Modular Belt Conveyor (P-Con) – Nikko Co. Ltd.

Modular Belt Conveyor (P-Con): Versatile and Efficient Solution for Various Industries

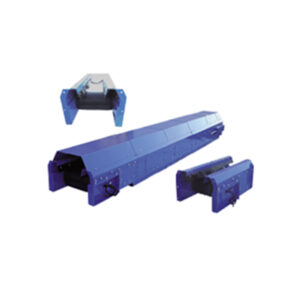

The Modular Belt Conveyor (P-Con) is a product title in the manufacturing industry, offering various features and options to cater to different specifications and applications. It comes in different types, including Boat Bottom Type for bulk materials such as soil, gravel, sand, crushed stone, compost, wood chips, cans, waste glass, straw, wheat, waste disposal, sludge, and others; Climber Type for inclined transportation of bulk materials with an inclination angle of approximately 25° to 45°; and Flat Type for bagged and boxed materials such as cardboard boxes, trays, plastic containers, and other items.

The conveyor has been successfully used in various applications, including environmental recycling of waste wood, cans, bottles, plastic waste, paper, tires, electronic waste, gypsum board waste, glass waste, construction waste, incineration ash, sludge, waste packaging materials, shredder dust, municipal waste, organic waste, wood chips, and textile waste including old cloth, bulky waste, and rubber waste; livestock farming of compost, chicken manure, pig manure, cow manure, fertilizers, feed, composting, feeding, cultivation soil, and food waste; and industrial machinery for forging, pressing, resin molding, machine tools, iron and metal scrap, aluminum, ceramics, castings, shot blasting, iron and metal cuttings, and more. It is also widely used in the iron and steel and ceramic industries for iron dust, slag, castings, bricks, tiles, cement, limestone, and clay.

Report Abuse

Product Title: Modular Belt Conveyor (P-Con)

Features

– Length can be adjusted in 10-cm increments

– Can be selected according to specifications and applications

Main Transported Items

– Boat-shaped: Suitable for transporting bulk materials such as soil, gravel, sand, crushed stone, compost, wood chips, cans, waste glass, straw, wheat, waste disposal, sludge, and others.

– Climbing type: Specifically designed for steep incline transportation of bulk materials (angle of inclination: approximately 25° to 45°).

– Flat type: Suitable for transporting bagged and boxed items such as cardboard boxes, trays, plastic containers, and bags.

Transported Items by Application

– Environmental Recycling Related: Waste wood, cans/bottles, PET bottles, waste plastics, waste paper, used tires, electronic waste, waste gypsum boards, waste glass, construction waste, incineration ash, sludge, waste packaging materials, shredder dust, municipal waste, organic waste, wood chips, fiber waste (including old cloth), bulky waste, rubber waste.

– Livestock Related: Compost, chicken manure, pig manure, cow manure, fertilizer, animal feed, compost, feeding, potting soil, food waste.

– Industrial Machinery Related: Forging, press (product 1, waste 2), plastic molding (product 1, waste 2), machine tools, iron/metal scrap.

Our Strengths

We have cultivated through the development of asphalt plants and concrete plants.

We support new construction of a wide variety of plants with our technical and support capabilities.

CORE TECHNOLOGIE

We create valuable products that benefit society at large with our four core technologies that support the world’s infrastructure.

Mixing

Kneading of all kinds of materials according to your requirements

We propose the best mixer for our customers according to the type of raw material and its application. By devising the shape of the blades and rotation speed, we can produce ultra-high-strength concrete, which is difficult to knead, and can also be applied to other fields, such as tsukudani kelp.

Heating

Realization of temperature control matched to materials

We meet the heating needs for a wide variety of materials and a wide range of temperatures with our integrated engineering services, including burners that can form a stable flame even in harsh combustion environments through the use of our unique flame retention mechanism, combustion furnaces, exhaust gas treatment equipment, material handling equipment, and temperature control equipment.

