Grain Cleaner – Intake Drum Sieve FDSA – Satake Corporation

Specially Designed for Separation of Large Impurities At Very High Capacities

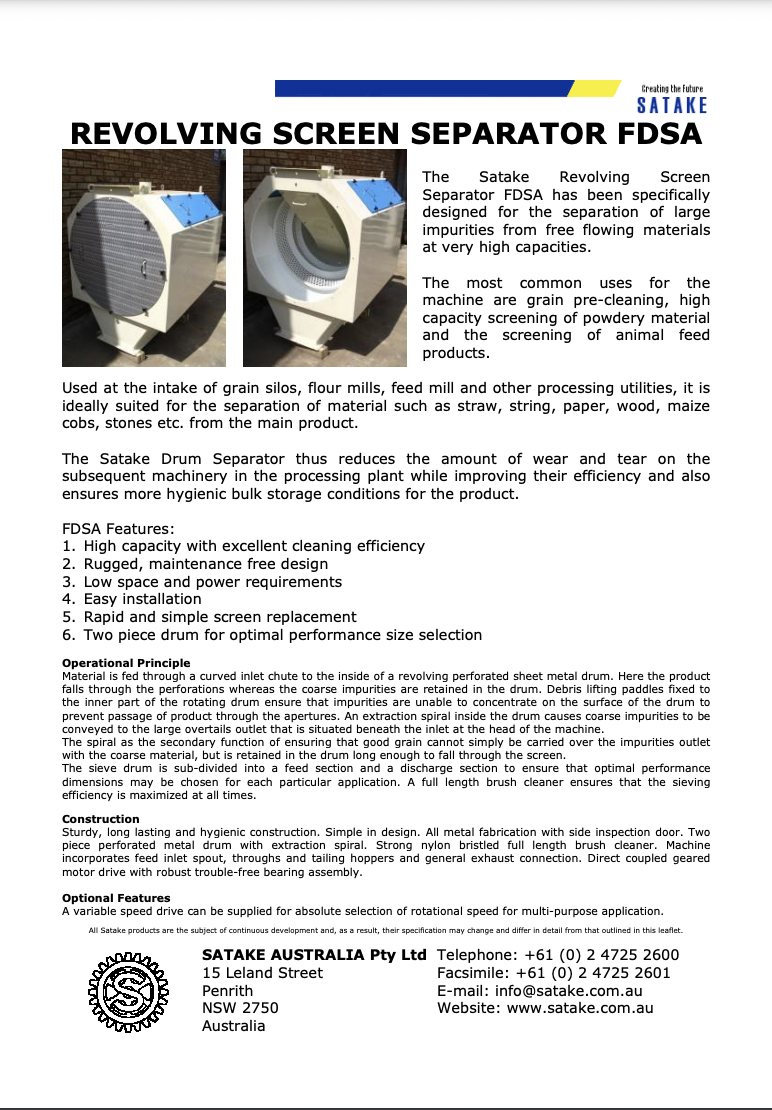

The Satake Revolving Screen Separator FDSA has been specifically designed for the separation of large impurities from free flowing materials at very high capacities.

The most common uses for the machine are grain pre-cleaning, high capacity screening of powdery material and the screening of animal feed products.

Used at the intake of grain silos, flour mills, feed mill and other processing utilities, it is ideally suited for the separation of material such as straw, string, paper, wood, maize cobs, stones etc. from the main product.

The Satake Drum Separator, thus reduces the amount of wear and tear on the subsequent machinery in the processing plant while improving their efficiency and also ensures more hygienic bulk storage conditions for the product.

Report Abuse

Details

1. High capacity with excellent cleaning efficiency

2. Rugged, maintenance free design

3. Low space and power requirements

4. Easy installation

5. Rapid and simple screen replacement

6. Two piece drum for optimal performance size selection

Manufacturing and sales of processing machinery and equipment for rice, wheat and corn

Satake Corporation is a manufacturer and distributor of rice processing machinery and equipment. Their product line includes drying and preparation equipment for farmers, rice cooking equipment, and rice flour processing machinery. Additionally, the company produces wheat and corn-related equipment, such as flour milling machines and de-moistening machines. Satake also produces food products like “GABA Raku Meshi” packaged rice, as well as aquatic organism inspection equipment and industrial machinery.

