Activated carbon for high adsorption MAXSORB – Kansai Coke and Chemicals Company Limited

Three times the specific surface area of conventional activated carbon can be achieved! MAXSORB has a higher adsorption performance compared to conventional steam-activated carbon.

Alkaline activated carbon ””MAXSORB”” has a higher specific surface area than conventional(steam etc.) activated carbon. For example, a product whose specific surfacr area is more than 3,000 square meters per gram is available, which is three times higher adsorption performance compared to conventional steam-activated carbon.

There are various kinds of shape in MAXSORB products such as powder, granular, fiber and pellet.

Report Abuse

Features

- Three times the specific surface area of ordinary activated carbon!

- We are developing not only powder but also fibrous activated carbon!

- A wide variety of raw materials, activation conditions, and post-treatment processes are used to create a lineup of products with improved trihalogen adsorption performance, even with steam activated charcoal.

Applications / Examples

- High-capacity capacitor electrodes

- Water purifiers

- Methane storage

- Catalyst carriers

- High-performance deodorizers

- Adsorption heat pumps

- Gas masks

- Protective clothing

- Hydrogen storage

- VOC removal

- Precious metal recovery

- Rare gas adsorption

- Medical/Healthcare

What is ACTIVATED CARBON?

ACTIVATED CARBON is a carbonized adsorbent which has a lot of micropore formed by reaction of gas or chemicals at high temperature.

It is said that three different types of pore have each different role.

- Micro pore : <2nm

- Meso pore : 2~50nm

- Macro pore : 50nm<

The specific surface area of conventional activated carbon is about 1000m2/g.

This size is equivalent to 5 tennis courts.

We have higher surface area activated carbon whose surface area has more than 2,000m2/g (MAXSORB(R)), compared to standard activated carbon.

How to manufacture ACTIVATED CARBON

ACTIVATED CARBON is manufactured by carbonizing raw materials such as wood chips, coconut shells, and coal at high temperature and then making pore in the carbon through activation process.

There are two main methods of manufacturing activated carbon: gas-activated and chemical-activated.

We have both type of activated carbon : gas-activated carbon using steam and chemical-activated carbon using alkali metal compounds (KOH).

The above activated carbon is then washed, particle-size adjusted, and heat-treated as necessary.

What is MAXSORB® ?

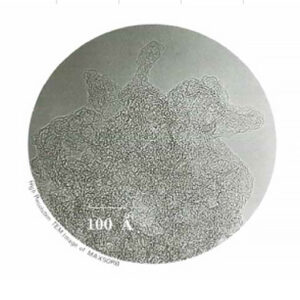

High surface area activated carbon (MAXSORB®) is an alkali (KOH)-activated carbon that Kansai Coke and Chemicals Co., Ltd. succeeded in mass-producing advanced in the world in 1992.

Point1:HIGH SURFACE AREA

While most of general steam activated carbon products are its surface area of around 1,000m2/g, some alkali activated carbon products have its surface area of more than 2,000m2/g, which means that they have high adsorption performance.

Point2: SURFACE PROPERTIES

One of the characteristics of alkali activated carbon is that it has more edge surfaces than steam activated carbon.

These edge surfaces of carbon are said to be chemically active, and the evaluation of the edges can be used as a guide to the reaction activity of the carbon.

The end edge surfaces can be used, for example, as an electrode material for Electric Double Layer Capacitors, and residual chlorine removal in water purifiers.

※Explanation of graph

1. The edge of carbon is evaluated by our original method.

2. Specific Surface Area VS Active Point

when a steam activated carbon(1,000m2/g) is set to “1

(Plot: actual measurement, line: image)

Point3: SHAPE

We have powder, granular, fibrous, and pellet forms, and can make proposals according to the customer’s application.

Kansai Coke and Chemicals Company, Limited

Treat people as assets, treat nature as an asset, and create new value

Our main products-coke for steel-making, fuel gas, and a various chemical products-are not normally used directly by consumers. However, they are the raw materials for myriad products and contribute to peoples’ daily lives.

