transported material | Ferroalloys, slag-making materials |

Applications

Granulated slag, Coke, CoalLime, Iron powder, Glass, Ferroalloy, Wooden pellets, Refractory materials, Ceramics, Silica stone and sand, Gypsum

Structure

I-B Conveyor | VS. Outer bucket conveyor |

|---|---|

|  |

|

|

Loading

Smooth loading

The materials are loaded into the center of the hopper drum which rotates together with the belt and bucket. Materials smoothly flow into the buckets without impact.

Advantages of Smooth Loading

- Almost no damage to fragile materials

- Very little bucket wear

- Buckets do not fall off the belt

- Power requirement is low because there is no resistance when loading buckets

- Less loading noise than scraping method

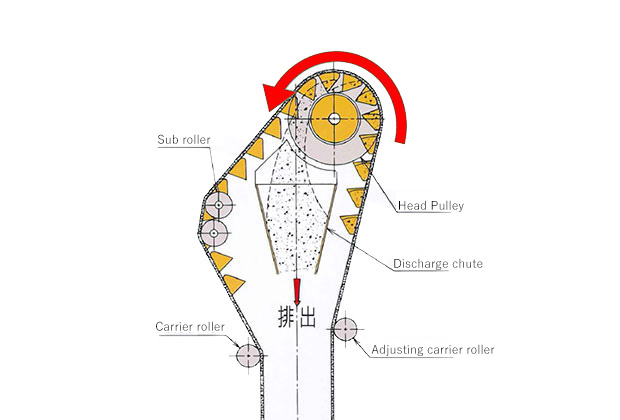

Discharge

Smooth, gentle discharge

- As the loaded bucket approaches the head pulley, its free edges contact the sides and central shaft of the pulley, forming a closed space between it and the preceding bucket.

- When the preceding bucket separates from the pulley, the material is released and naturally falls into the discharge chute.

Merits of the I-B Conveyor

- Low power-load

There is little fluctuation in power because of the natural flow of loading and unloading. - Easy to maintain

The floating hopper drum unit acts as a tension weight, lowering in position as the belt stretches, keeping tension uniform. Manual adjustment is unnecessary.

Optional Equipment

Belt tapper

A roller with a vibration motor can be placed on the outside of the belt at the discharge chute. The roller vibrates lightly, preventing conveyed materials from adhering to the bucket and causing them to fall directly into the discharge chute.

Rubber bucket

A change to rubber buckets is also effective for highly adherent products. At the head pulley, the rubber bucket edge touches the shaft, distorting the bucket. When the bucket separates from the pulley, it returns to its original shape and this causes all of the material to fall out.

Supplier Information

- Store Name: NISHIMURA WORKS Co., Ltd.

- Vendor: NISHIMURA WORKS Co., Ltd.

- Address: 849-0302

Saga Ogi City 286-4 Kakihise