Transportation

Based on a track record of 300,000 units shipped

We design conveyor belt conveyors and other conveying equipment used in a wide variety of fields, including construction, civil engineering, agriculture, livestock, industrial waste treatment, food, chemicals, steel, and more. We have expanded our product lineup by modularizing products and automating production lines, and have established a mass production system with short delivery times.

Control

Designing and Manufacturing the “Brains” of Plants and Machinery

The use of control technology, which is the “brain” of equipment, is indispensable for the stable operation of plants with less environmental impact. The NIKKO Group has been involved in more than 4,000 control panels and control systems in Japan and overseas, and utilizes these technologies in fields such as asphalt, concrete, chemicals, semiconductors, and biomass power generation.

Supplier Information

- Store Name: Nikko Co., Ltd.

- Vendor: Nikko Co., Ltd.

- Address: 6748585

Hyogo Akashi-shi Eigashima

Okubo-cho

- Belt Conveyor, Conveyor, Industrial Machinery, Rubber Belt Conveyor

Super Modular Conveyor (SMA, SM) – Nikko Co. Ltd.

Belt Conveyor, Conveyor, Industrial Machinery, Rubber Belt ConveyorSuper Modular Conveyor (SMA, SM) – Nikko Co. Ltd.

Optimal for lightweight material handling. Customizable length in 10cm increments. Suitable for various types of conveyance, including boat-shaped, incline, and flat conveyors. Proven track record in recycling, livestock, and industrial machinery sectors.

Introducing the Super Modular Conveyor (SMA, SM), a product designed for lightweight material handling. With customizable lengths in increments of 10 cm, it can be tailored to suit your specific needs. The SMA, SM is suitable for various types of conveying, including boat-type for bulk materials such as PET bottles, waste plastics, cans, glass, straw, barley, waste, fertilizer, feed, and others. It is also ideal for inclined conveying of cans, PET bottles, waste plastics, and more. This versatile conveyor has been successfully employed in various industries, including environmental recycling, livestock farming, industrial machinery, iron and steel, grain and food, logistics and packaging materials, fisheries, and civil engineering and construction.

SKU: n/a - Belt Conveyor, Conveyor, Industrial Machinery

Super Wide Conveyor (SW) – Nikko Co. Ltd.

Safe and versatile conveyor system for various industries. Ideal for transporting a wide range of materials, from agricultural products to industrial waste. Efficient and reliable solution for your manufacturing needs.

Super Wide Conveyor (SW) is a belt conveyor designed for indoor use with a press frame type safety design and a dust-proof, environmentally-friendly structure.

Main Types of Conveyed Materials:

Boat-shaped: Suitable for conveying bulk materials such as grains, animal feed, chemical fertilizers, cans, PET bottles, dehydrated cakes, powders, and others.

Flat: Ideal for sorting lines, handling sorted cans, PET bottles, waste plastics, mixed waste, and other items.Successful Conveyed Materials by Application:

Environmental Recycling:

– Waste wood

– Cans and bottles

– PET bottles

– Waste plastics

– Waste paper

– Waste tires

– E-waste

– Waste gypsum boards

– Waste glass

– Construction waste

– Incineration ash

– Sludge

– Waste packaging materials

– Shredder dust

– Municipal waste

– Organic waste

– Wood chips

– Fiber waste (including old cloth)

– Bulky waste

– Rubber wasteLivestock-related:

– Compost

– Chicken manure

– Pig manure

– Cow manure

– Fertilizers

– Animal feed

– Compost

– Feeding

– Cultivation soil

– Food wasteIndustrial Machinery-related:

– Forging

– Press (Product 1, Waste 2)

– Plastic molding (Product 1, Waste 2)

– Machine tools

– Iron and metal scrap (Sheet)

– Iron and metal scrap (Screw)

– Iron and metal scrap (Powder)SKU: n/a