These days, we are aiming to use our knowledge of carbon chemistry and energy chemistry to contribute to society by launching businesses that cater to the changing needs of the times, such as manufacturing electrode materials for electric double-layer capacitors; precision cleaning of semiconductors, FPDs, and solar cell manufacturing equipment; and environmental analyses, materials analyses, and volatile organic compound (VOC) assessments.

Need more info ?

High-performance activated carbon (MaxSorb®)

Kansai Coke and Chemicals Company Limited

Supplier Information

- Store Name: Kansai Coke and Chemicals Company, Limited

- Vendor: Kansai Coke and Chemicals Company, Limited

- Address: 661-0976

Amagasaki-shi JRE Amagasaki Front Bldg. 8F

1-2-6 Shioe

- Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

Activated carbon for metal adsorption MAXSORB HF-Series – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsActivated carbon for metal adsorption MAXSORB HF-Series – Kansai Coke and Chemicals Company Limited

This activated carbon has a much higher amount of acidic surface functional groups than conventional activated carbon by utilizing our know-how and technology of alkaline activation. It demonstrates high performance not only for metals, but also for chlorine, ammonia, chloramine removal, etc.

SKU: n/a - Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

Activated carbon for electrodes of energy storage devices (supercapacitors, etc.) MAXSORB – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsActivated carbon for electrodes of energy storage devices (supercapacitors, etc.) MAXSORB – Kansai Coke and Chemicals Company Limited

High-performance activated carbon MAXSORB has become synonymous with electrode materials for high-capacity capacitors due to its characteristic high specific surface area and active point.

In addition, it is expected to demonstrate high performance not only in capacitors but also in electrode materials for next-generation batteries.

SKU: n/a - Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

High-performance activated carbon for water purifiers MAXSORB – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsHigh-performance activated carbon for water purifiers MAXSORB – Kansai Coke and Chemicals Company Limited

High-performance activated carbon MAXSORB has higher adsorption performance than general activated carbon and contributes to water purification, such as in household water purifiers.

SKU: n/a - Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

High performance activated carbon for PFAS removal – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsHigh performance activated carbon for PFAS removal – Kansai Coke and Chemicals Company Limited

The equilibrium adsorption capacity for organic fluorine compounds is approximately 10 times higher than that of conventional steam-activated carbon.

Kansai Coke and Chemicals Company, Limited’s high-performance activated carbon for PFAS removal (development product) demonstrates an equilibrium adsorption capacity for PFAS that is 10 times higher than that of conventional steam-activated carbon.

SKU: n/a

Features

- Three times the specific surface area of ordinary activated carbon!

- We are developing not only powder but also fibrous activated carbon!

- A wide variety of raw materials, activation conditions, and post-treatment processes are used to create a lineup of products with improved trihalogen adsorption performance, even with steam activated charcoal.

Applications / Examples

- High-capacity capacitor electrodes

- Water purifiers

- Methane storage

- Catalyst carriers

- High-performance deodorizers

- Adsorption heat pumps

- Gas masks

- Protective clothing

- Hydrogen storage

- VOC removal

- Precious metal recovery

- Rare gas adsorption

- Medical/Healthcare

What is ACTIVATED CARBON?

ACTIVATED CARBON is a carbonized adsorbent which has a lot of micropore formed by reaction of gas or chemicals at high temperature.

It is said that three different types of pore have each different role.

- Micro pore : <2nm

- Meso pore : 2~50nm

- Macro pore : 50nm<

The specific surface area of conventional activated carbon is about 1000m2/g.

This size is equivalent to 5 tennis courts.

We have higher surface area activated carbon whose surface area has more than 2,000m2/g (MAXSORB(R)), compared to standard activated carbon.

How to manufacture ACTIVATED CARBON

ACTIVATED CARBON is manufactured by carbonizing raw materials such as wood chips, coconut shells, and coal at high temperature and then making pore in the carbon through activation process.

There are two main methods of manufacturing activated carbon: gas-activated and chemical-activated.

We have both type of activated carbon : gas-activated carbon using steam and chemical-activated carbon using alkali metal compounds (KOH).

The above activated carbon is then washed, particle-size adjusted, and heat-treated as necessary.