Scope of Business

In publications on rice milling technology anywhere in the world, you will come across the name Satake. All over the world Satake has become synonymous with rice milling.

Country Elevator

After rice is harvested, it must be dried and then stored in its unhulled state before husking. Country elevators perform functions that have made a significant contribution to increasing the productivity of farms.

Rice Milling Unit

It has a hygienic structure which eliminates residual rice remaining inside the vessel at the end of the milling batch.

The machine is suitable for the miller who produces various rice products in small batch sizes.

Color Sorter

This equipment rejects foreign materials that are mixed in with grains of rice or wheat. A sensor detects the foreign material which is then ejected by air at high velocities.

IH Cooking Line

This IH (induction heating) rice cooking system with round pots and a pot racking system is the first in the industry and provides the best cooking quality. Also, the type of rice for each pot can be individually selected.

Need more info ?

REVOLVING SCREEN SEPARATOR FDSA

Satake Corporation

Supplier Information

- Store Name: Satake Corporation

- Vendor: Satake Corporation

- Address: 739-0045

Hiroshima Higashi Hiroshima 2-30,Saijo Nishi, Honmachi

- Food & Beverage Machinery, Grain Product Making Machines, Other Rice Processing Machines, Rice Processing Machine

Rice Flour Roller Mill – Satake Corporation

Food & Beverage Machinery, Grain Product Making Machines, Other Rice Processing Machines, Rice Processing MachineRice Flour Roller Mill – Satake Corporation

New Milling Equipment for minute granularity products Compact design, Ultra-fine granularity, for Various grains

2 Features

1. Wet-type milling capability (with optional hot air generator)

2. Easy installation and relocationSKU: n/a - Food & Beverage Machinery, Grain Product Making Machines, Rice Mill Dryer, Rice Processing Machine

rice mill dryer-Far-infrared grain dryer “TIARA” – Satake Corporation

Food & Beverage Machinery, Grain Product Making Machines, Rice Mill Dryer, Rice Processing Machinerice mill dryer-Far-infrared grain dryer “TIARA” – Satake Corporation

The progress of the impressions is indicated by LED lights.

Once the moisture meter calculates the moisture content of the grain, LED lights built into the left and right sides of the control panel indicate the moisture range.

SKU: n/a - Food & Beverage Machinery, Grain Product Making Machines, Rice Mill Dryer, Rice Processing Machine

rice mill dryer-High durability series “SAXES” grain dryer – Satake Corporation

Food & Beverage Machinery, Grain Product Making Machines, Rice Mill Dryer, Rice Processing Machinerice mill dryer-High durability series “SAXES” grain dryer – Satake Corporation

SAXES series, a new generation of dryers and hullers.

It meets the expectations of large scale producers such as farmers’ groups.

Unprecedented level of durability (compared to our previous models).

Attention was paid to every detail of parts, and materials were changed by adopting stainless steel and other materials, as well as heat treatment to enhance wear resistance.

The use of high-grade products has improved durability compared to previous models.

Taking the “SAXES” to a new dimension with cutting-edge technologySKU: n/a - Food & Beverage Machinery, Grain Product Making Machines, Rice Mill Dryer, Rice Processing Machine

rice mill dryer-High durability series “SAXES V” grain dryer – Satake Corporation

Food & Beverage Machinery, Grain Product Making Machines, Rice Mill Dryer, Rice Processing Machinerice mill dryer-High durability series “SAXES V” grain dryer – Satake Corporation

SAXES-V has evolved, and SAXES-V is now available.

In 2018, a new brand “SAXES” was launched as a high durability series for large scale producers, with a completely different concept and design from the previous machines.

SKU: n/a