What is MAXSORB® ?

High surface area activated carbon (MAXSORB®) is an alkali (KOH)-activated carbon that Kansai Coke and Chemicals Co., Ltd. succeeded in mass-producing advanced in the world in 1992.

Point1:HIGH SURFACE AREA

While most of general steam activated carbon products are its surface area of around 1,000m2/g, some alkali activated carbon products have its surface area of more than 2,000m2/g, which means that they have high adsorption performance.

Point2: SURFACE PROPERTIES

One of the characteristics of alkali activated carbon is that it has more edge surfaces than steam activated carbon.

These edge surfaces of carbon are said to be chemically active, and the evaluation of the edges can be used as a guide to the reaction activity of the carbon.

The end edge surfaces can be used, for example, as an electrode material for Electric Double Layer Capacitors, and residual chlorine removal in water purifiers.

※Explanation of graph

1. The edge of carbon is evaluated by our original method.

2. Specific Surface Area VS Active Point

when a steam activated carbon(1,000m2/g) is set to “1

(Plot: actual measurement, line: image)

Point3: SHAPE

We have powder, granular, fibrous, and pellet forms, and can make proposals according to the customer’s application.

Kansai Coke and Chemicals Company, Limited

Treat people as assets, treat nature as an asset, and create new value

Our main products-coke for steel-making, fuel gas, and a various chemical products-are not normally used directly by consumers. However, they are the raw materials for myriad products and contribute to peoples’ daily lives.

These days, we are aiming to use our knowledge of carbon chemistry and energy chemistry to contribute to society by launching businesses that cater to the changing needs of the times, such as manufacturing electrode materials for electric double-layer capacitors; precision cleaning of semiconductors, FPDs, and solar cell manufacturing equipment; and environmental analyses, materials analyses, and volatile organic compound (VOC) assessments.

Need more info ?

High-performance activated carbon (MaxSorb®)

Kansai Coke and Chemicals Company Limited

Supplier Information

- Store Name: Kansai Coke and Chemicals Company, Limited

- Vendor: Kansai Coke and Chemicals Company, Limited

- Address: 661-0976

Amagasaki-shi JRE Amagasaki Front Bldg. 8F

1-2-6 Shioe

- Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

Activated carbon for metal adsorption MAXSORB HF-Series – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsActivated carbon for metal adsorption MAXSORB HF-Series – Kansai Coke and Chemicals Company Limited

This activated carbon has a much higher amount of acidic surface functional groups than conventional activated carbon by utilizing our know-how and technology of alkaline activation. It demonstrates high performance not only for metals, but also for chlorine, ammonia, chloramine removal, etc.

SKU: n/a - Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

Activated carbon for electrodes of energy storage devices (supercapacitors, etc.) MAXSORB – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsActivated carbon for electrodes of energy storage devices (supercapacitors, etc.) MAXSORB – Kansai Coke and Chemicals Company Limited

High-performance activated carbon MAXSORB has become synonymous with electrode materials for high-capacity capacitors due to its characteristic high specific surface area and active point.

In addition, it is expected to demonstrate high performance not only in capacitors but also in electrode materials for next-generation batteries.

SKU: n/a - Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

High-performance activated carbon for water purifiers MAXSORB – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsHigh-performance activated carbon for water purifiers MAXSORB – Kansai Coke and Chemicals Company Limited

High-performance activated carbon MAXSORB has higher adsorption performance than general activated carbon and contributes to water purification, such as in household water purifiers.

SKU: n/a - Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical Goods

High performance activated carbon for PFAS removal – Kansai Coke and Chemicals Company Limited

Catalysts & Auxiliaries, Chemical Auxiliaries, Chemical GoodsHigh performance activated carbon for PFAS removal – Kansai Coke and Chemicals Company Limited

The equilibrium adsorption capacity for organic fluorine compounds is approximately 10 times higher than that of conventional steam-activated carbon.

Kansai Coke and Chemicals Company, Limited’s high-performance activated carbon for PFAS removal (development product) demonstrates an equilibrium adsorption capacity for PFAS that is 10 times higher than that of conventional steam-activated carbon.

SKU: n/a